Piston type aircraft engine

a technology of aircraft engine and propeller, which is applied in the direction of piston type power plants, mechanical devices, fuel injection devices, etc., can solve the problems of the engine that was developed for use, the engine that is not suitable for use in modern light and ultralight airplanes, and the use of v-type engines in modern aircraft provides challenges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

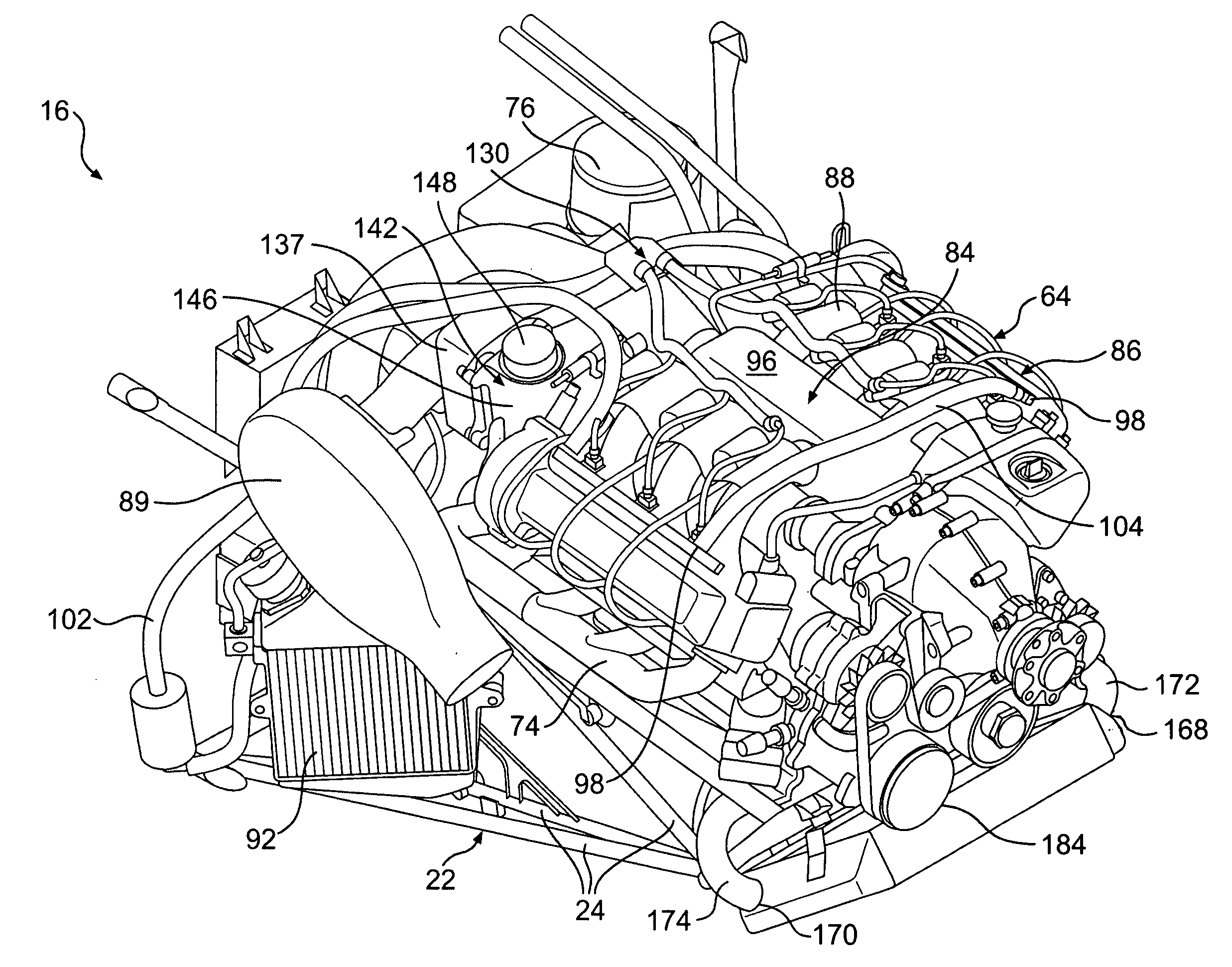

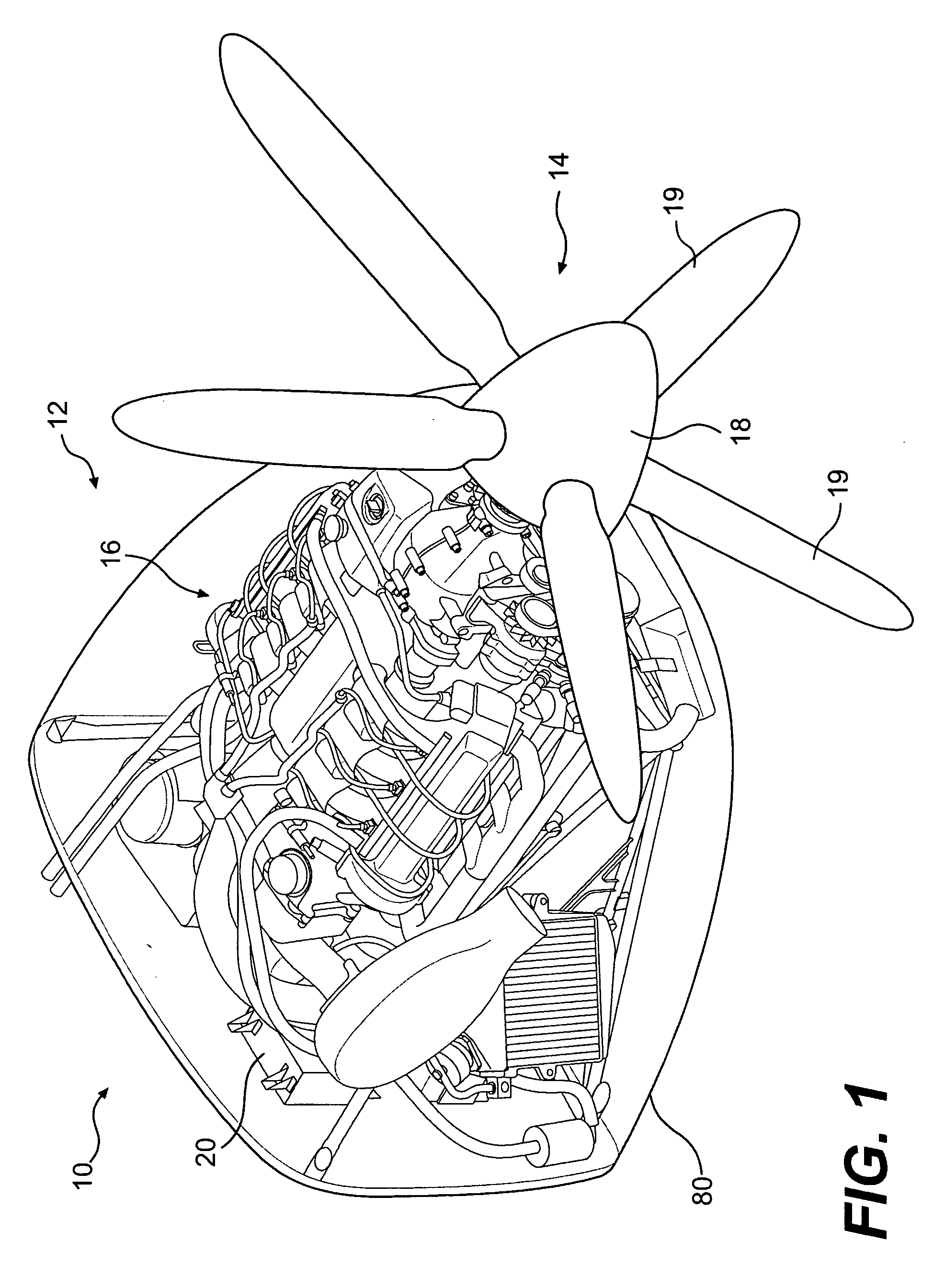

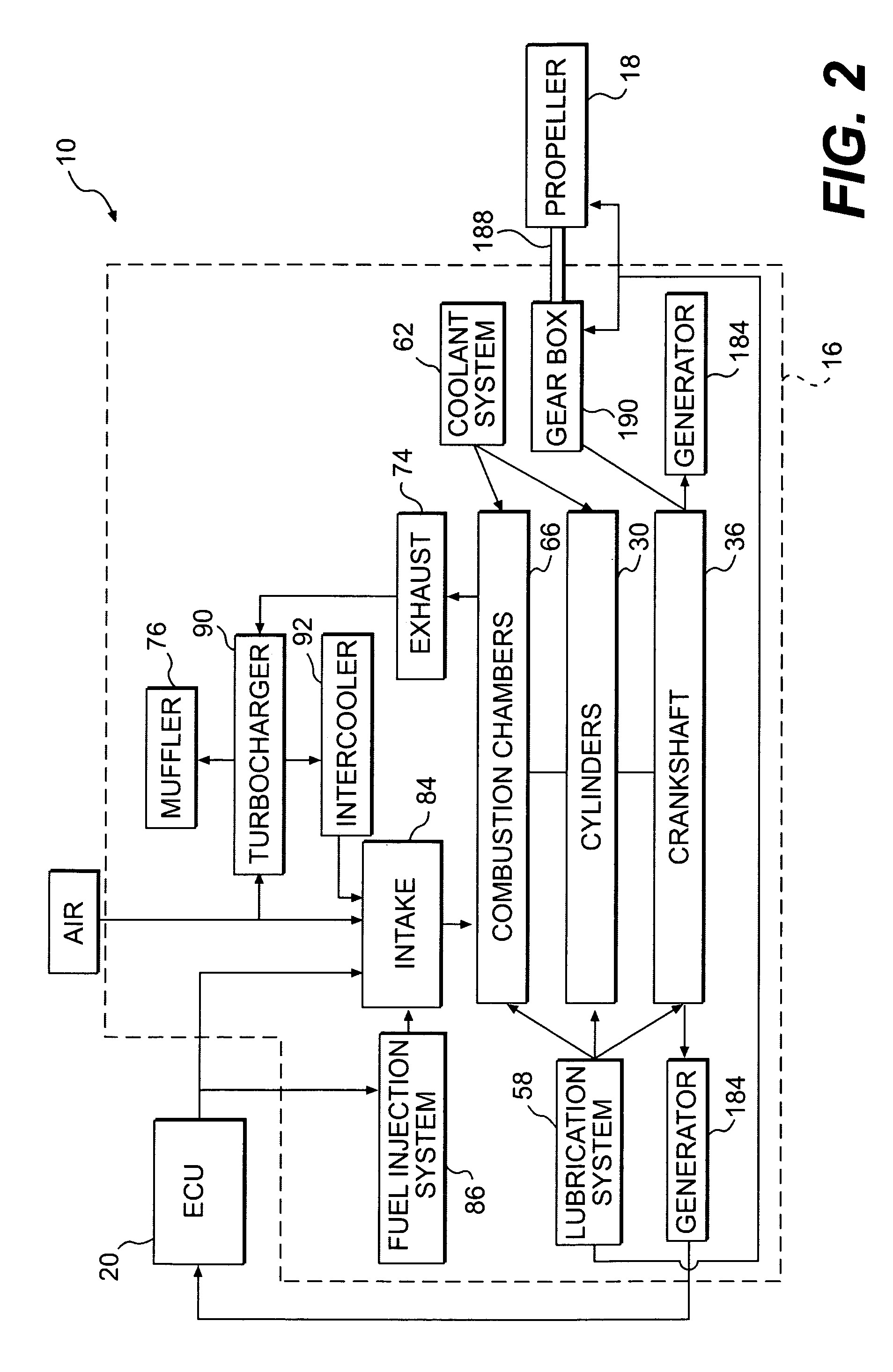

[0052]FIGS. 1 and 2 show at least one embodiment of a propulsion assembly 10 of the present invention. As shown in FIG. 1, the propulsion assembly 10 is suitable for placement in an aircraft 12 for propelling the aircraft 12. Only a front portion 14 (or nose) of the aircraft 12 is shown. In the preferred embodiment, the aircraft 12 is a light or ultralight airplane, preferably of the privately-owned type. Of course, the present invention is not limited to use with a light or ultralight aircraft. As should be appreciated by those skilled in the art, the invention may be used in any suitable aircraft, whether large or small, privately or commercially owned. The wide variety of aircraft for which the invention is designed lend to the broad scope of the invention.

[0053] The propulsion assembly 10 includes an internal combustion engine 16, a propeller shaft 188 that is operatively connected to the engine 16, and an electronic control unit (“ECU”) 20 that is electrically connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com