Deep hole drill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

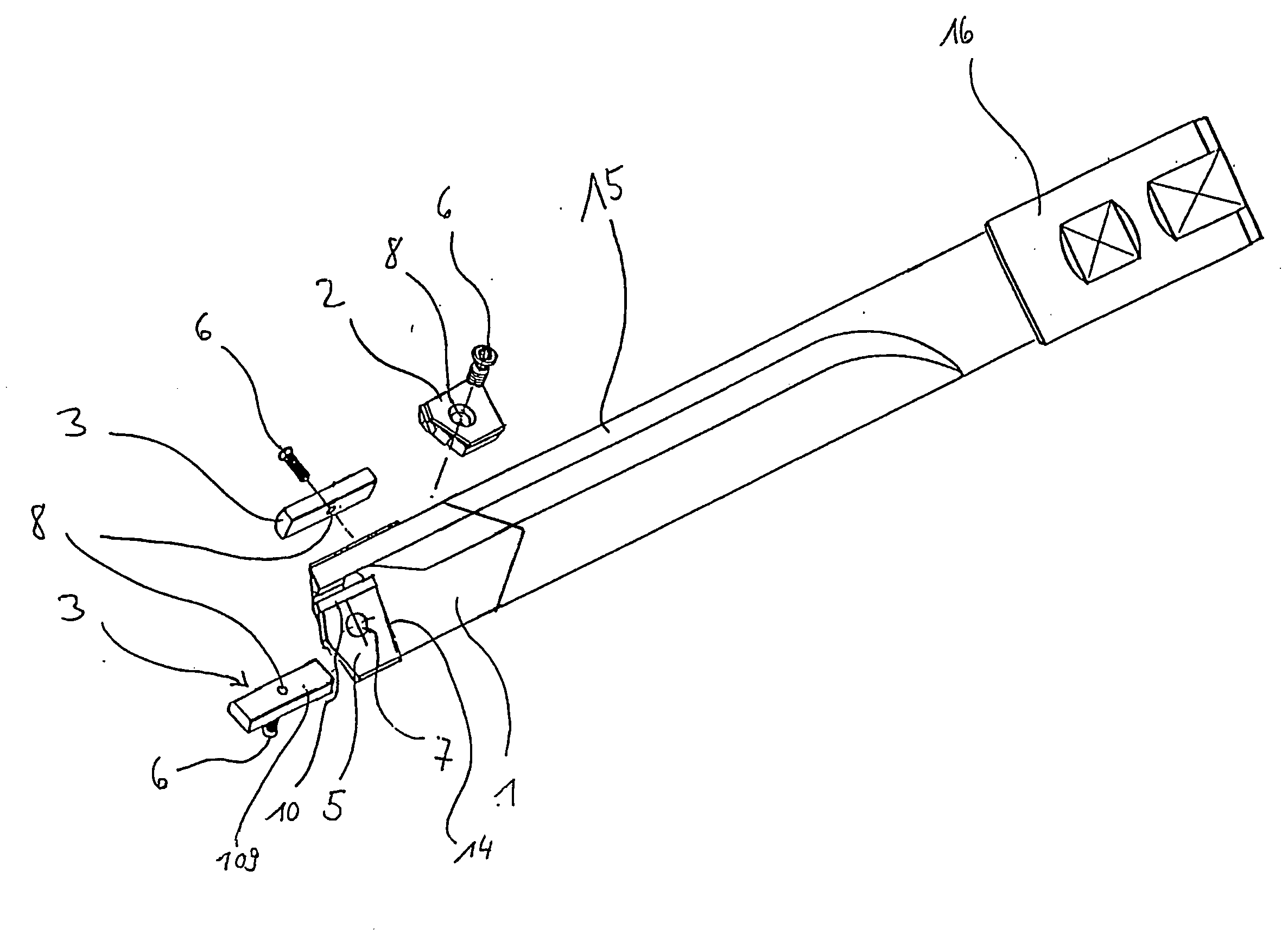

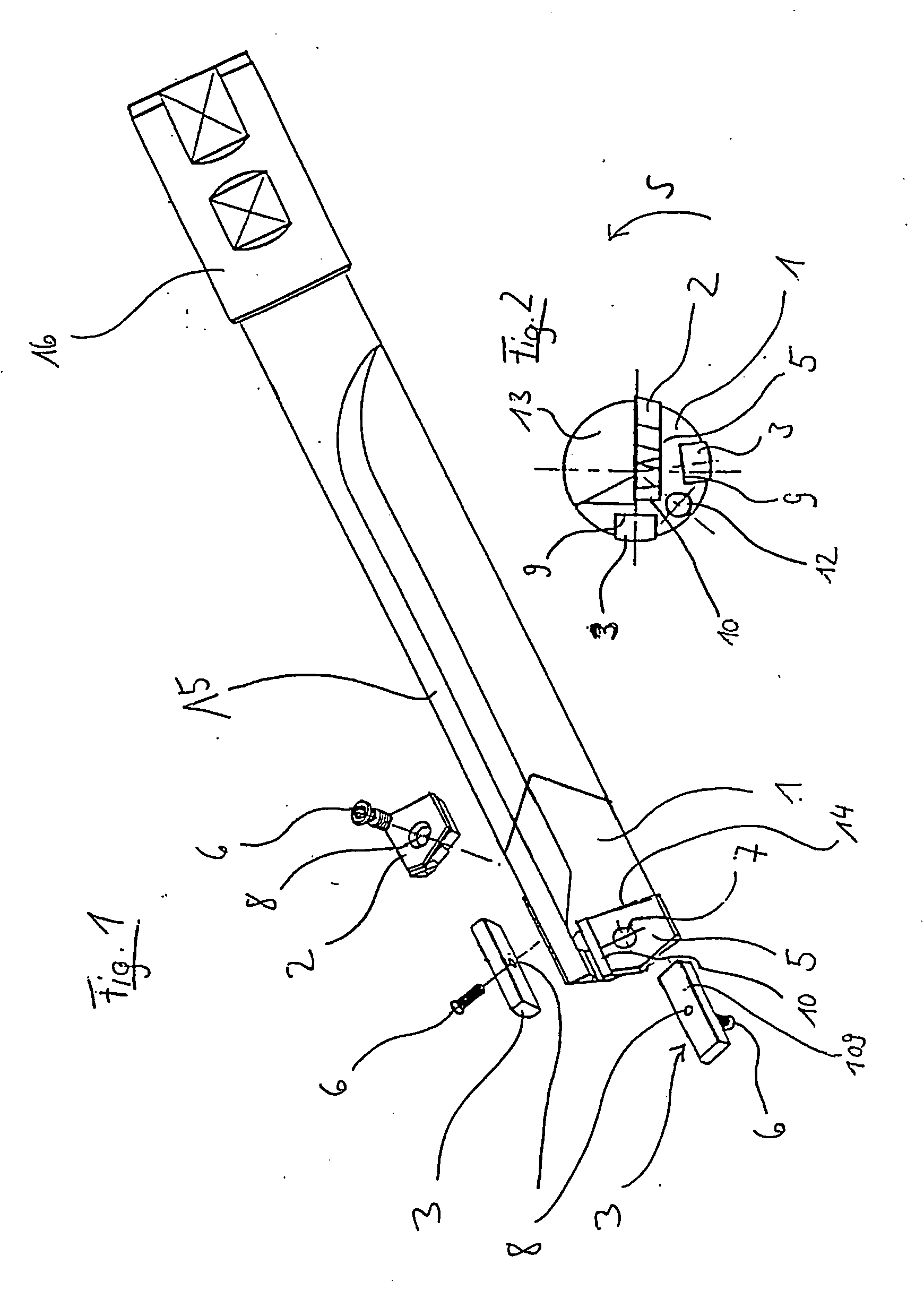

[0041] Reference is first made to FIGS. 1 and 2 which show a single-lipped embodiment of the deep hole drill according to the invention. The reference number 1 designates a drill head which is soldered onto a drill shank 15 which in turn is soldered into a clamping sleeve 16. The machined groove is substantially v-shaped where the angle spanned by the machined and unmachined surface is approximately 90°.

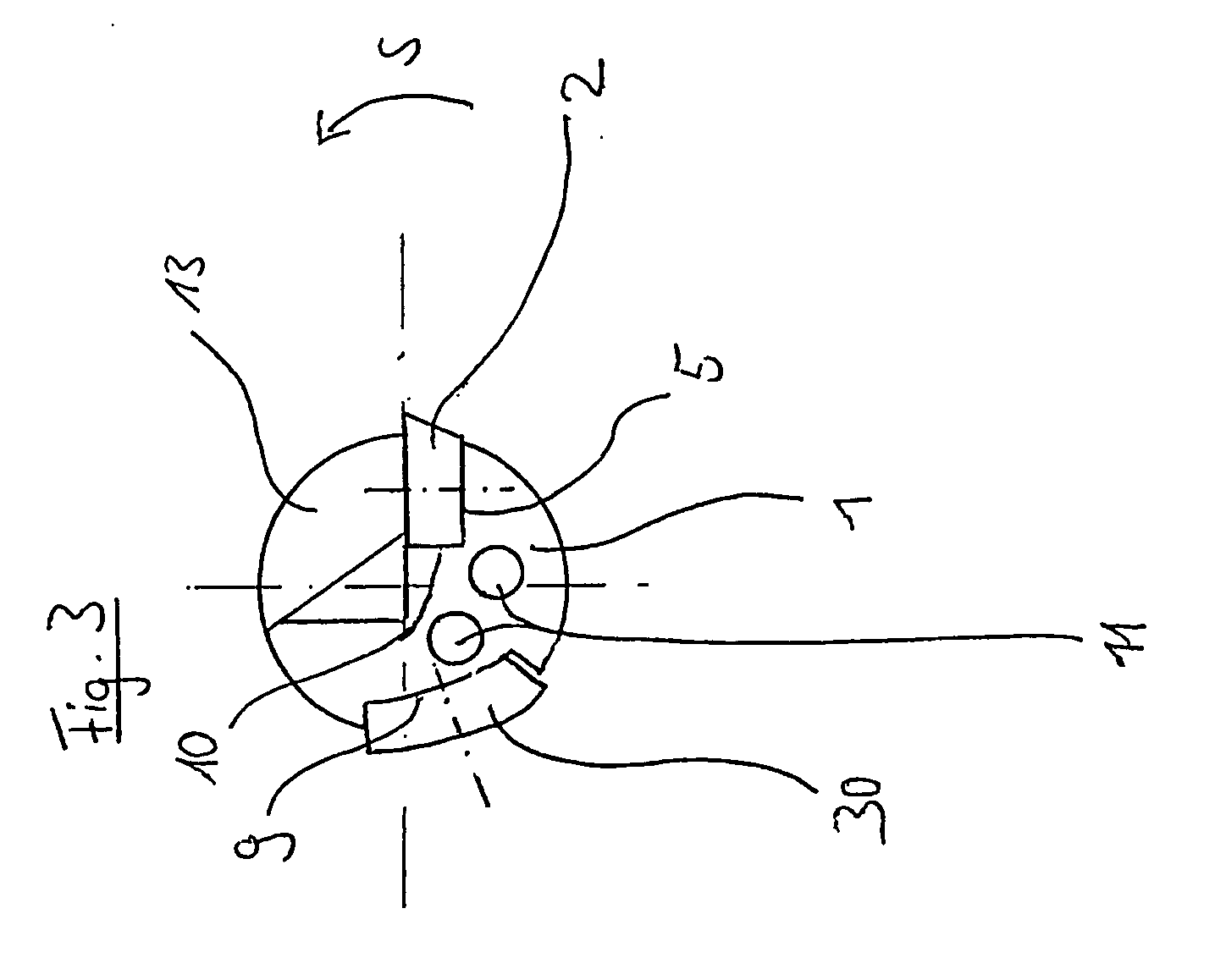

[0042] At its tip, on the machined surface of the machined groove 13 the drill head has a recess which with its rear surface 5 and the two side surfaces 10, 14 forms a seat for a replaceable cutting plate 2. A central threaded hole 7 is drilled into the rear surface 5 which receives a screw 6 guided through a through hole in the replaceable cutting plate 2.

[0043] Furthermore, at the axial height of the replaceable cutting plate seat two recesses for guide strips 3 are provided over the circumference of the drill, which abut against a stop surface 9 with their radially-pointing plan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com