Sensitivity control for nanotube sensors

a technology of nanotube sensors and sensitivity control, applied in the field of nanotube sensors, can solve the problems of nanotube sensors exhibiting a fast response and a substantially slower recovery, metal contacts to silicon can be sensitive and problematic, and achieve the effect of reducing cross-sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

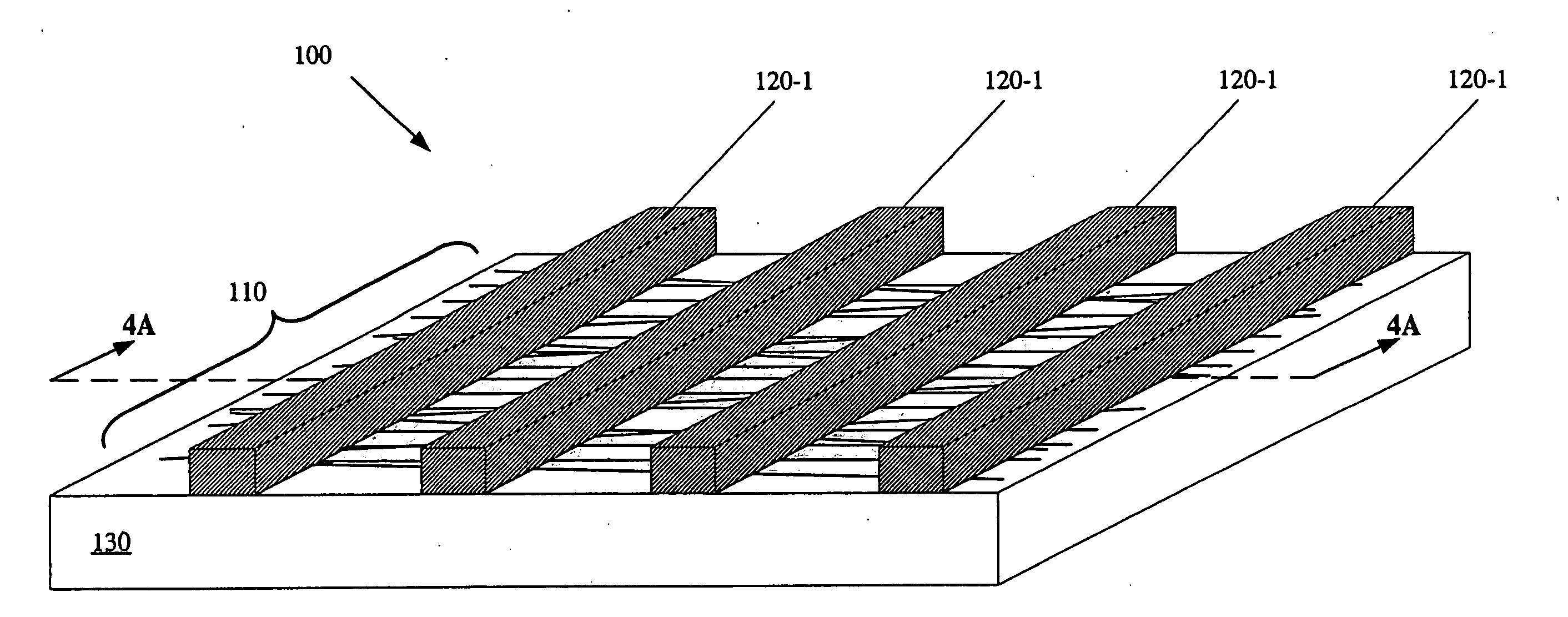

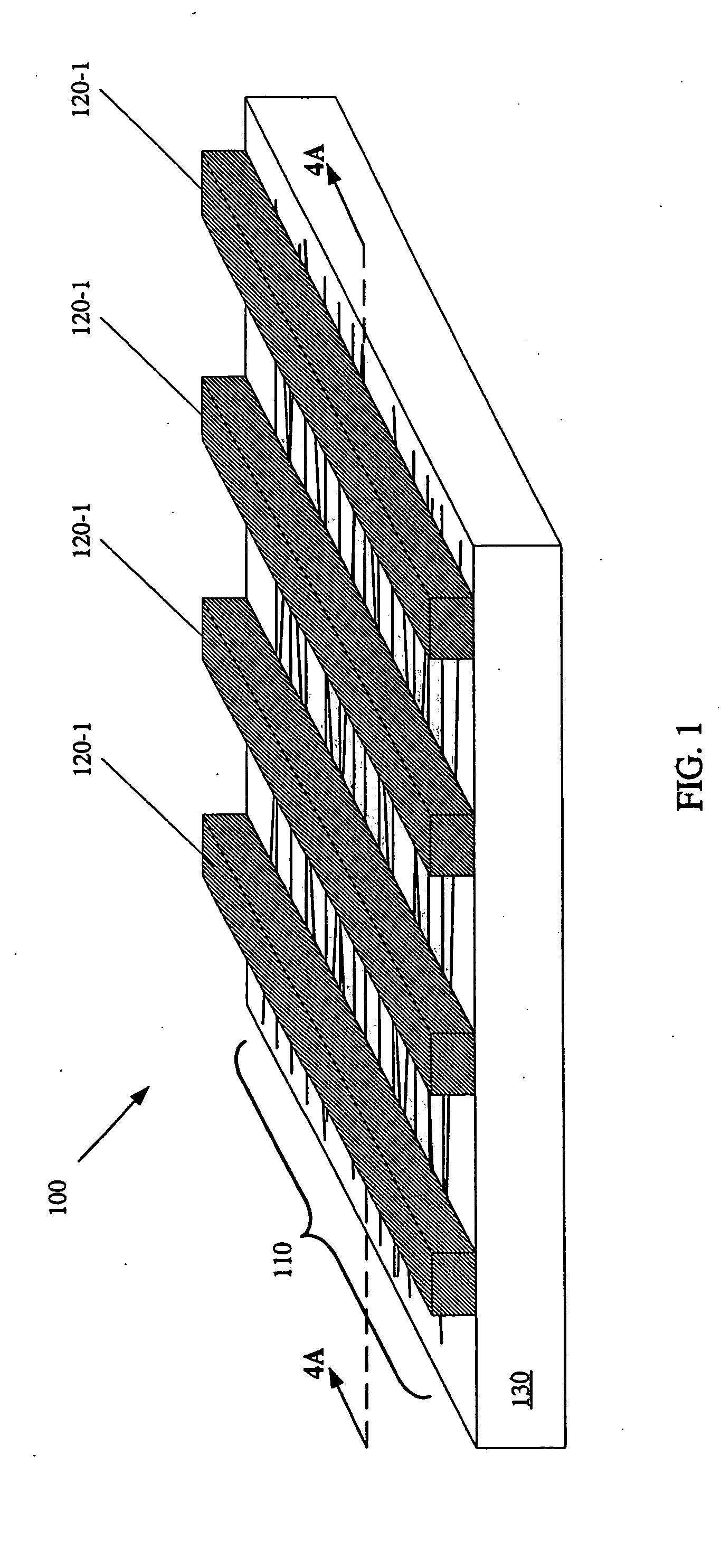

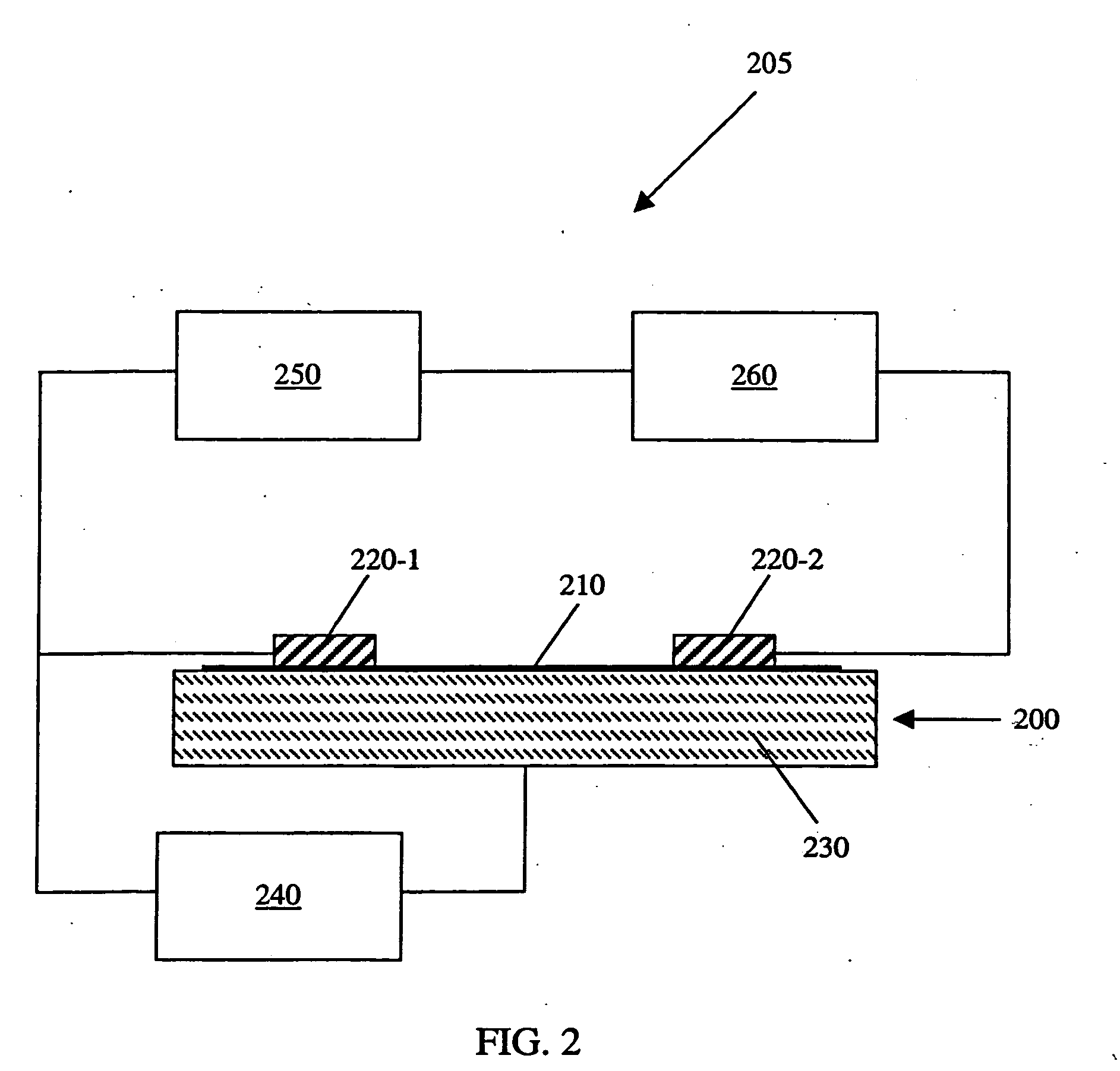

[0038] Carbon nanotubes are usually hollow, elongated structures a few atoms in width with a structure like a sheet of graphite formed into a generally cylindrical configuration. Carbon nanotubes are long molecules, with length to width ratios as large as several thousand or more. They can be formed in furnaces from carbon-containing gases. Carbon nanotubes can form with a single wall, containing just one layer of carbon atoms and having a diameter of one to several nanometers. They can also form with multiple walls, containing a number of hollow cylinders of carbon atoms nested inside one another. They take their name from the nanometer, which is a convenient length for specifying molecular dimensions.

[0039] Other elongated nanostructures have also been developed and named by various researchers. These include nanowires, nanofibers, nanorods, and other structures. Nanostructures having an approximately linear form can be arranged in bundles of structures, such as ropes, braids or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com