Attic ventilation system

a ventilation system and attic technology, applied in ventilation systems, lighting and heating apparatus, heating types, etc., can solve the problems of inconvenient living conditions, inconvenient installation, and ineffective insulation in preventing the flow of heated air from the attic, so as to reduce the complexity of attic installation, time and cost, and the effect of less expensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

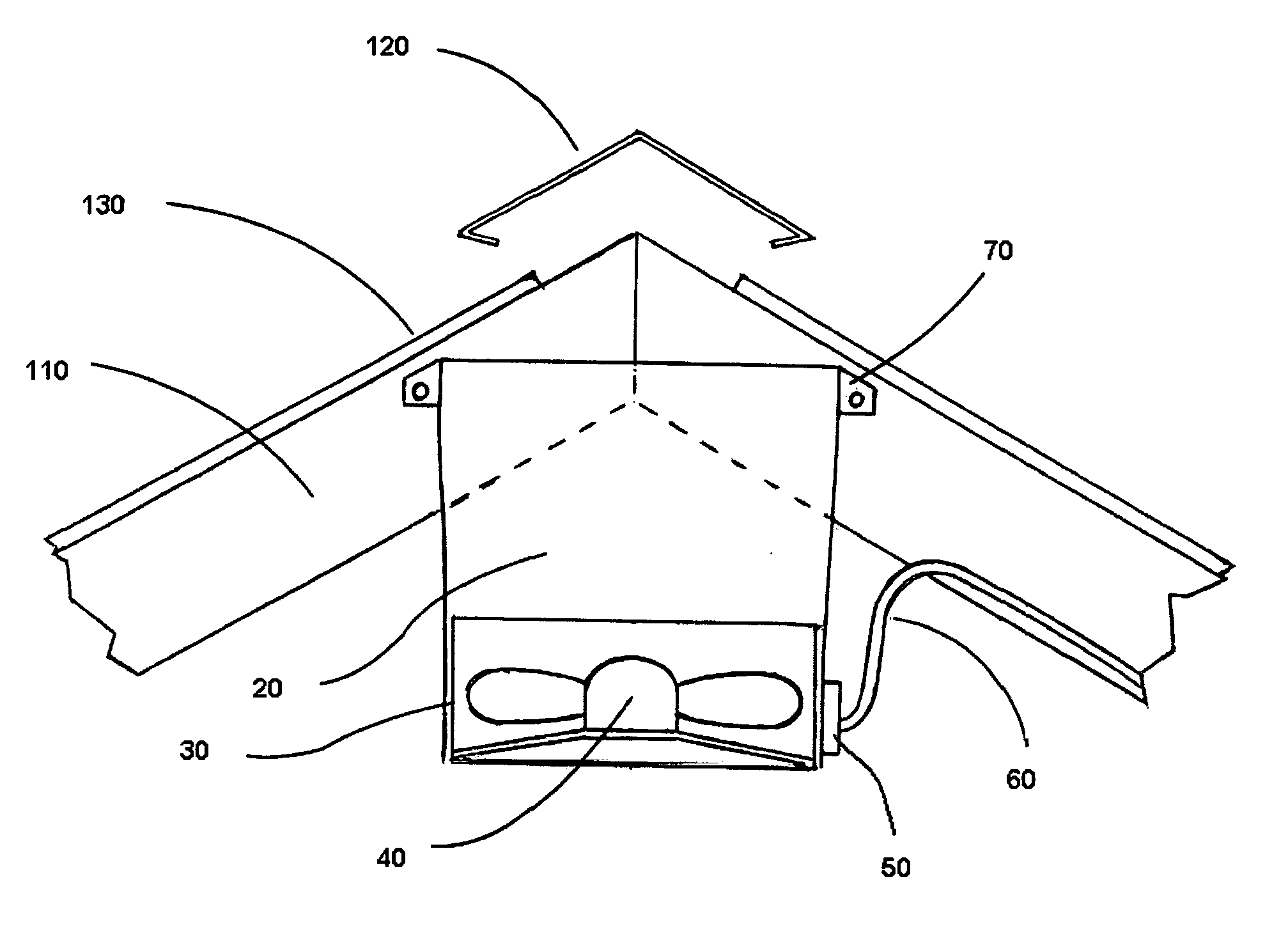

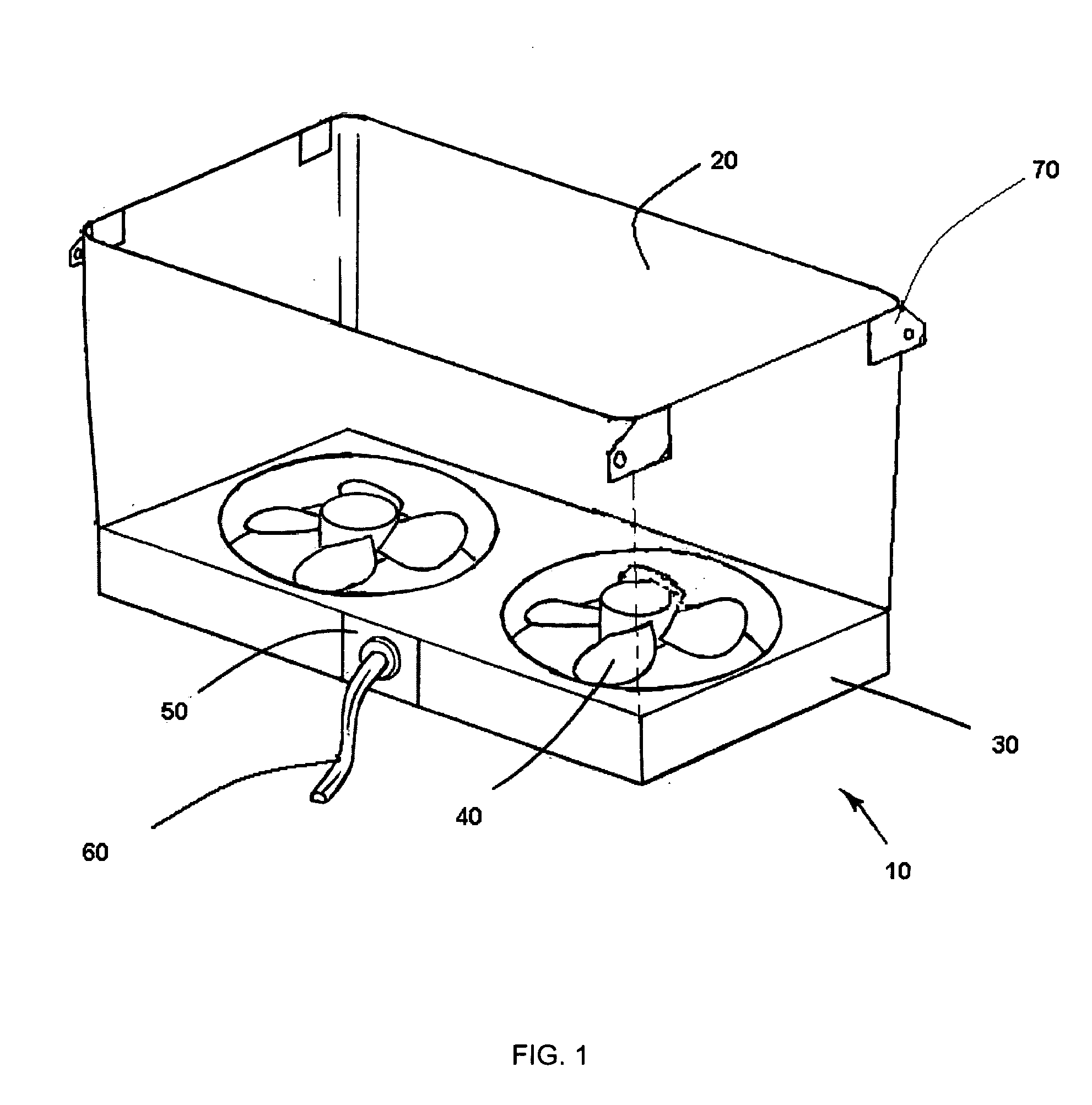

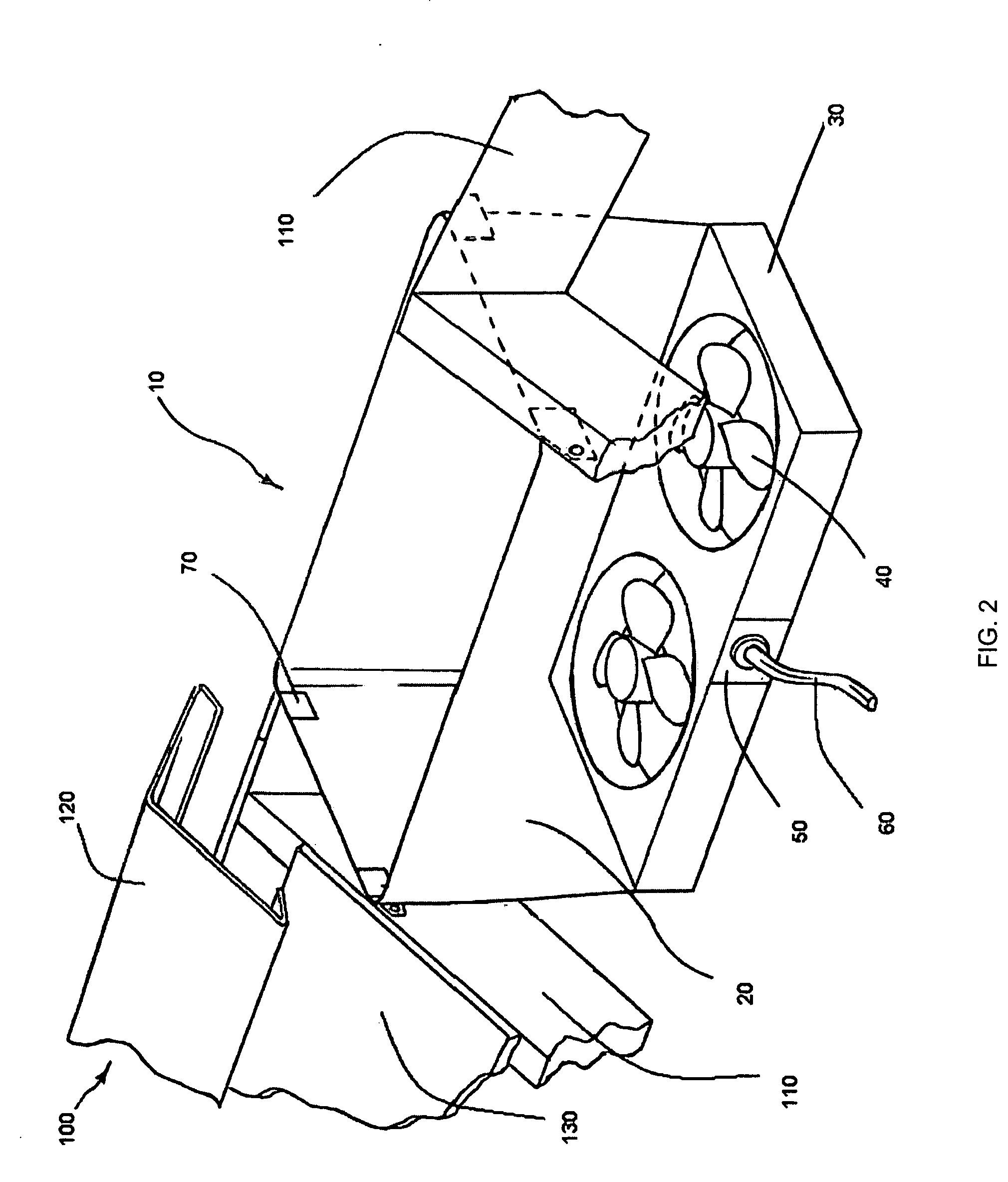

[0019]FIGS. 1-3 illustrate a ventilation system according to an embodiment of the invention. As shown, the system 10 may include an air sealer 20 coupled to a fan housing 30 (also called a flow generator). The air sealer 20 includes a structure operable to direct air toward a vent located in the roof of a building. Specifically, as shown in FIG. 1, the air sealer 20 may comprise a duct having open top and bottom ends. The air sealer 20 may be connected to the fan housing 30 such that a substantially fluid (air) tight seal is formed. Preferably, the air sealer 20 comprises flexible material to enable the sealer 20 to fit between variably spaced rafters (e.g., the flexible material may be contorted to fit a given space). By way of specific example, the material comprising the air sealer 20 may include flexible non-woven and woven material (e.g., canvas) attached to the perimeter of the fan housing 30.

[0020] The fan housing 30 may include one or more exhaust fans 40 configured to draw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com