Micro scale flow through sorbent plate collection device

a micro-scale flow and collection device technology, applied in the field of analyte collection, can solve the problems of compromising the dynamic range, requiring higher power consumption, and requiring high pressure drop associated with this sort of device, and achieving the effect of reducing the cost of analyte collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

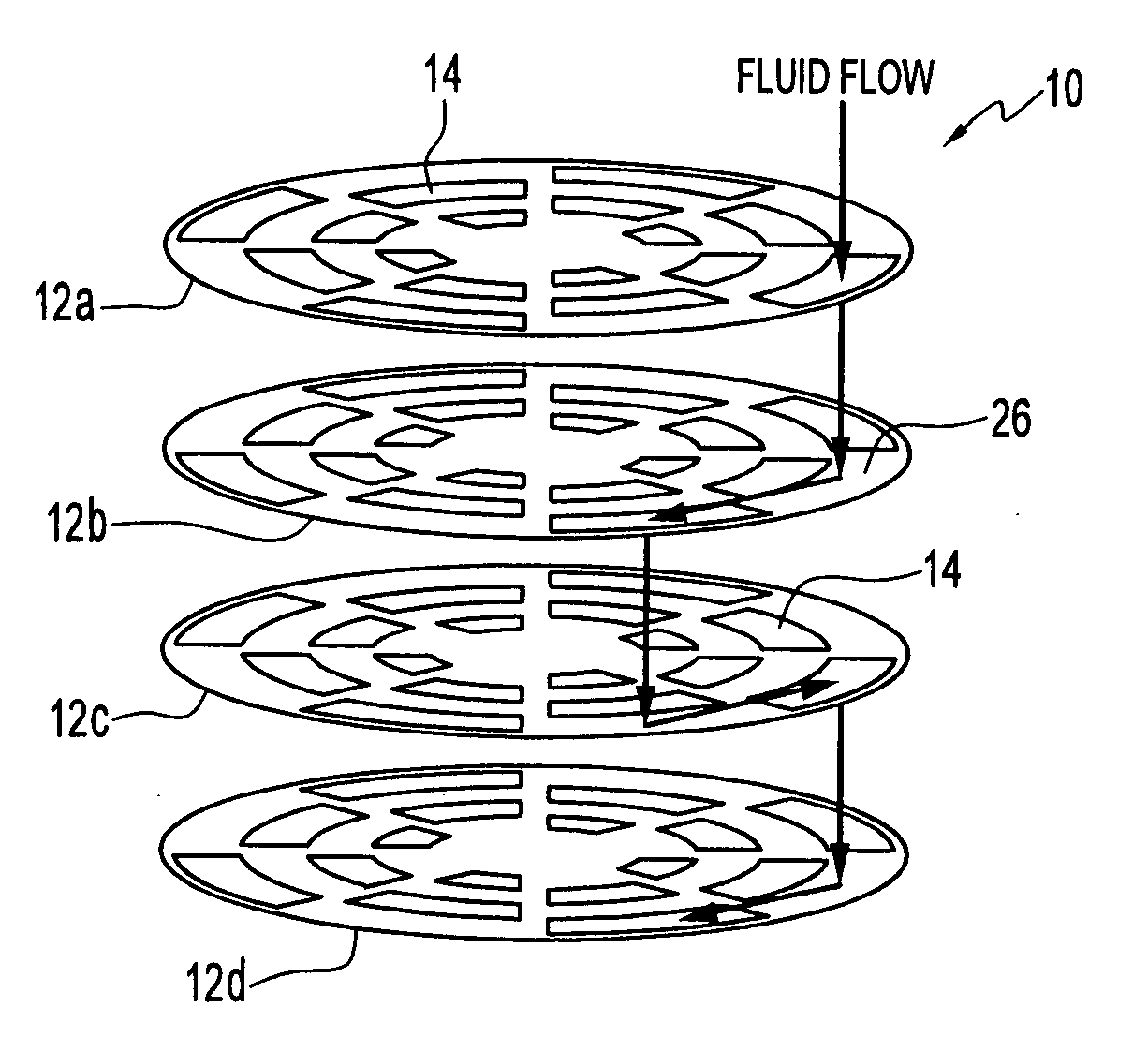

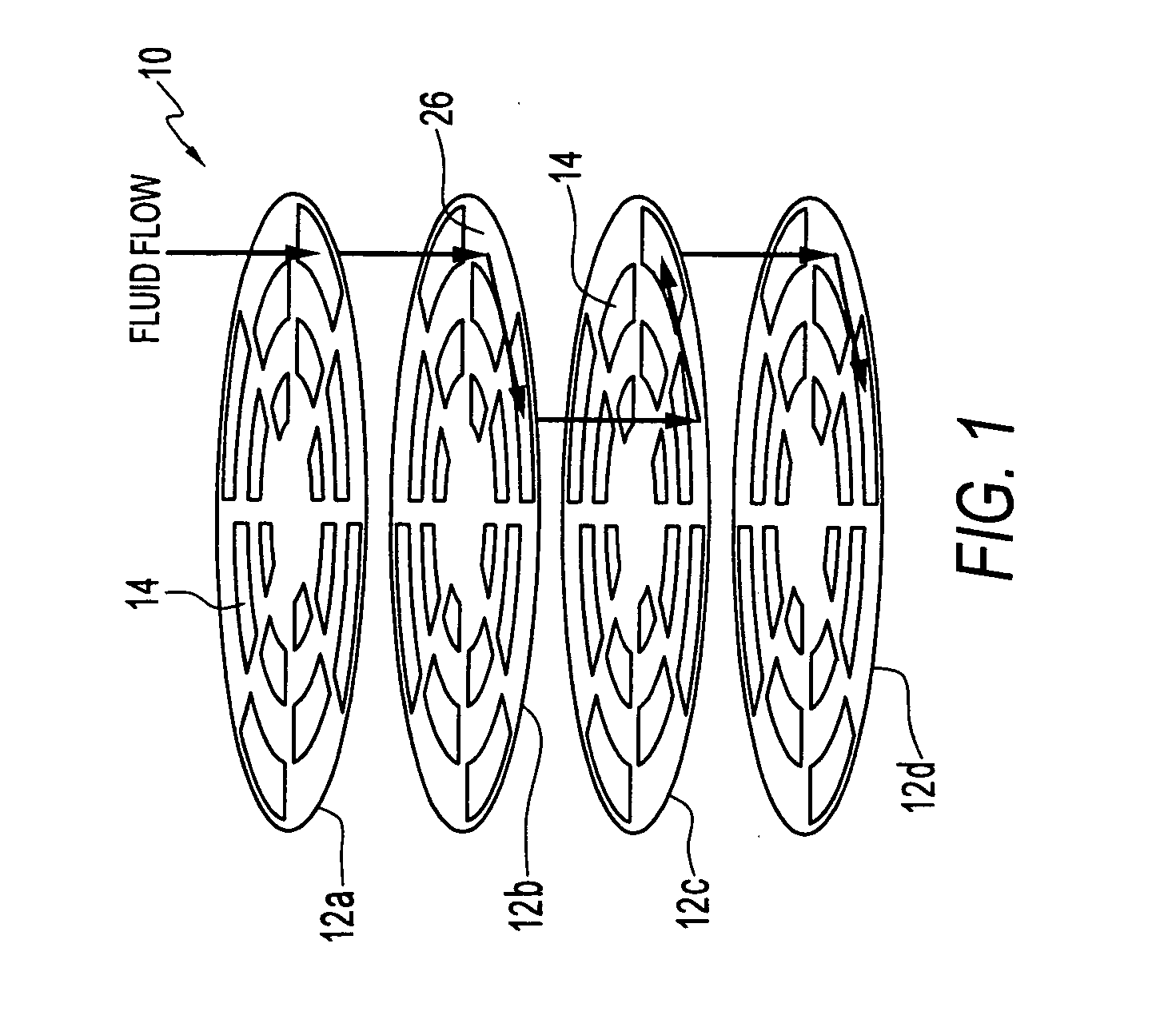

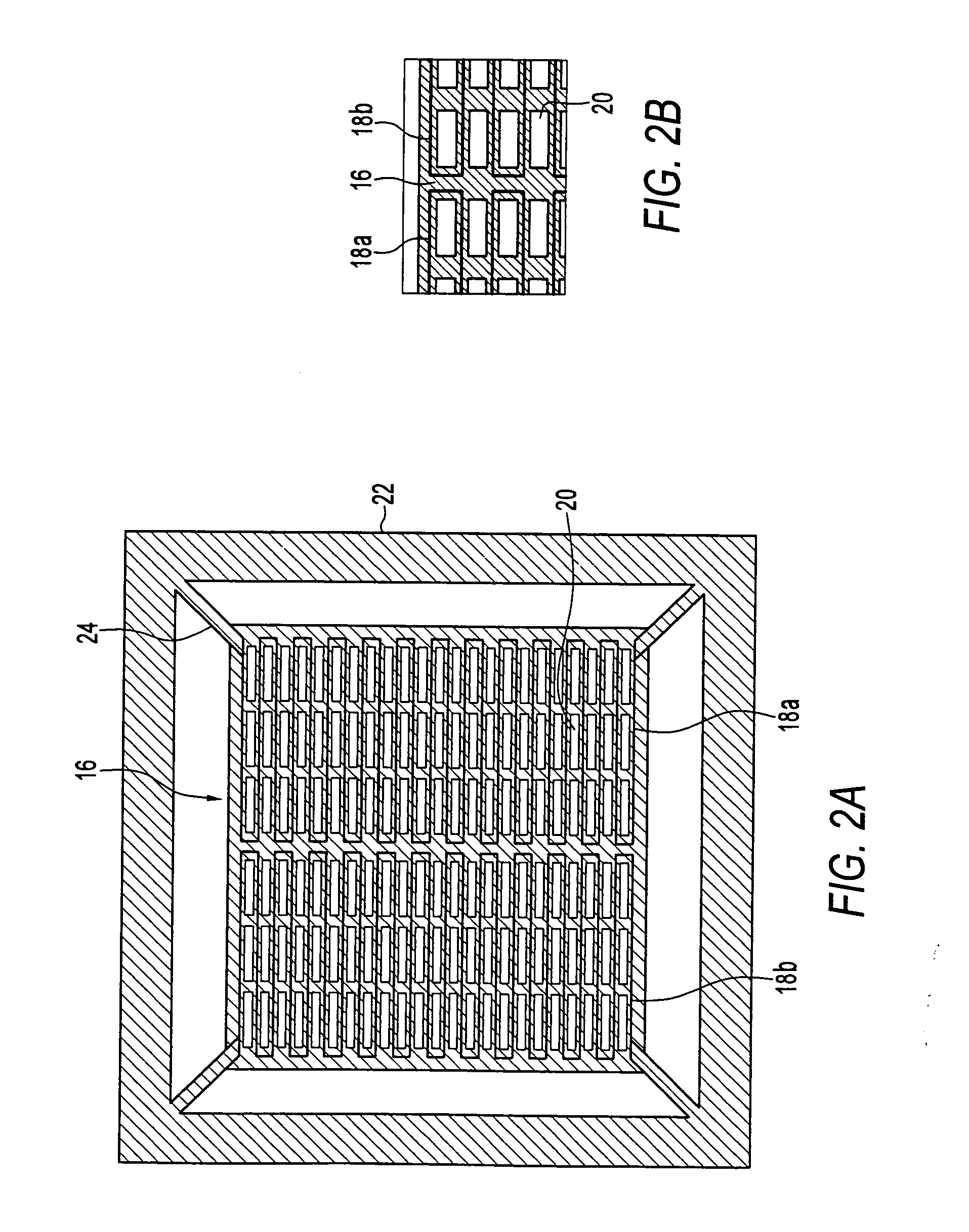

[0031] The invention concerns a collection device having a flow through micro scale plate arranged to collect analyte, and deliver a concentrated pulse of analyte to a detector system upon demand through heating. With the invention, analyte fluid flow is through at least one sorbent plate, which includes holes to pass analyte fluid flow, for example analyte vapor. Fluid flow for collection is generally perpendicular to the sorbent plate. Excellent interaction is achieved between the analyte fluid flow and a sorbent coating on the plate. After a period of collection, analyte may be provided to a detector system from the plate by heating the plate. Preferred embodiment plates include an integrated heater trace.

[0032] Embodiments of the invention use a series of two or more flow through micro scale plates. In preferred embodiments, a series of micro scale plates include a sorbent coating, and holes for analyte fluid flow through the plates. In preferred embodiments, individual plates ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure drop | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com