Glass substrate package

a glass substrate and package technology, applied in the field of packaging, can solve the problems of limiting the efficiency of transportation and storage of glass substrates, the inability to eliminate the dirtying of the edge faces of each glass substrate in that method, and the inability to reduce the time and cost required for the washing process, and achieves the effect of eliminating scratches and dirt, high transportation efficiency, and reducing the time and cost of the washing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Now, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

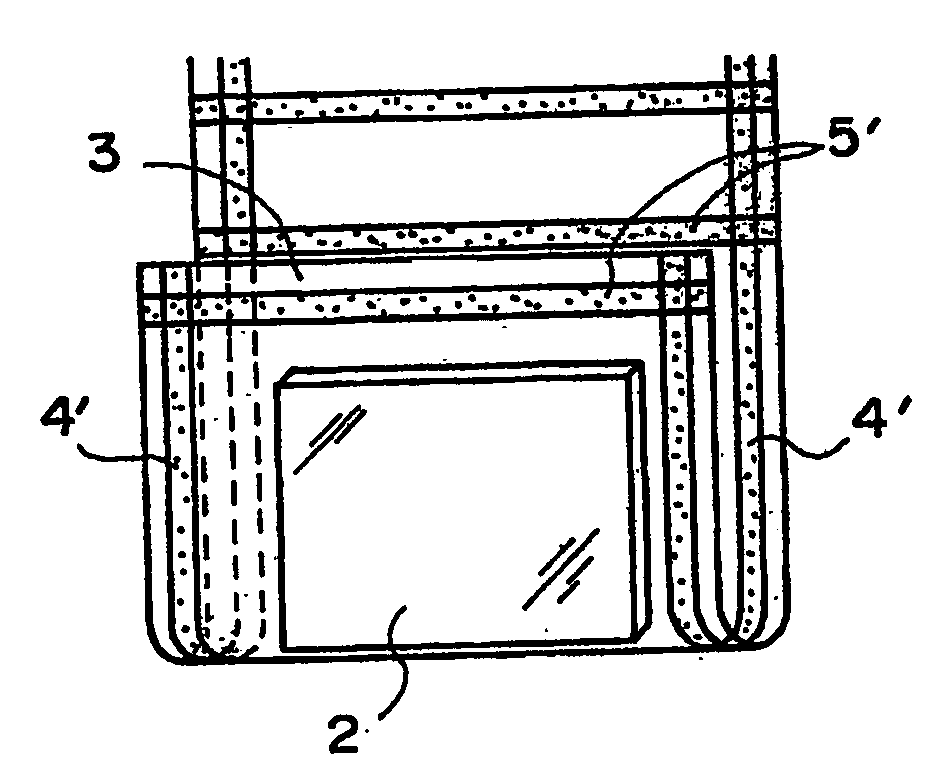

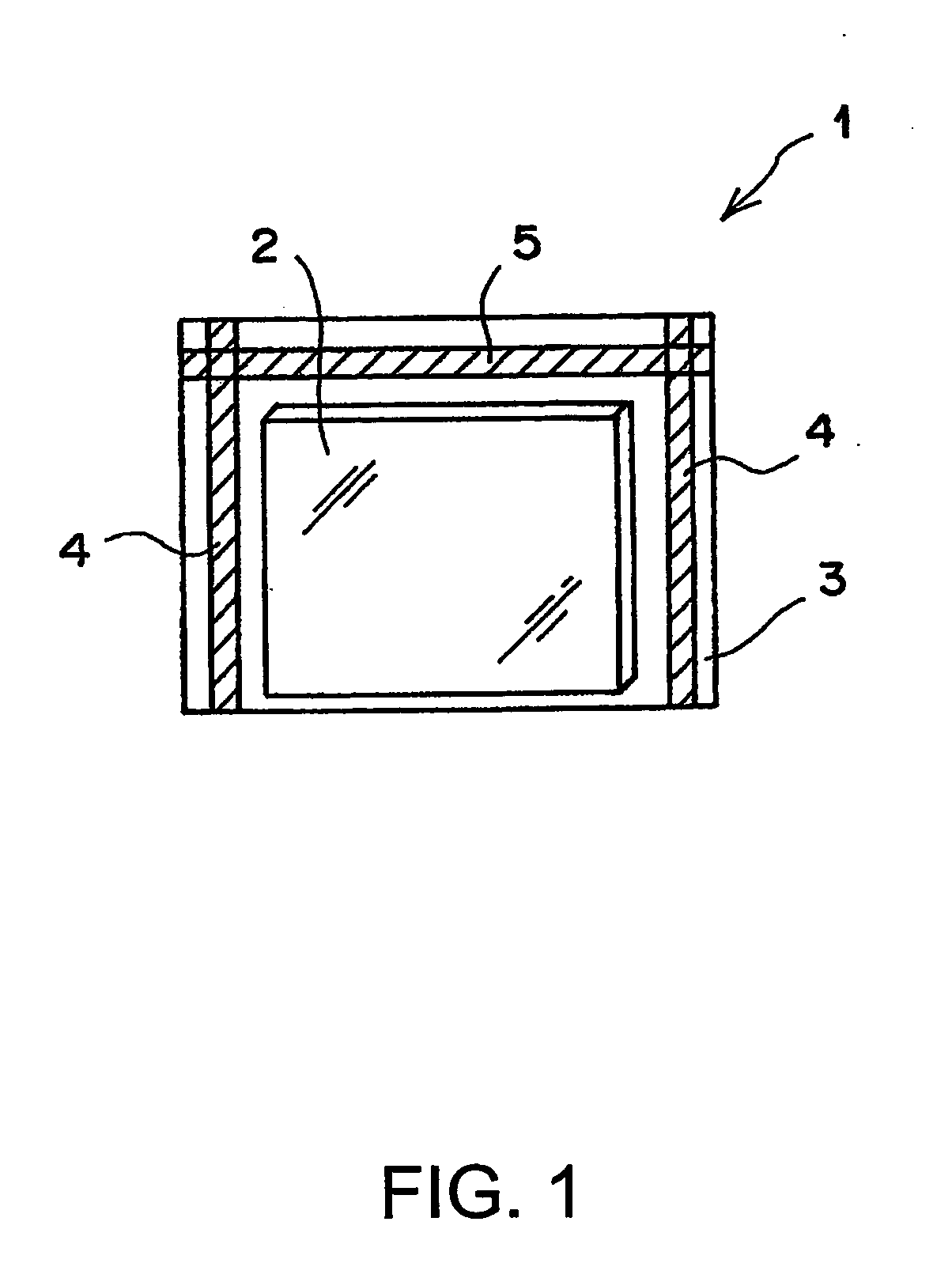

[0028] Shown in FIG. 1 is a glass substrate package 1 according to one embodiment of the present invention. In the glass substrate package 1, a glass substrate 2 is packed and sealed with a polyethylene terephthalate film 3 (hereinafter, referred to as the “PET film 3”). In FIG. 1, the PET film 3 is folded at the bottom edge of the glass substrate package 1. Provided near the right and left edges and the upper edge of the glass substrate package 1 are heat-sealed portions 4 and 5, respectively. It is desirable that the internal volume of the glass substrate package 1 has been deaerated.

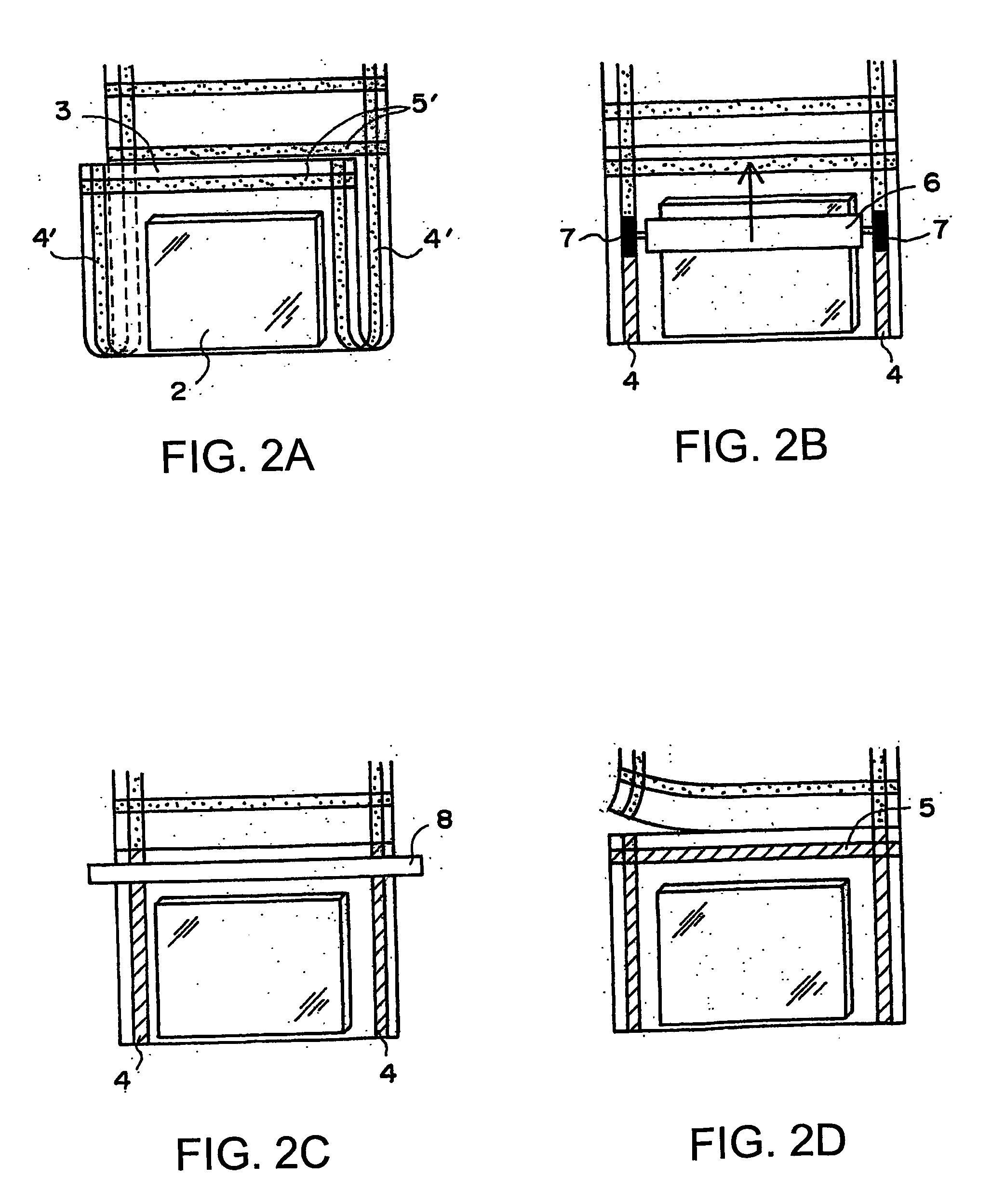

[0029]FIG. 2 shows individual steps of an exemplary process for preparing the glass substrate package 1 shown in FIG. 1.

[0030] First, in the step of FIG. 2A, the glass substrate 2 is inserted into a folded end of the PET film 3 in a long and continuous form. Herein, a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| internal volume | aaaaa | aaaaa |

| friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com