Windshield liquid wash heater

a liquid wash heater and windshield technology, applied in the direction of vehicle cleaning, domestic stoves or ranges, ways, etc., can solve the problems of affecting vision, affecting the cleaning effect, and accumulating ap-like deposits, and achieve the effect of rapid heating of liquid and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

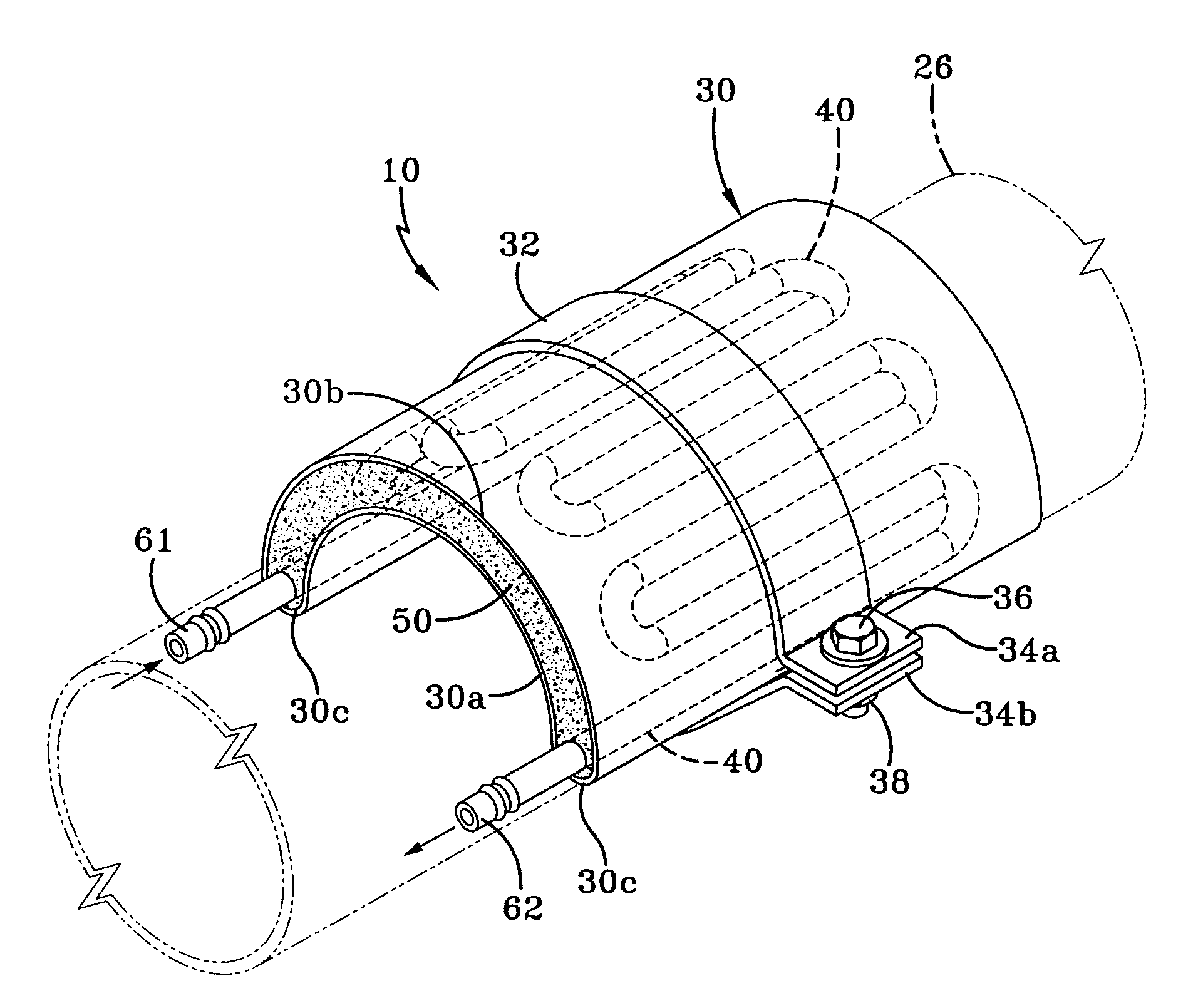

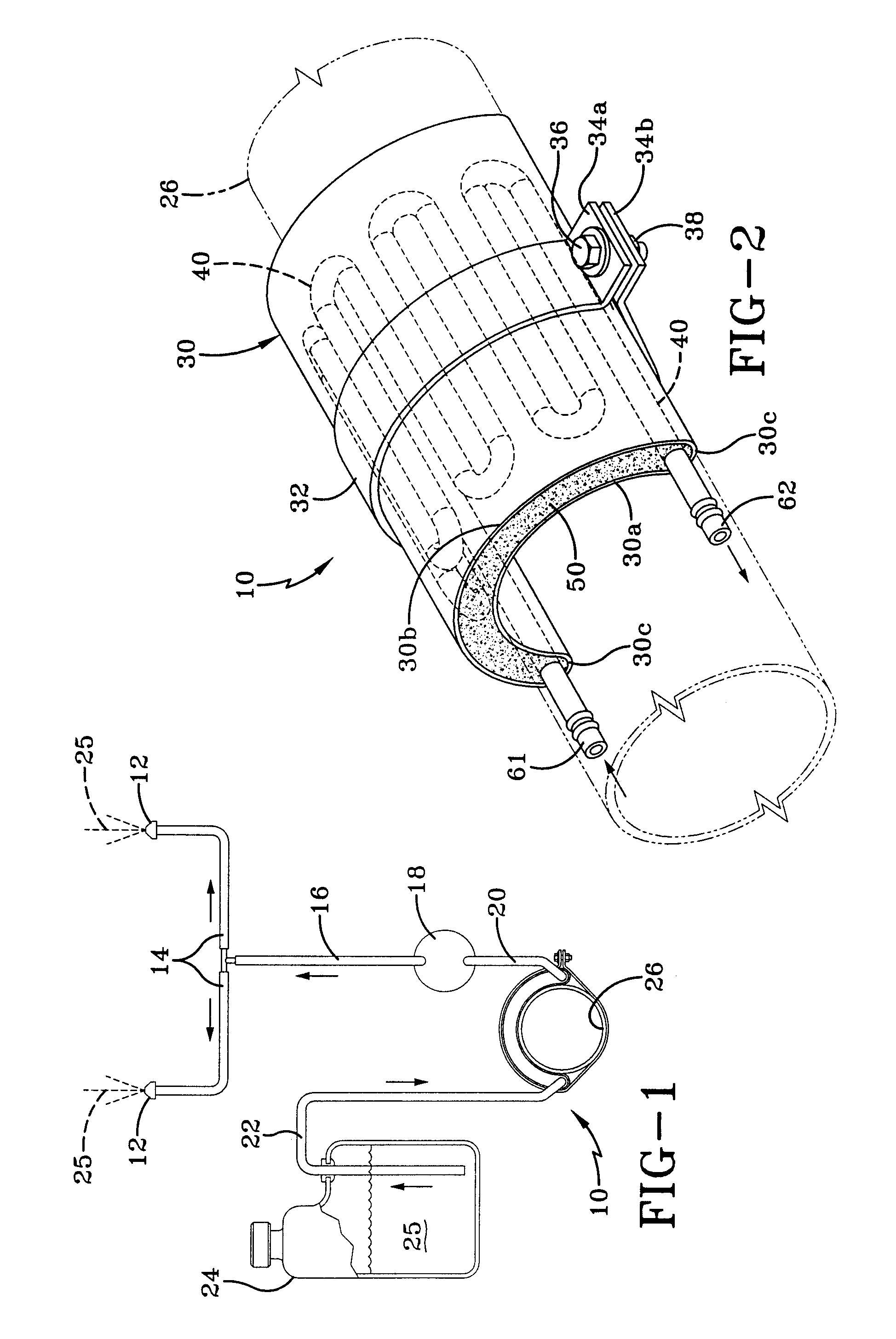

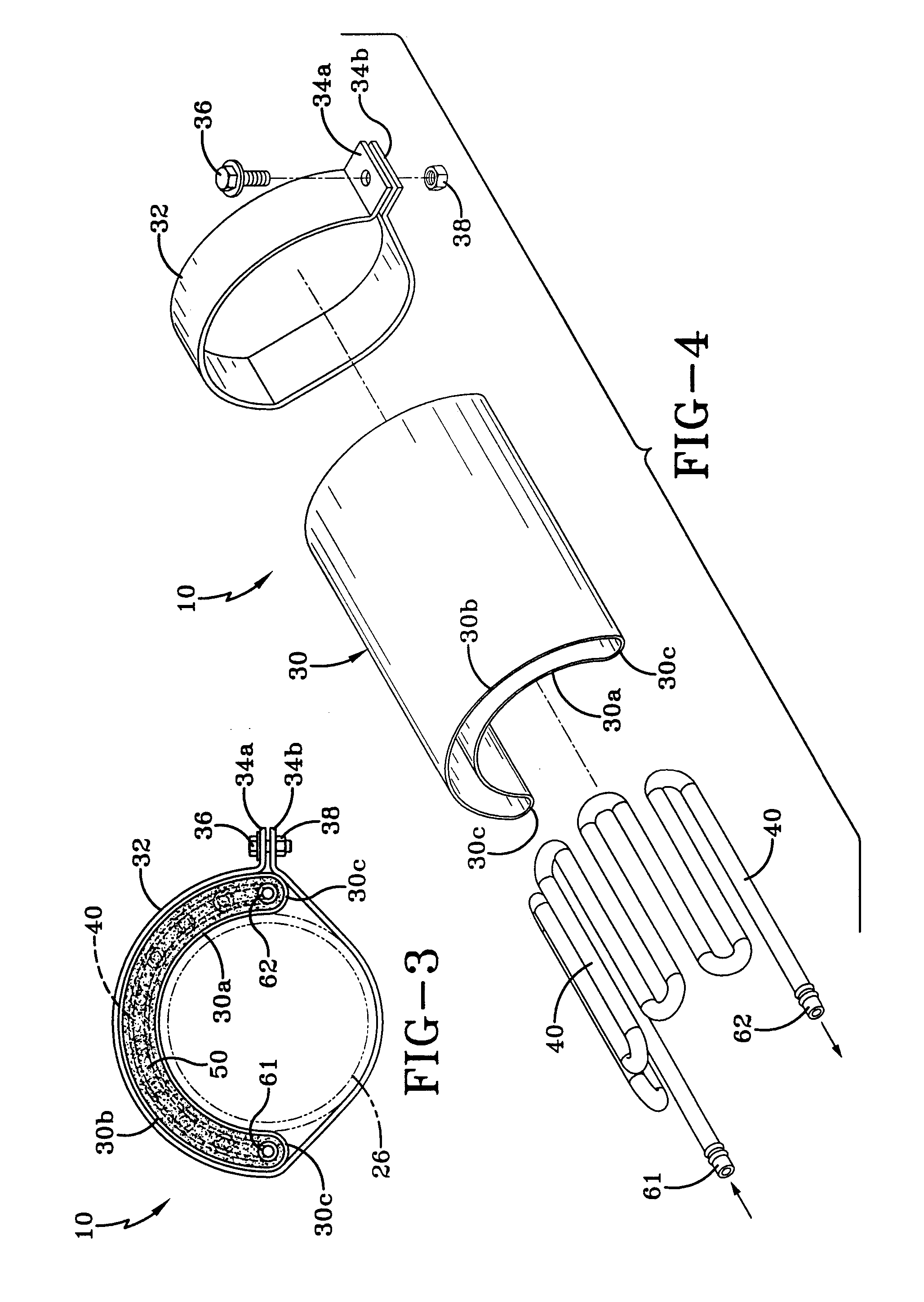

[0021] In the drawings, FIG. 1 schematically represents use of heater unit 10 of the present invention as hereinafter described in an automotive vehicle environment, namely in a windshield washer system, wherein the washer jets 12 are supplied with heated liquid wash, such as water in combination with other freezing point depressants or any other commercially available windshield wash fluid, through pump output lines 14 and 16 by pump 18 with intake connected by pump intake line 20, the heater 10 and heater inlet line 22 to the liquid wash supply vessel 24 and liquid wash 25. Heater 10 is held in thermally conductive contact and heat transferring proximity with the engine exhaust manifold or the exhaust pipe 26 to warm the liquid wash passing there through.

[0022] Heater 10, in general form, is symmetrical about a longitudinal center plane having a longitudinally straight transversely concave bottom recess 30a and a hemispherical top 30b connected by sides 30c; providing top and sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com