Fixed slope vacuum boring and mud recovery container

a vacuum boring and mud recovery technology, applied in the direction of cleaning filter means, cleaning equipment, borehole/well accessories, etc., to achieve the effect of reducing floor space, concentrating weight, and facilitating interaction and plumbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

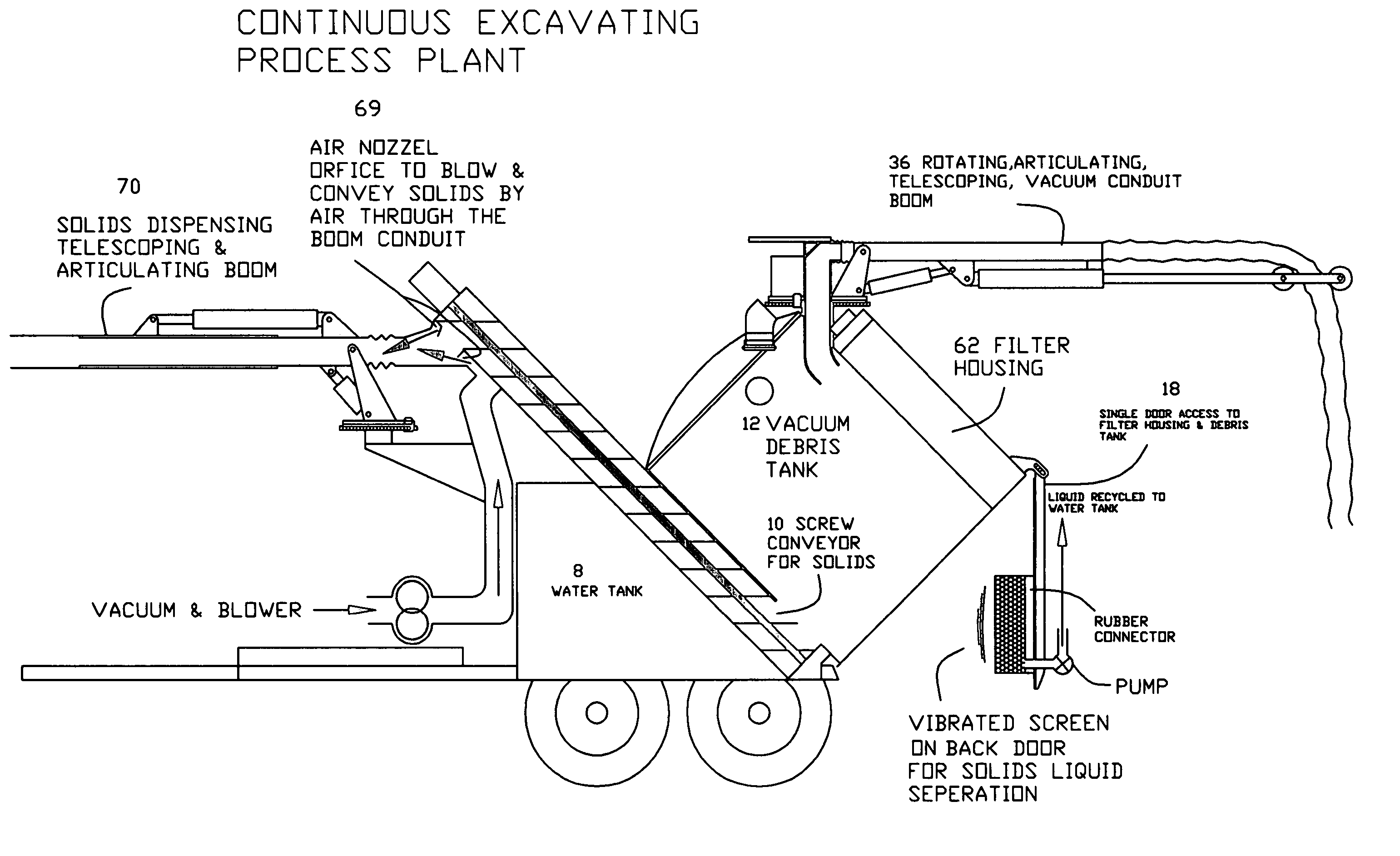

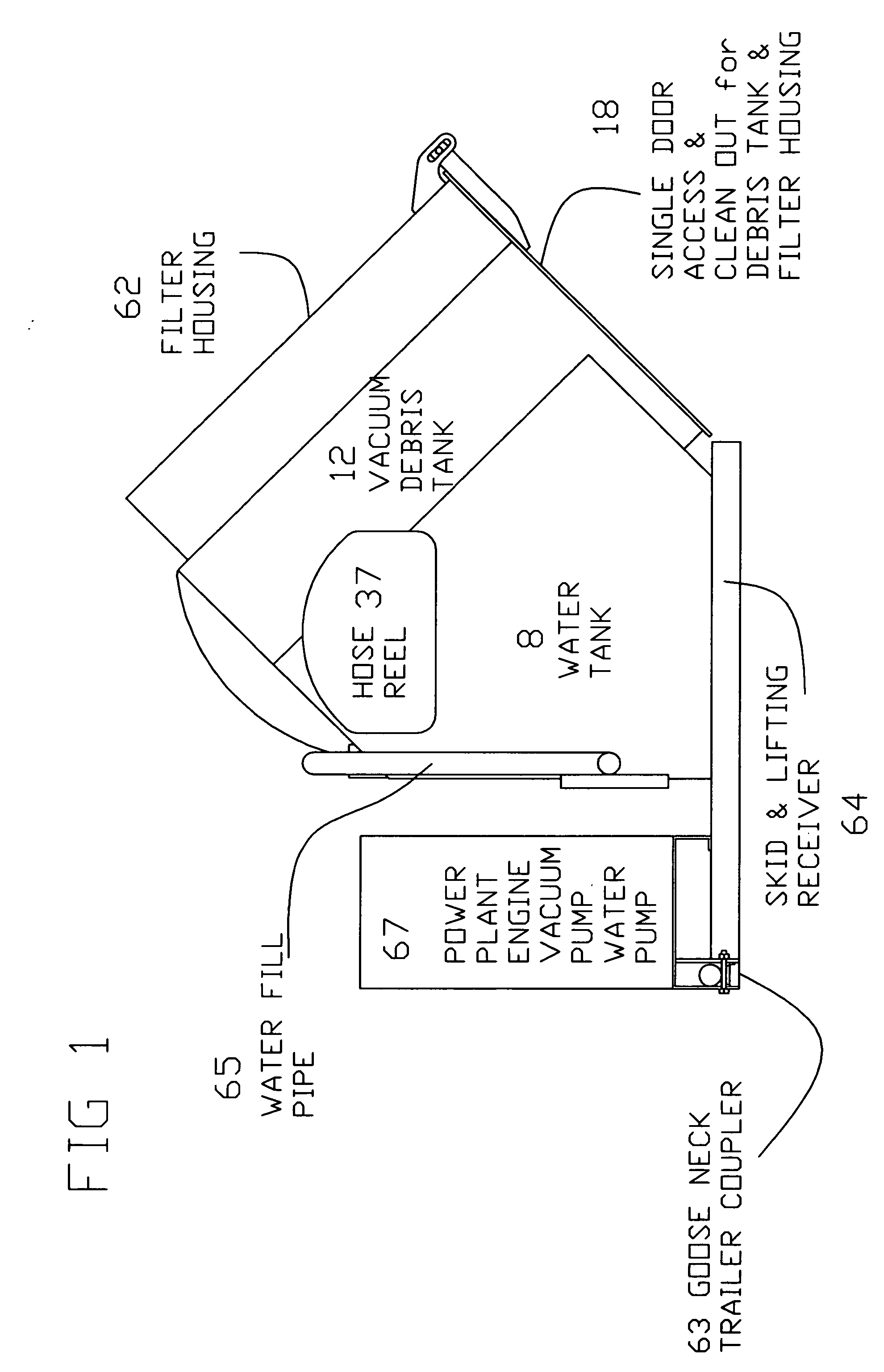

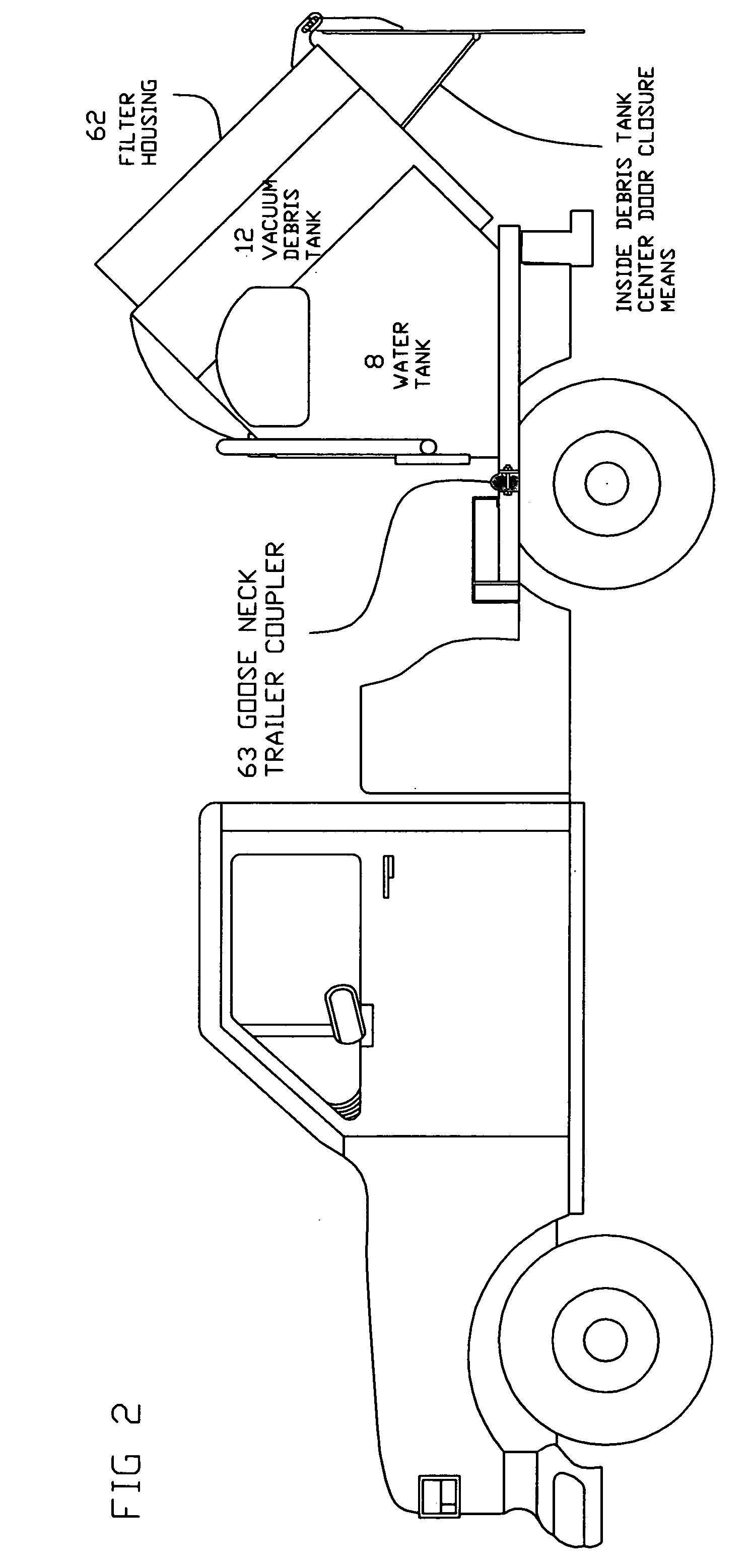

[0043] Referring to FIG. 1, a vacuum container (12) is mounted at a fixed slope and supported by a liquid water container (8). The fixed slope may be of sufficient angle to allow debris to empty by gravity when the access door (18) is opened. This arrangement creates a compact package unit, reduces floor space needed to contain both liquid container (8) and vacuum debris container (12) and condenses the weight of the water container (8) and vacuum debris container (12) combination. The dual container combination lends itself, by compactness, to use as a multifunctional convertible unit capable of being quickly converted from a skid mount unit (64) to a trailer mount unit, to a gooseneck hitch coupled (63) pick up truck bed unit, to a fork lift or skid steer transported unit. A filter housing (62) may be mounted piggyback onto the outer shell of the vacuum debris container (12) thus further compacting the space required for the system and again condensing weight and increasing the ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com