Method for reduction of tobacco specific nitrosamines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

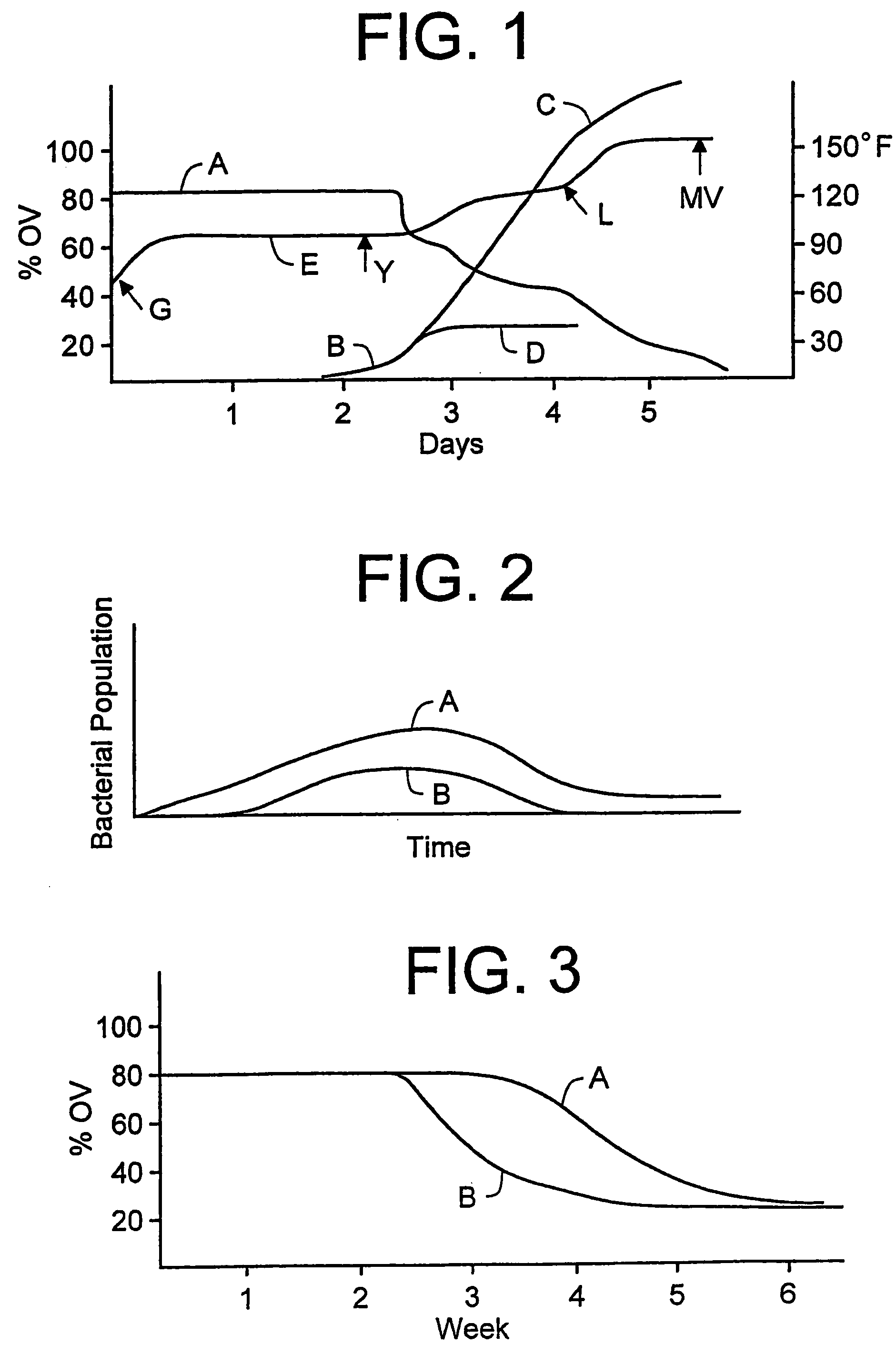

Image

Examples

example i

Antibacterial Lavage

[0044] Bright tobacco from the 5th leaf position (tip) was harvested and loaded into standard Bulktobac curing racks (approximately 70 lbs. per rack). Individual racks were immersed in 70% ethanol for either 1 or 5 minutes then rinsed in water. After draining thoroughly the treated tobacco along with untreated control material was cured in a Bulktobac 32-rack curing barn equipped with a heat exchanger. A standard flue-curing profile was followed and the resultant tobaccos were lyophilized, ground and assayed for microbial counts. The results indicated that the ethanol treatment reduced the bacterial load in a dose dependent manner 1 to 2 orders of magnitude as compared to the control for the 1 and 5 minutes treatments, respectively. That is, the control exhibited a 108 count whereas the 1 minute treatment exhibited a 107 count and the 5 minute treatment exhibited a 106 count. Similar results were achieved for treatment of the tobacco with 10.7 ppm ClO2 in aqueou...

example ii

Alkaline Lavage

[0054] The “Carbonate Lavage”—Freshly stalk-cut harvested burley (Tn90) plants were hung on a stick, 5 plants per stick and hung on a scaffold, whereupon, leaves were sprayed until run-off with an aqueous solution of either 1% or 2% (weight / volume) of NaHCO3 (sodium bicarbonate) and allowed to dry and wilt for three days and then hung in a conventional air-curing barn. Untreated controls were included. Once cured, the tobacco was dried (fixed) by passing dry air about the cured tobacco, preferably at approximately 85° F. By two weeks, older leaves (at the lower stalk positions) had become so brown as to be undistinguishable in pigmentation from untreated leaves that had cured for at least four to six weeks. The browned bicarbonate-treated leaves remained moist and pliable, in contrast to the dry and friable lamina that had been equivalently browned by conventional curing. Leaves at higher stalk positions of treated plants, i.e., developmentally younger leaves, had un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com