System for monitoring the temperature of wheel bearings in railroad cars

a technology for wheel bearings and temperature monitoring, which is applied in the direction of railway signalling, railway signalling and safety, railway profile gauges, etc., can solve the problems of false response of ir radiation sources, poor sensitivity of ir detectors, etc., and achieve poor sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

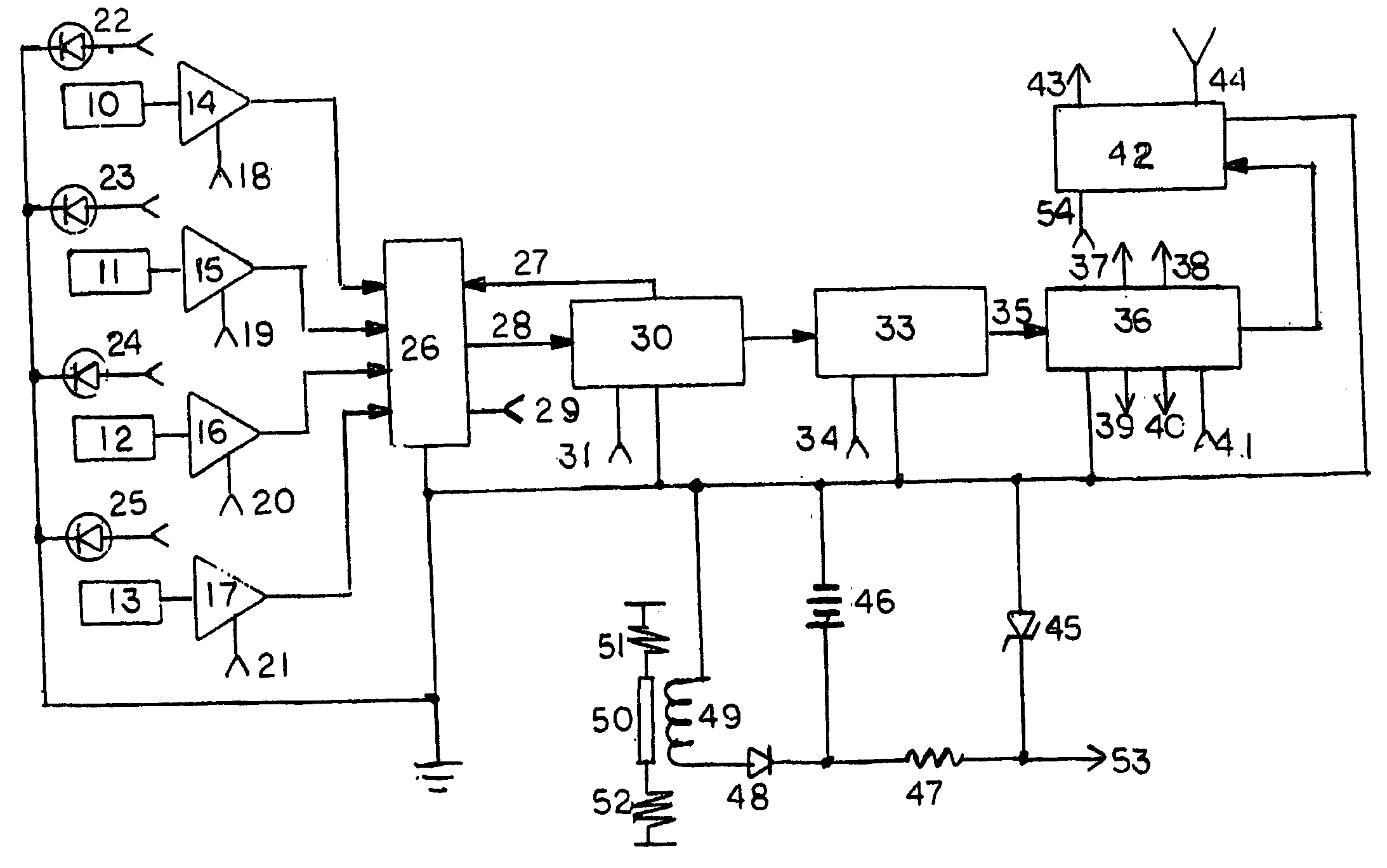

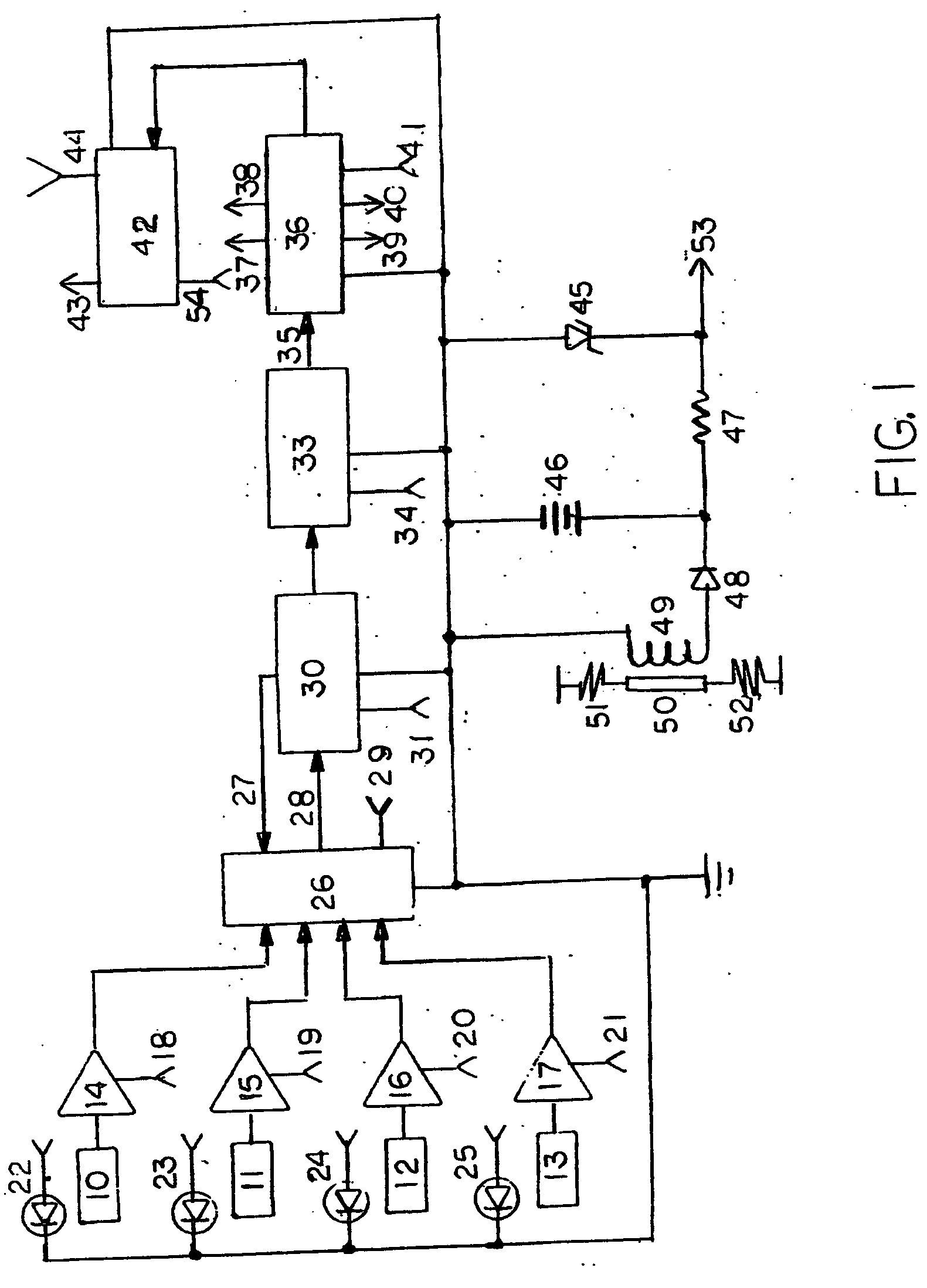

[0012] With reference to FIG. 1, temperature sensors 10, 11, 12, and 13 are installed in close proximity to the bearings of each of the wheels of a railroad car or carriage. Railroad cars usually have four axles and eight wheels, however, only the sensors for four wheels are shown; the sensors for all eight wheels are identical. The sensors generate electrical signals analog to the temperature of these bearings. The signals are amplified by the amplifiers 14, 15, 16, and 17 and passed on to a multiplexer module 26, which contains a solid state switching circuit that continuously cycles, serially selecting inputs from amplifiers 14, 15, 16, and 17 and directing the signals from these inputs to the output 28. The cycling is controlled by the clock signals from the module 30 via line 27.

[0013] Module 30 is an A / D converter that converts the signals analog to the bearing temperature into digital data. Module 30 also contains a digital clock and a circuit for imparting a string of code ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com