Valve actuation controlling apparatus and method for engine

a valve actuation and controlling apparatus technology, applied in the direction of electric control, machines/engines, output power, etc., can solve the problems of inability to generate sufficient torque to counteract the increase in friction, and inability to ensure proper engine starting characteristics. , to achieve the effect of improving engine starting characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] An embodiment of the present invention will be described in detail below with reference to the drawings.

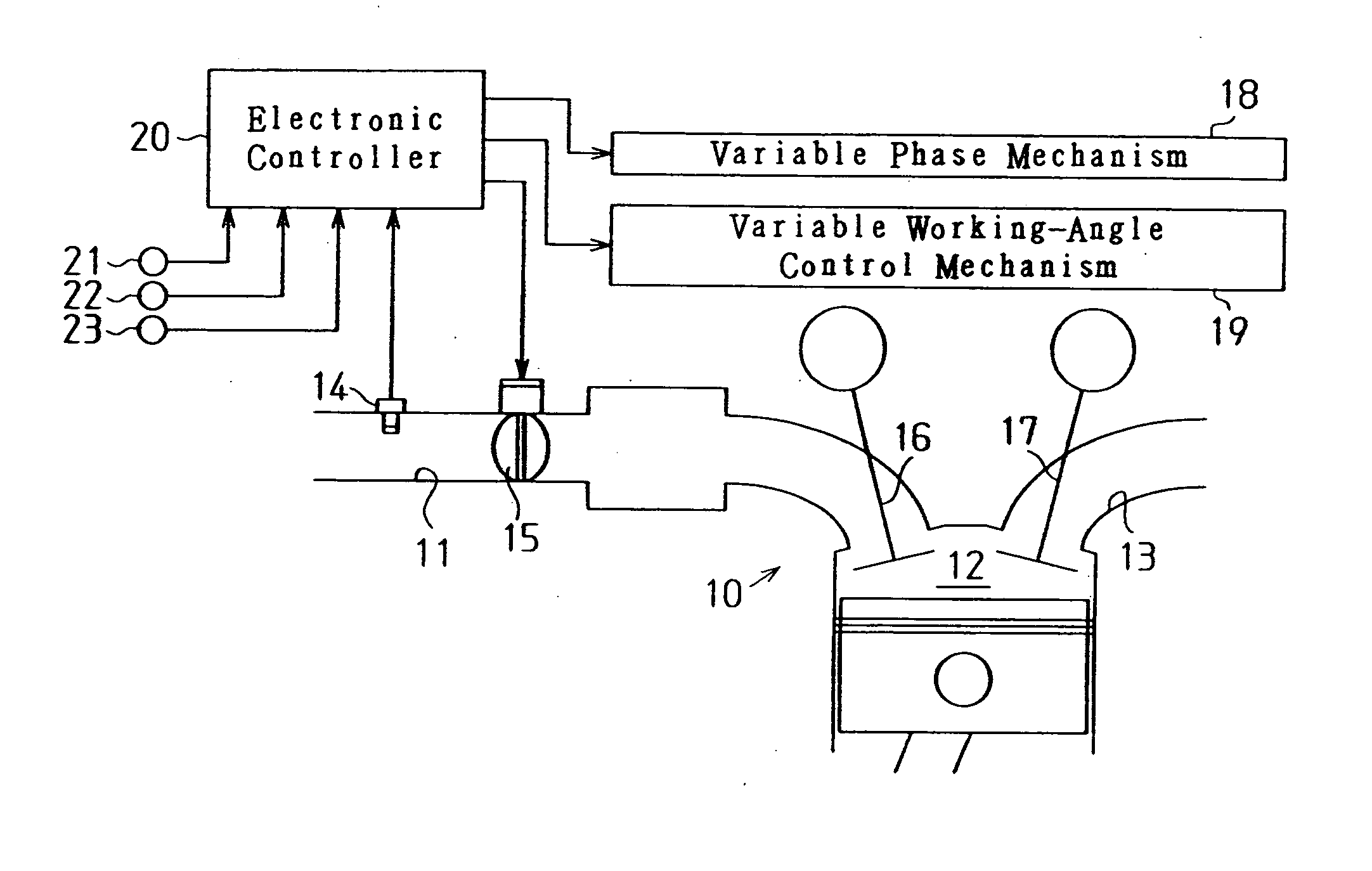

[0026] As shown in FIG. 1, an engine 10 includes an intake passage 11, a combustion chamber 12, and an exhaust passage 13. Installed in the intake passage 11 are an air flowmeter 14 which detects an air flow rate in the intake passage 11 and a throttle valve 15 which changes the air flow rate by changing the flow area of the intake passage 11. The intake passage 11 is connected to the combustion chamber 12 via an intake valve 16. The combustion chamber 12 is connected to the exhaust passage 13 via an exhaust valve 17. The intake valve 16 and exhaust valve 17 are driven according to rotation of the engine 10. The intake valve 16 opens and closes the intake passage 11 to the combustion chamber 12, and the exhaust valve 17 opens and closes the exhaust passage 13 to the combustion chamber 12.

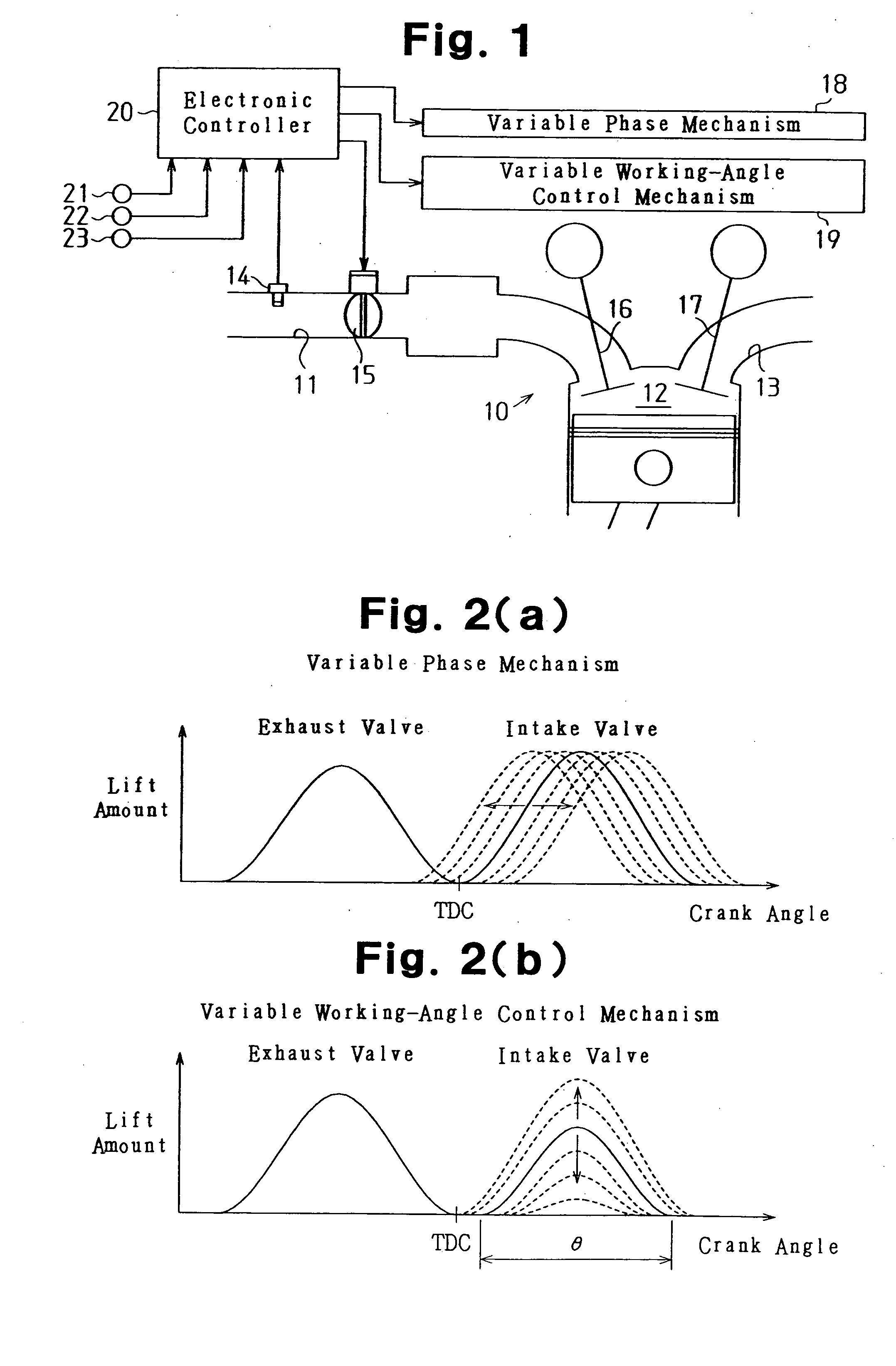

[0027] A valve operating system of the intake valve 16 has a variable phase mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com