Plasma processing apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

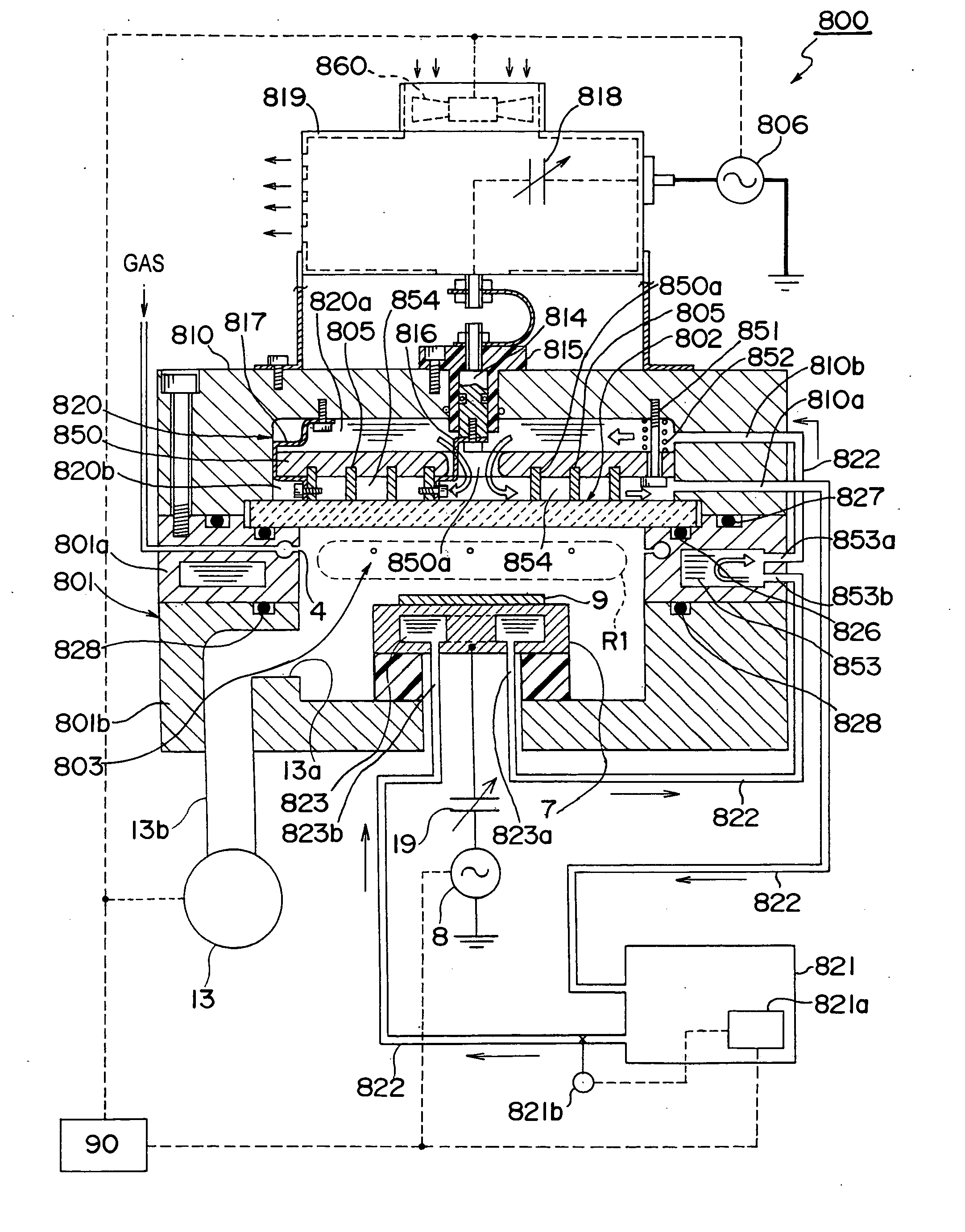

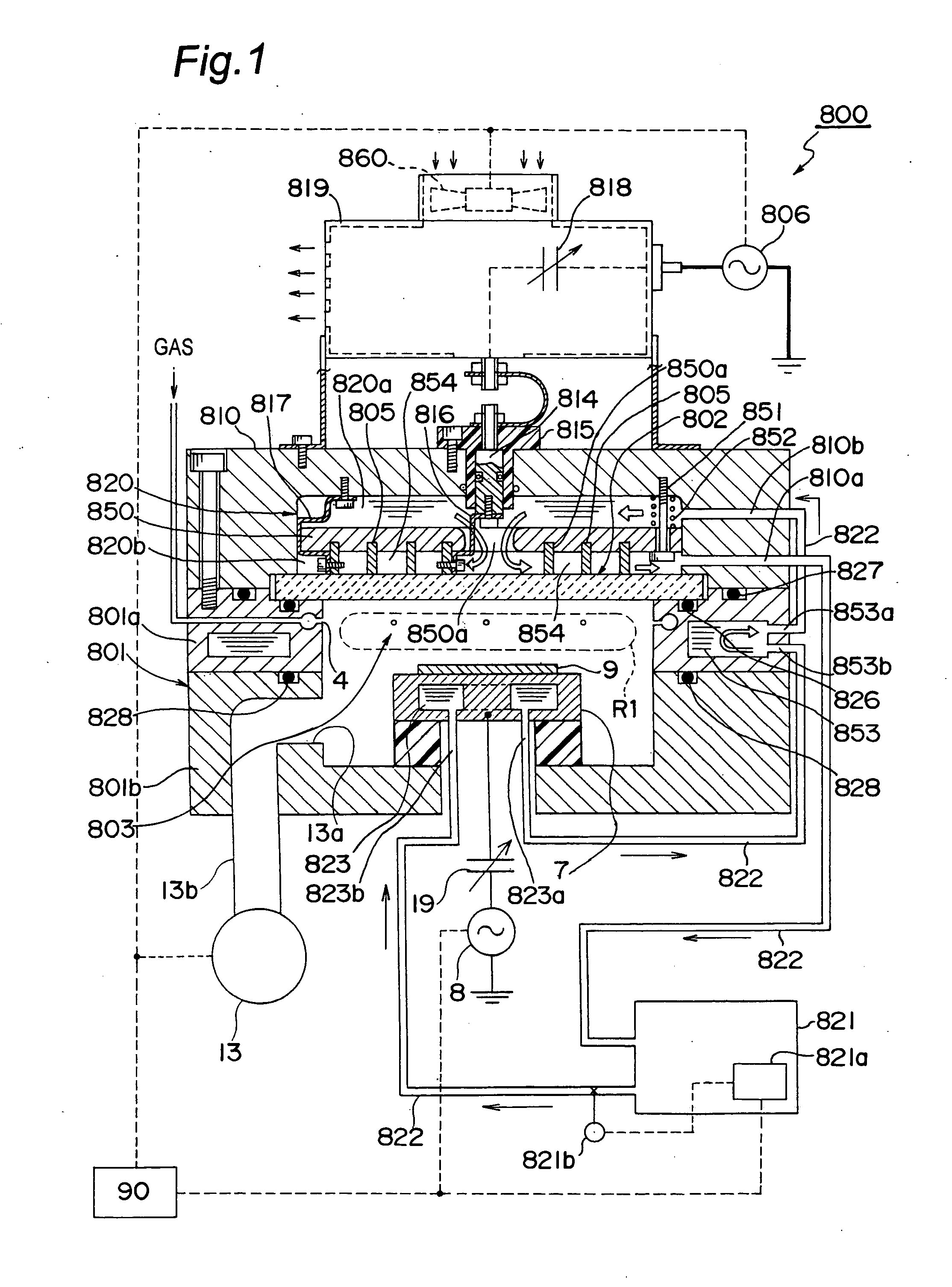

[0080] A schematic sectional view of a plasma processing apparatus 800 which is an example of a plasma processing apparatus according to a first embodiment of the present invention is shown in FIG. 1.

[0081] As shown in FIG. 1, the plasma processing apparatus 800 is equipped with a vacuum vessel 801 which has an opening at the top thereof and generally cylindrical shaped, and a dielectric window (quartz plate) 802 which is formed of a generally disc-shaped dielectric material (e.g., quartz) and which is provided so as to close the opening at the top of the vacuum vessel 801, where a processing chamber 803 is formed which is a space closed by the vacuum vessel 801 and the dielectric window 802 and a space where plasma processing is performed.

[0082] Further, as shown in FIG. 1, the vacuum vessel 801 is divided into a lower vacuum vessel 801b, which is a lower part of the generally cylindrical-shaped bottomed member, and an upper vacuum vessel 801a, which is its upper portion and annu...

second embodiment

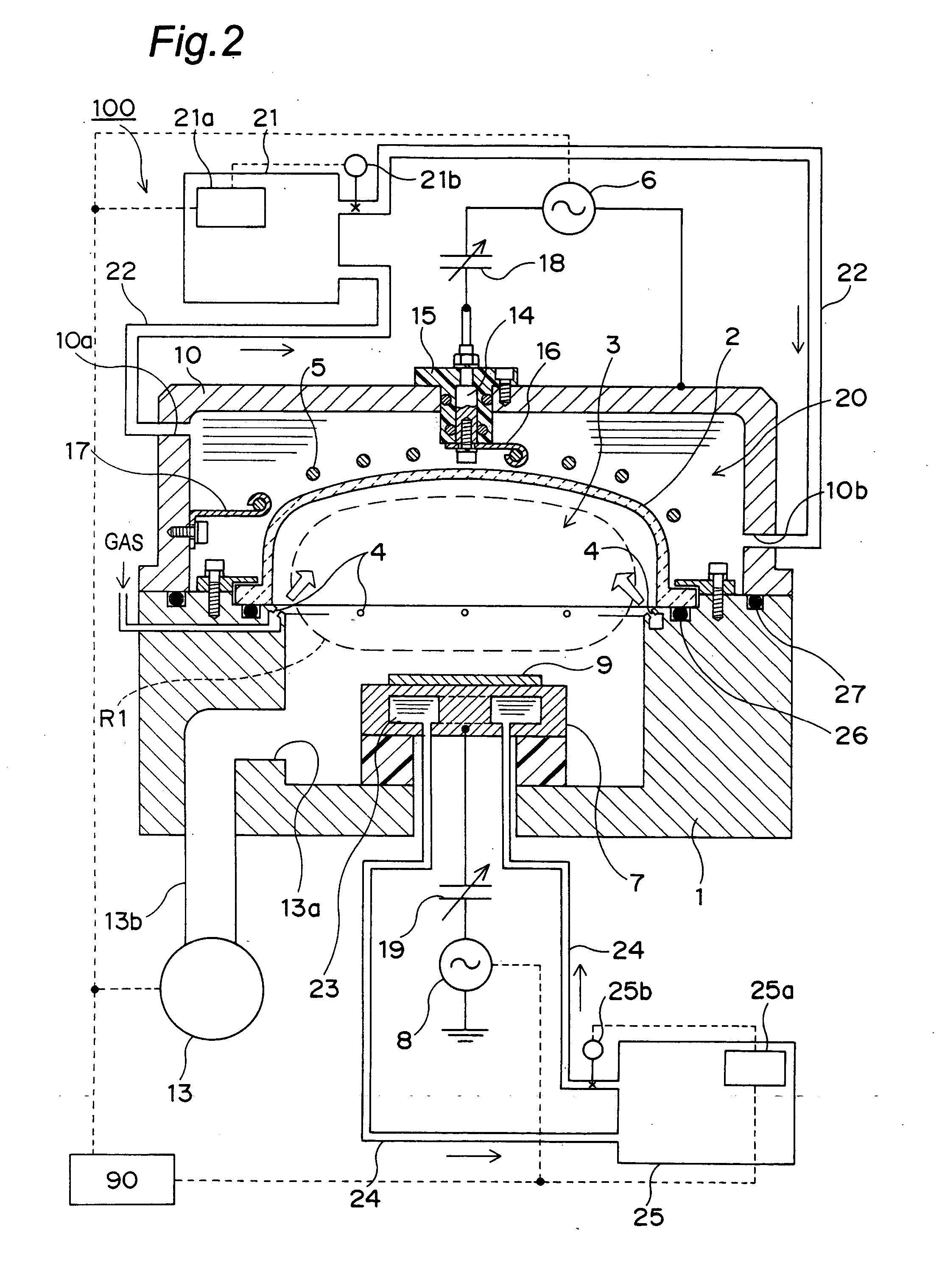

[0116] It is noted here that the present invention is not limited to the foregoing embodiment, and may be carried out in other various aspects. For instance, FIG. 2 shows a schematic sectional view of a plasma processing apparatus 100 which is an example of a plasma processing apparatus according to the second embodiment of the present invention. As shown in FIG. 2, the plasma processing apparatus 100 is different in construction from the plasma processing apparatus 800 of the first embodiment structurally in terms of having not the disc-shaped dielectric window 802 but a generally hemispherical-shell shaped dielectric window 2, but generally similar in construction to the plasma processing apparatus 800 in terms of the other structural components unrelated to the form of the dielectric window 2. The following description is given about this different construction. In addition, for an easier understanding of the description, constituent parts similar to those of the plasma processin...

third embodiment

[0133] Next, FIG. 5 is a schematic sectional view of a plasma processing apparatus 200 according to a third embodiment of the present invention. As shown in FIG. 5, the plasma processing apparatus 200 is different in construction from the plasma processing apparatus 100 of the second embodiment structurally in terms of having not the generally hemispherical-shell shaped dielectric window 2 but a generally plate-shaped dielectric window 202, but similar in construction to the plasma processing apparatus 100 in terms of the other structural components unrelated to the form of the dielectric window 202. Further, as shown in FIG. 5, the plasma processing apparatus 200 is similar in construction to the plasma processing apparatus 800 in terms of having the generally disc-shaped window 202, but different in terms of placing a liquid flow passage 220 and a coil 205 in the inside of the dielectric window 202. This different construction only is explained below. In addition, for an easier un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical resistivity | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Dielectric polarization enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com