Fluid pump apparatus

a pump and fluid technology, applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problem that the total fan noise in the audible frequency band of human beings cannot be reduced, and achieve the effect of reducing the pressure variation of fluid, reducing the fan noise (wind noise), and cross-sectional area of the vortex flow chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

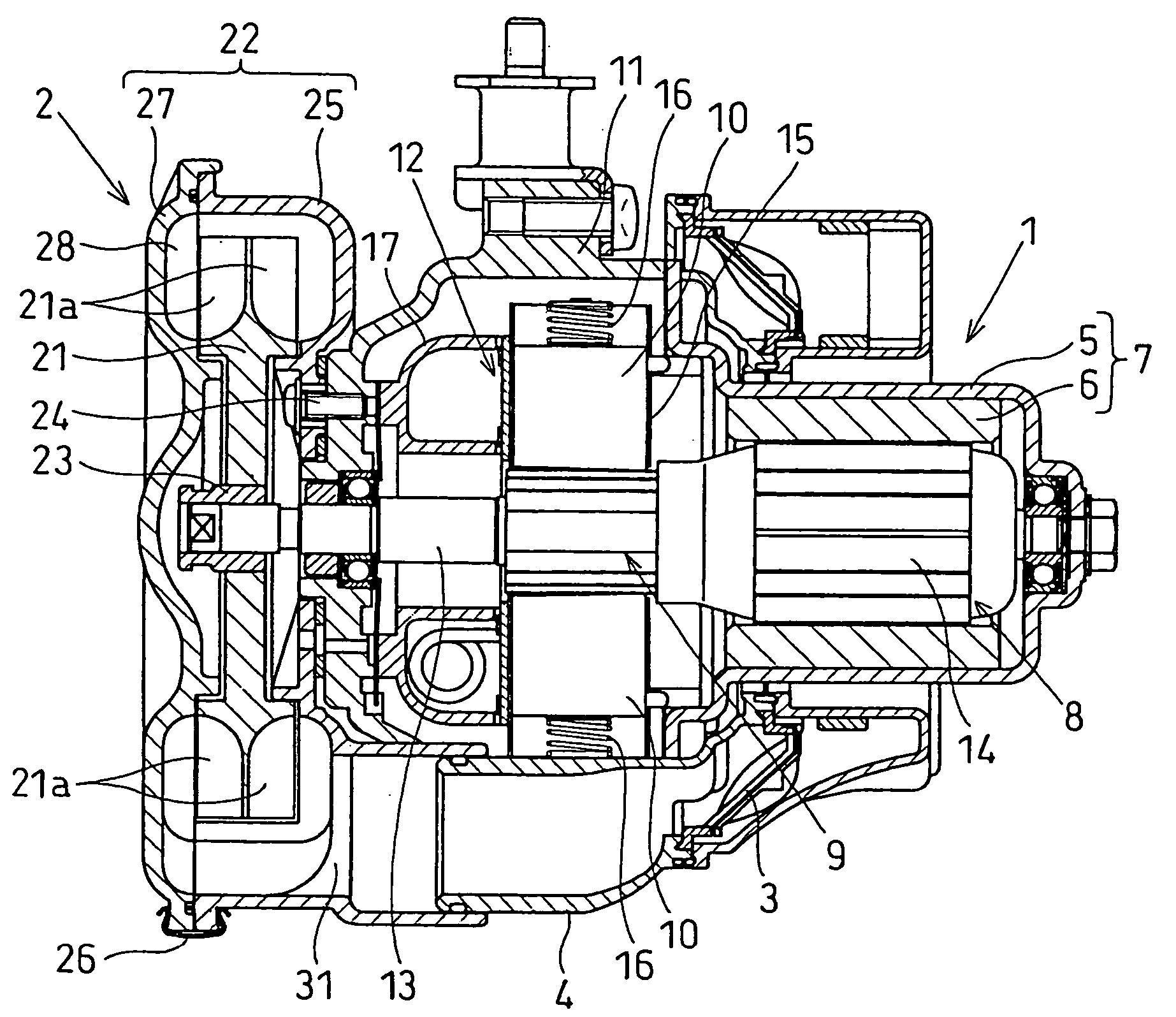

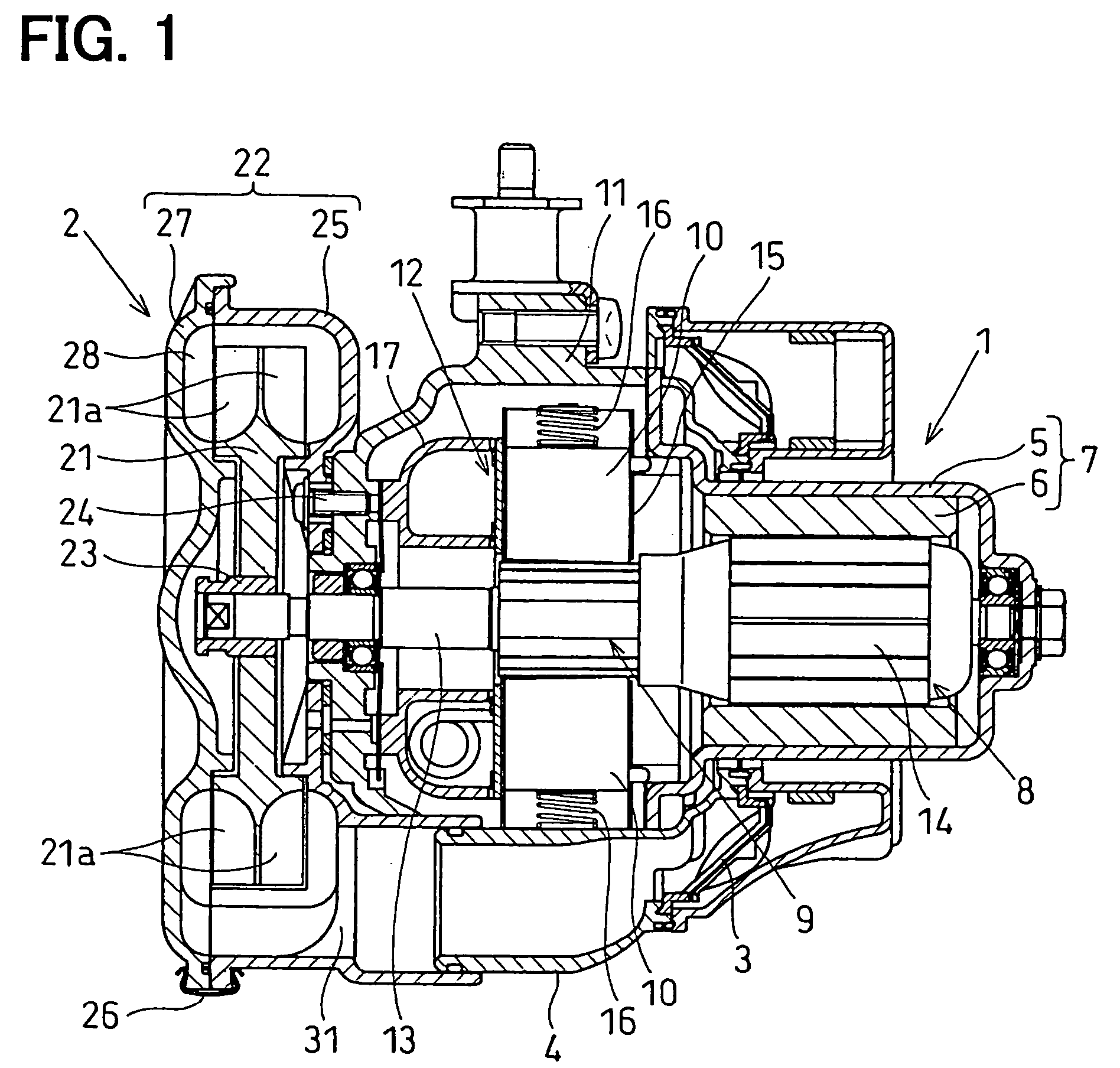

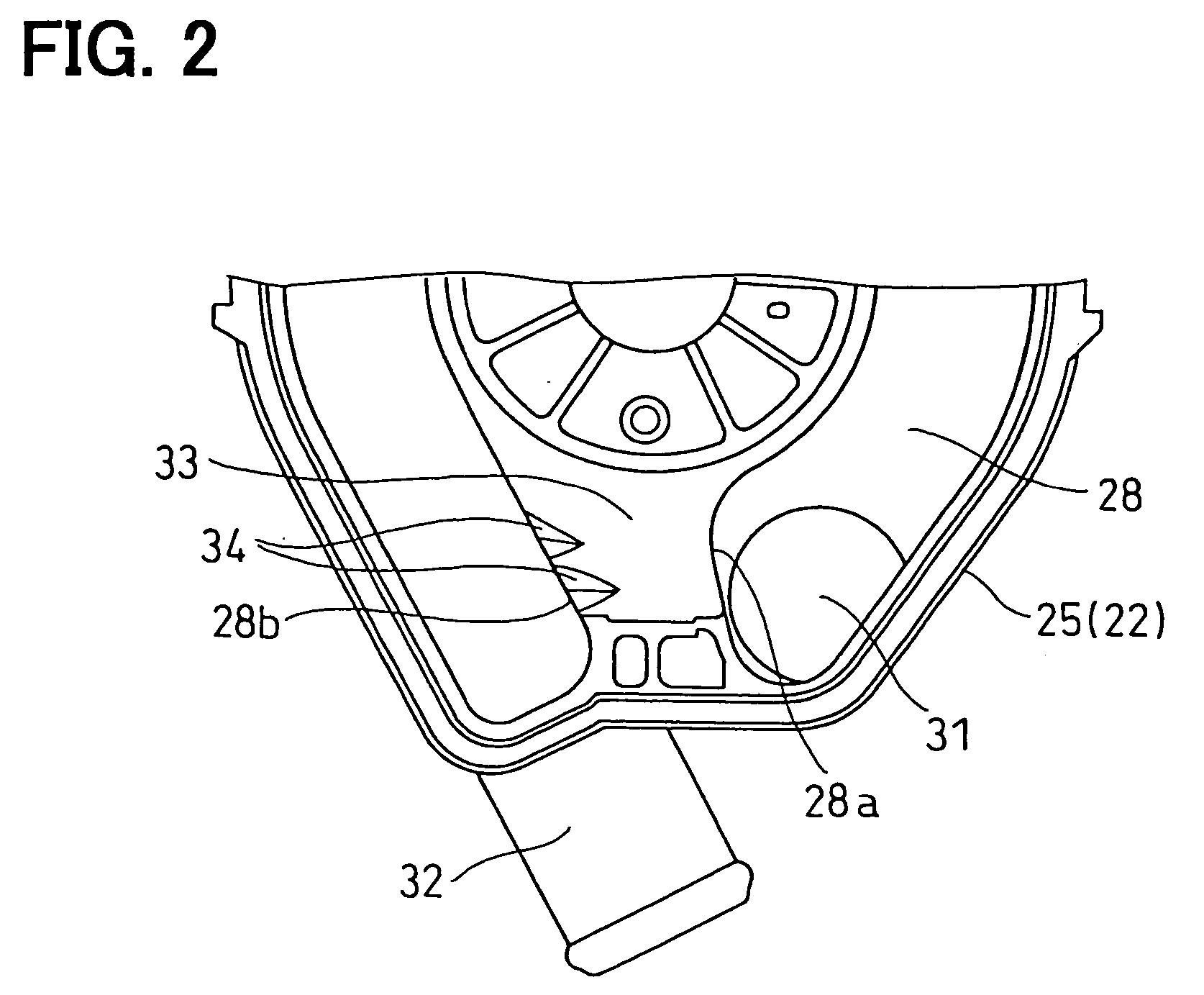

[0023] The present invention will be explained below with reference to the embodiment, in which the present invention is applied to an electrical air supply pump, as shown in FIGS. 1 to 3.

[0024] The air supply pump compresses air and pumps out the compressed air. The air supply pump is used, for example, in a secondary air supply system for an automotive engine, wherein the air supply pump supplies the compressed air into an exhaust pipe of the engine at an upstream side of a catalyst for purifying the exhaust gas.

[0025] The air supply pump, which comprises a blower device having a double-blade and vortex flow type impeller, is shown as an example in the first embodiment.

[0026] The air supply pump, as shown in FIG. 1, comprises an electric motor 1, the above mentioned blower device 2, and an air duct portion 4 in which a filter 3 is arranged.

[0027] The electric motor 1 of this embodiment is a DC motor, which comprises a stator 7 having a cylindrical yoke 5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com