Nitride semiconductor devices and method of their manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

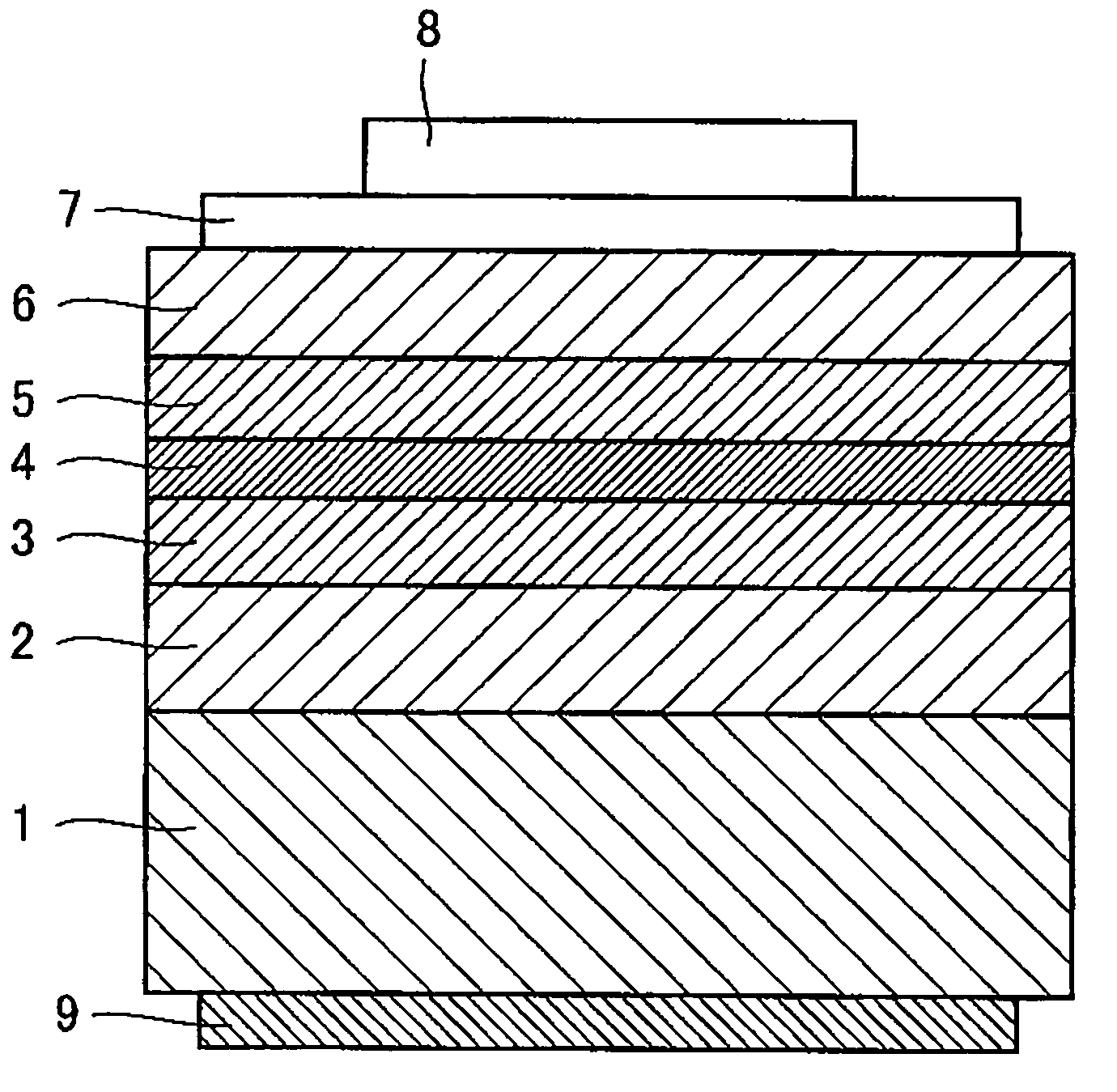

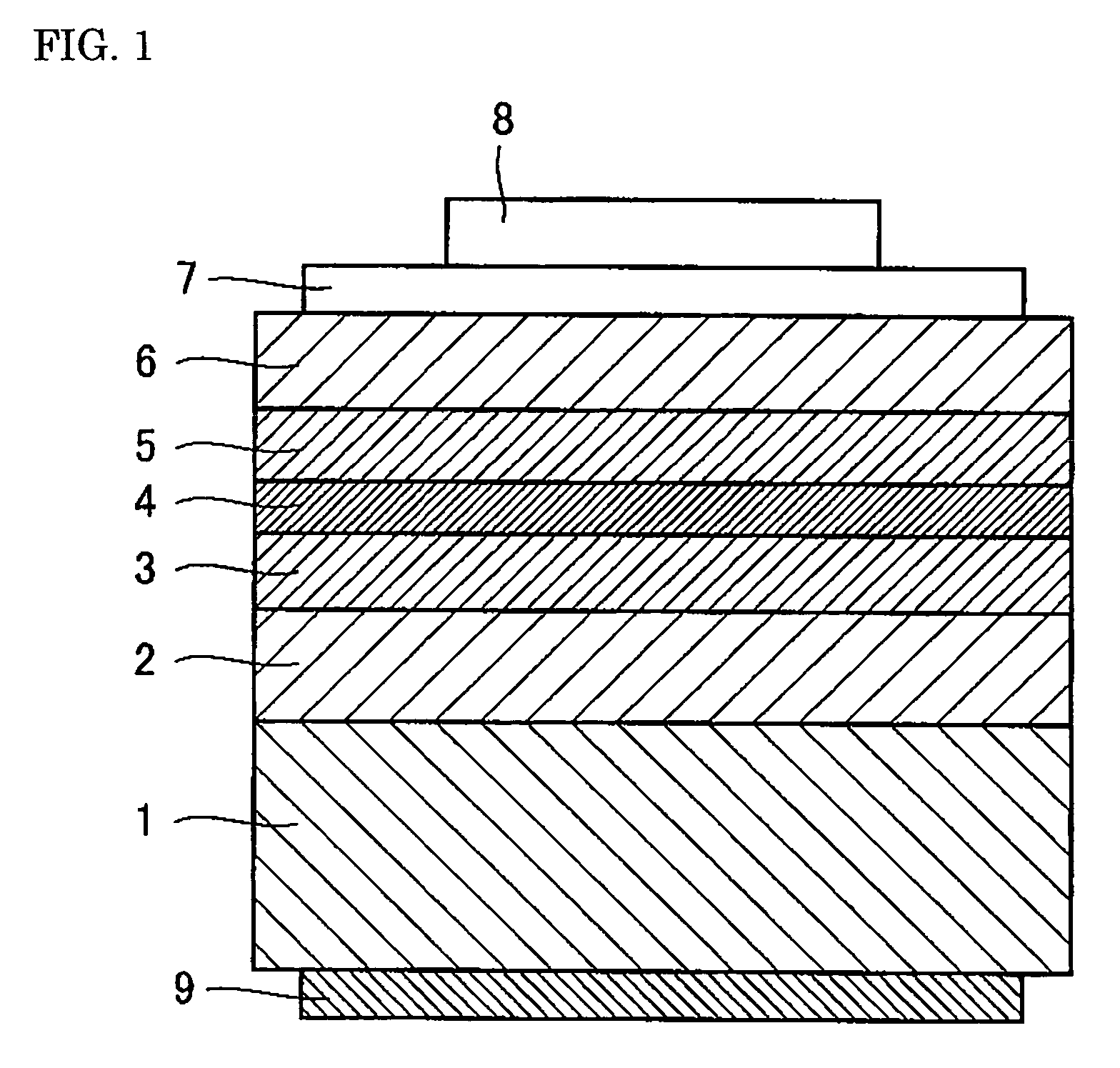

Image

Examples

Example

[0051] Comparative example: 1150° C.

[0052] Pretreating time—10 minutes

Film-Deposition Conditions

[0053] Nitrogen: 20 slm

[0054] Hydrogen: 15 slm

[0055] Ammonia: 5 slm

[0056] TMG: 19 sccm

[0057] Substrate temperature—1150° C.

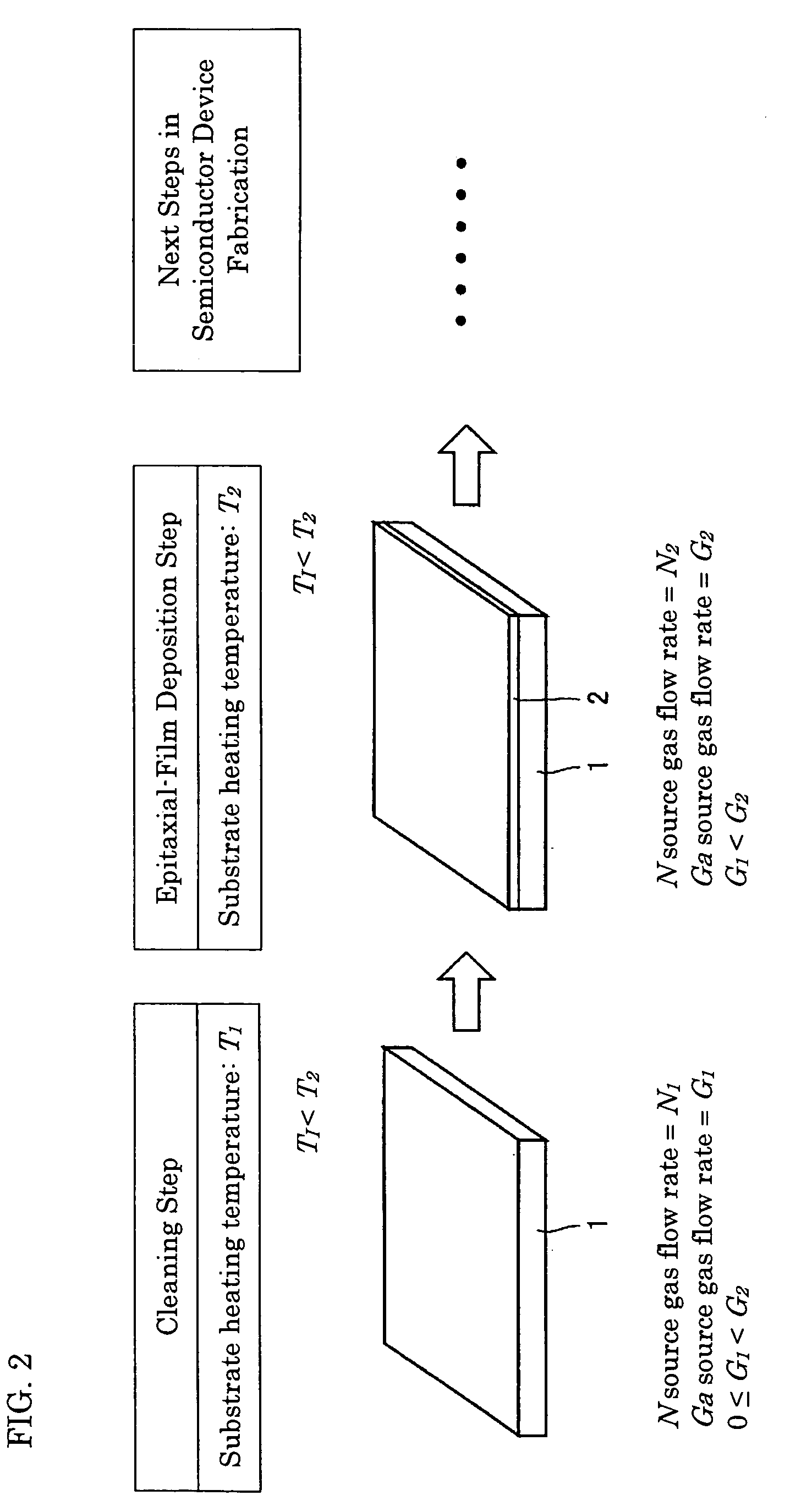

[0058] Utilized as the GaN substrate was a bulk crystal prepared by growing a thick GaN film onto a GaAs substrate with SiO2 made the mask and thereafter removing the GaAs substrate. (Cf. PCT Gazette Pub. No. WO99 / 23693.) In the pretreatment, the Ga source gas TMG was omitted, and ammonia as the nitrogen source gas, and nitrogen and hydrogen as the carrier gases alone were flowed according to the same flow parameters as those in the film-deposition conditions noted above. The root-mean-square (RMS) roughness of the substrate after having undergone the pretreatment was assessed using atomic force microscopy (AFM).

[0059]FIG. 3 is micrographs made using AFM, showing 10 μm×10 μm of roughness, for RMS calculations, along the front side of the GaN substrate. The v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com