Tailpipe of automotive vehicle

a tailpipe and automotive technology, applied in the direction of machines/engines, mechanical equipment, gas passages, etc., can solve the problems of not being able to readily mount at the exhaust pipe, the backflow of exhaust into the engine, and noise serious, so as to reduce the length, reduce noise, and be easy to mount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

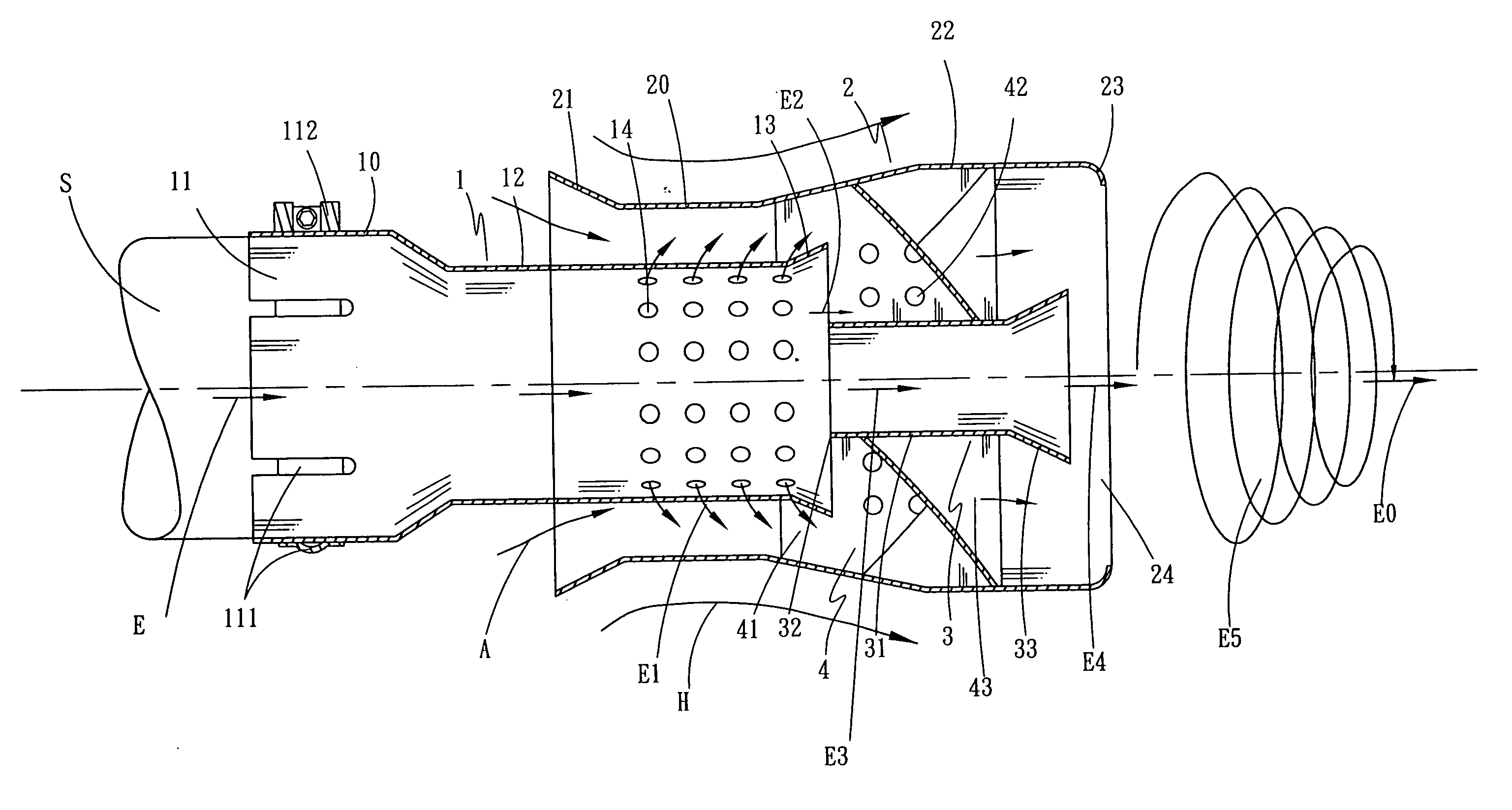

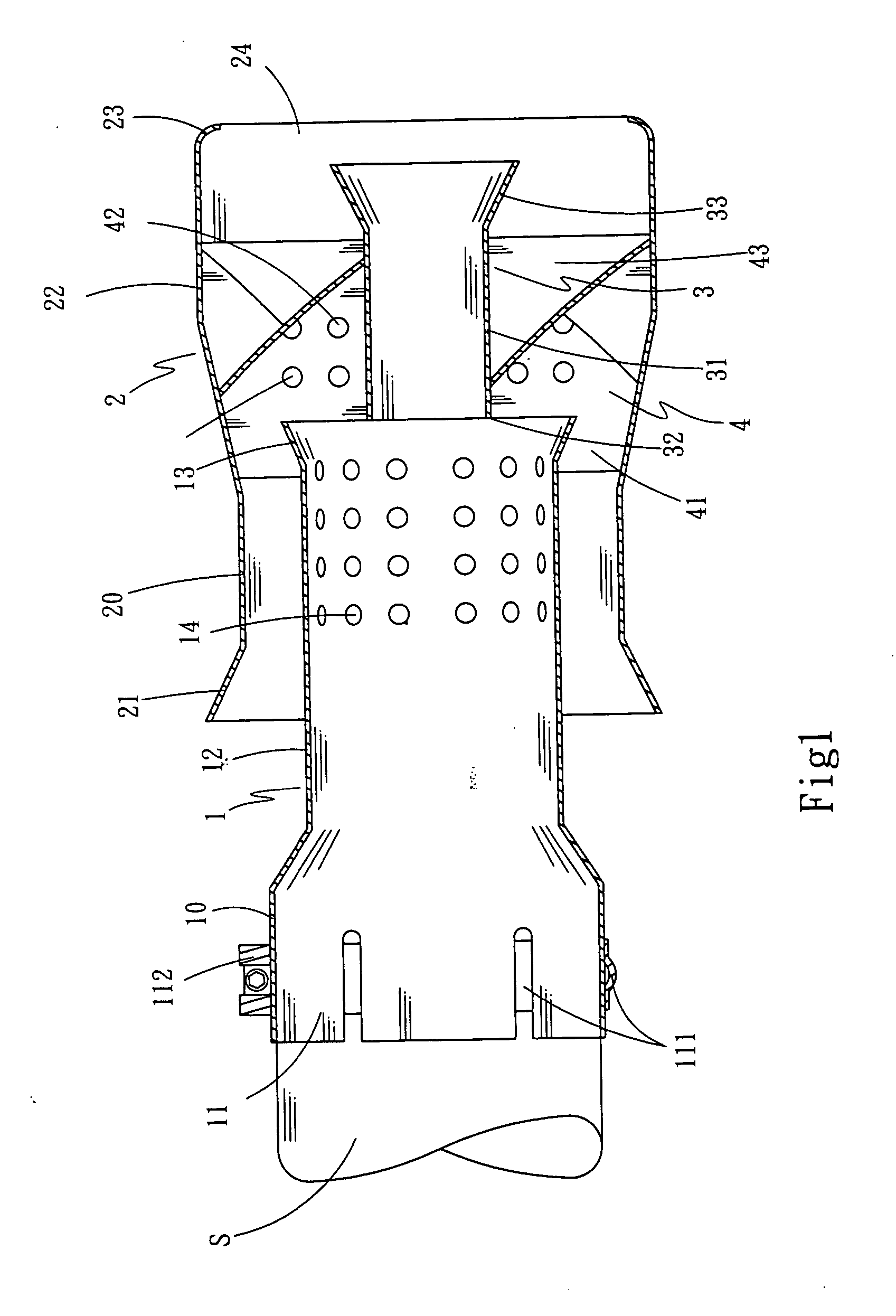

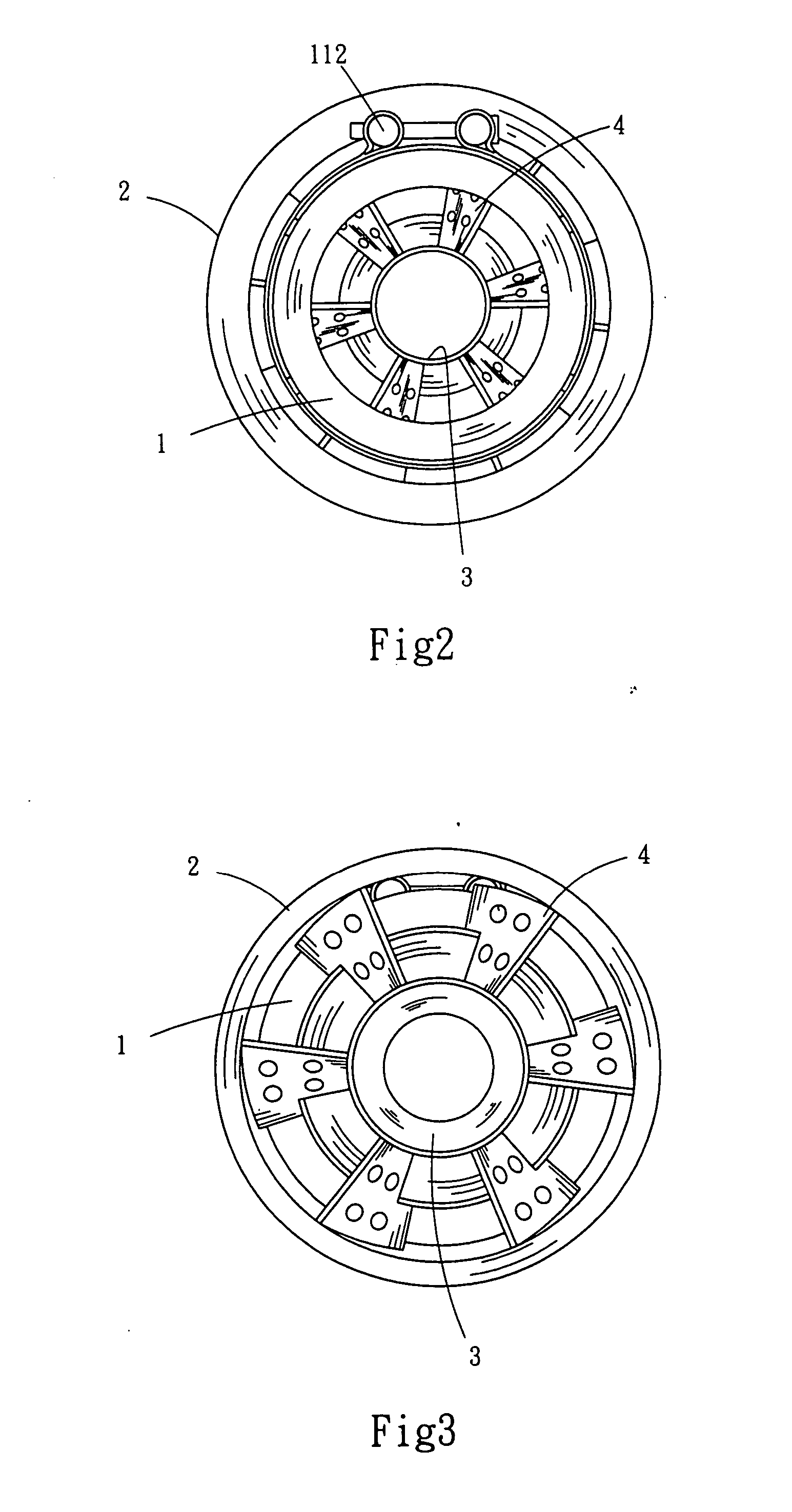

[0015] Referring to FIGS. 1 to 4, there is shown a tailpipe of an automotive vehicle constructed in accordance with the invention. The tailpipe comprises a front tube 1, an outer tube 2, a rear tube 3, and a plurality of twisted blades 4. Each component will be described in detail below.

[0016] The front tube 1 comprises a front section 10, a coupling 11 at the front section 10, the coupling 11 having a plurality of lengthwise slits 111 and a ring fastener 112 enclosed the coupling 11 for flexibly compressing the coupling 11 and fastening one end of a muffler S at the coupling 11, a flared rear section 13, and a neck 12 interconnected the front section 10 and the rear section 13, the neck 12 having a plurality of rows of apertures 14 on its surface.

[0017] The rear tube 3 comprises a front section 32 coupled to the rear section 13, an intermediate section 31 having a diameter slightly smaller than that of the front tube 1, and a flared rear section 33.

[0018] A rear portion of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com