Protective hand covering and dispenser apparatus

a hand covering and dispenser technology, applied in the field of hand coverings, can solve the problems of affecting the performance of hand coverings, so as to reduce the time required to perform certain types of procedures, and improve the effect of hand coverings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

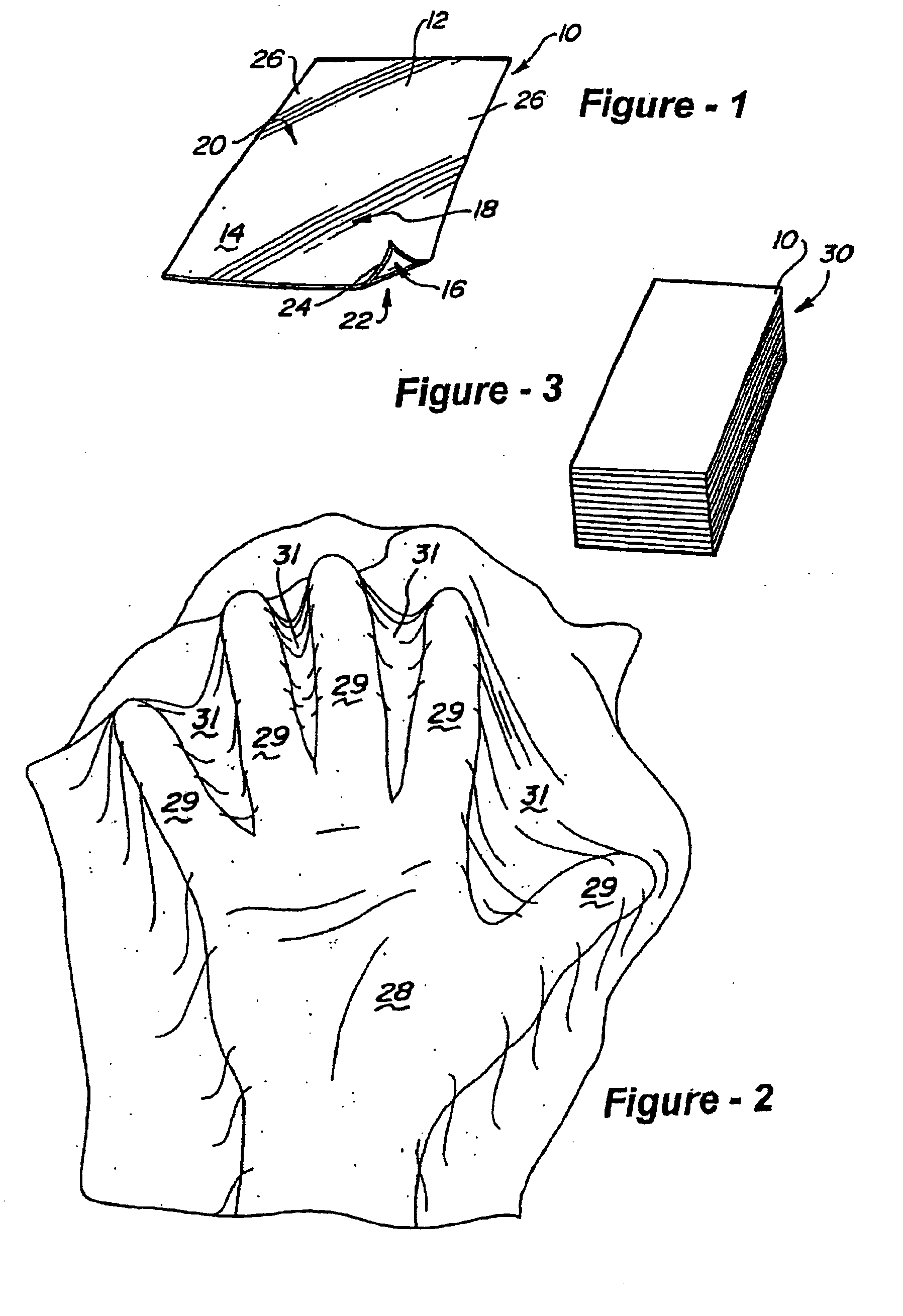

[0025] A rectangular, whole-hand version of the protective hand covering in accordance with this invention is shown in FIG. 1 and is generally designated by reference number 10. The protective hand covering 10 comprises a sheet 12 of thin flexible film 14 which has a front surface 16 and a back surface 18. A pressure-sensitive adhesive 20 is distributed on the back surface 18 of the thin flexible film 14. A corner 22 of protective hand covering 10 is turned up in FIG. 1 to allow the side surface 24 and front surface 16 of the hand covering to be viewed.

[0026] The sheet 12 of thin flexible film 14 is preferably slightly oversized with respect to the portion of the user's hand intended to be covered by the protective hand covering. The oversized edge portions 26 of the sheet 12 are designed to wrap around and adhere to the sides and a portion of the back of the user's hand for reasons further discussed below. In FIG. 1, pressure-sensitive adhesive 20 has been uniformly applied to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com