Sputtering device

a technology of sputtering device and substrate, which is applied in the direction of electrolysis components, vacuum evaporation coatings, coatings, etc., can solve the problems of increasing the cost of enlarge the target, and limiting the activity ratio, so as to reduce the cost and increase the yield rate of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

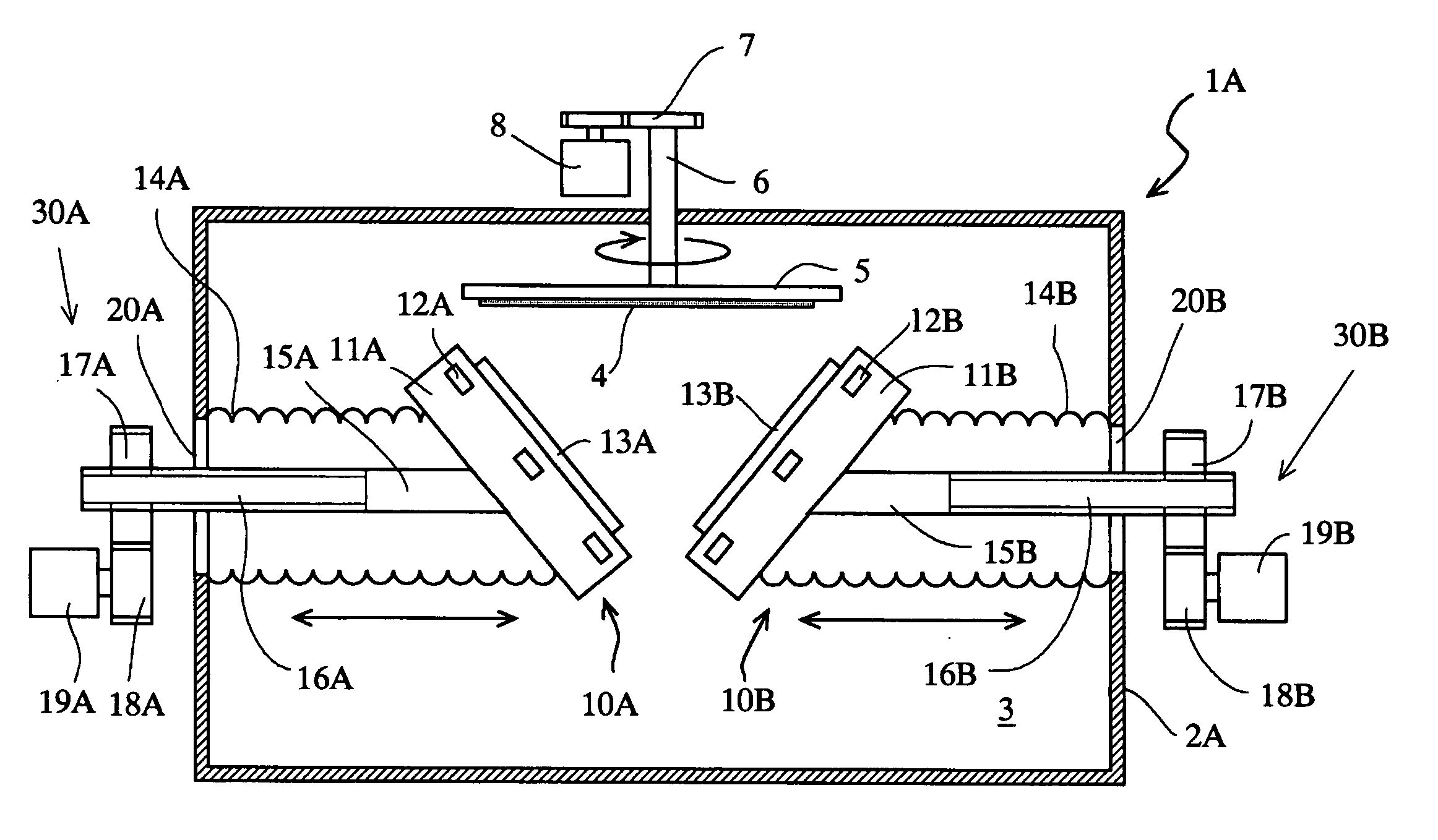

[0017] As shown in FIG. 1, a sputtering device 1 according to this invention comprises at least a vacuum container 2 defining a vacuum space 3, a substrate holder 5 holding a substrate 4 as a work in the vacuum container 2, and a sputtering cathode device 10 for sputtering to the substrate 4 held on the substrate holder 5. According to thus constitution, basically, gas for sputtering is introduced into the vacuum container 3 and a minus voltage is applied to a target 13 provided in the sputtering cathode device 10, so that sputter particles are radiated from the target 13 to the substrate 4 installed in the vacuum container 3 to form a thin film on the substrate 4.

[0018] Besides, the substrate holder 5 is rotated at a specific speed via a rotation shaft 6 and gears 7 by a electric motor 8 as a drive means. The rotational speed is variable by an outer control device not shown in figures and is set at a specific rate according to materials or thickness of the thin film formed on the s...

second embodiment

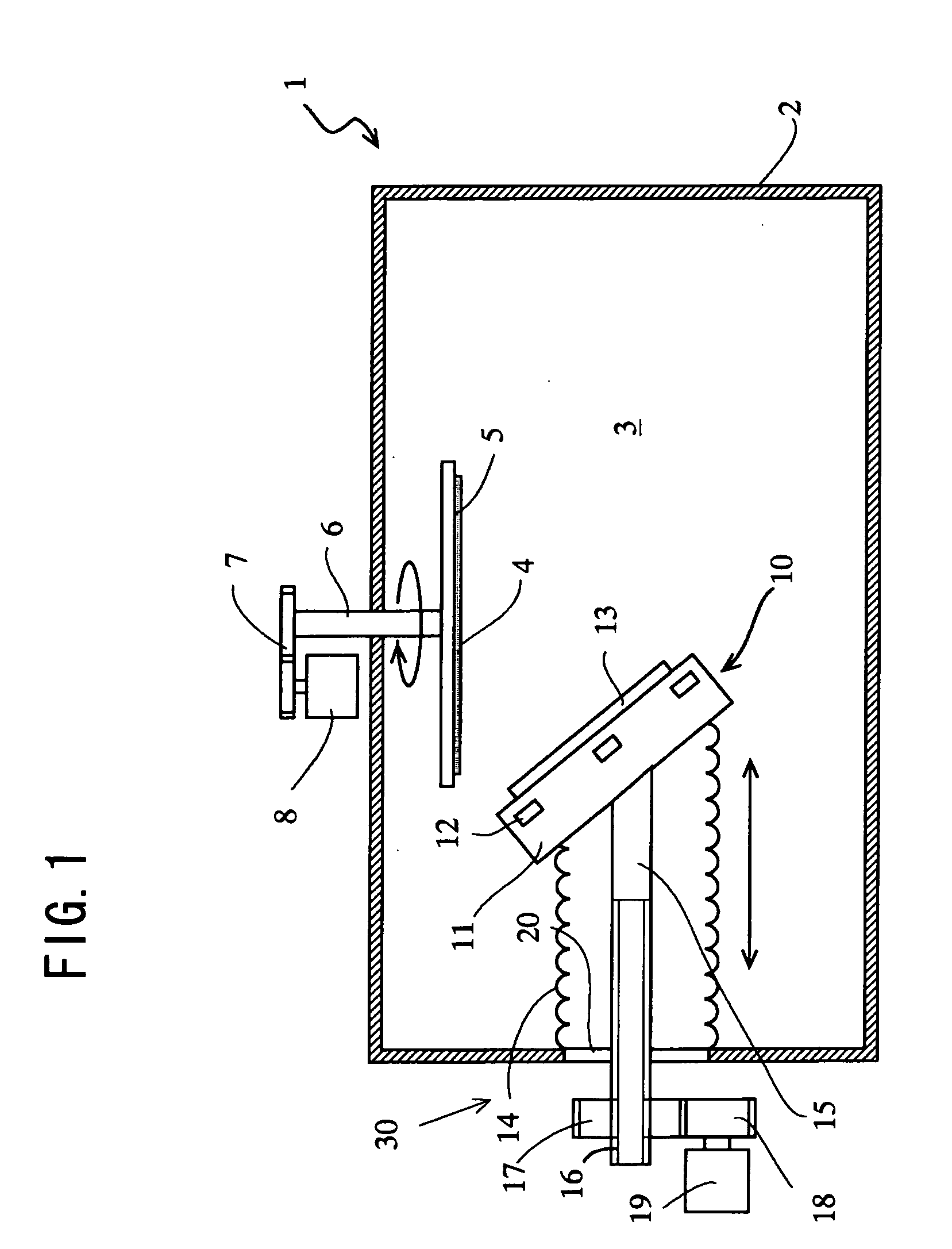

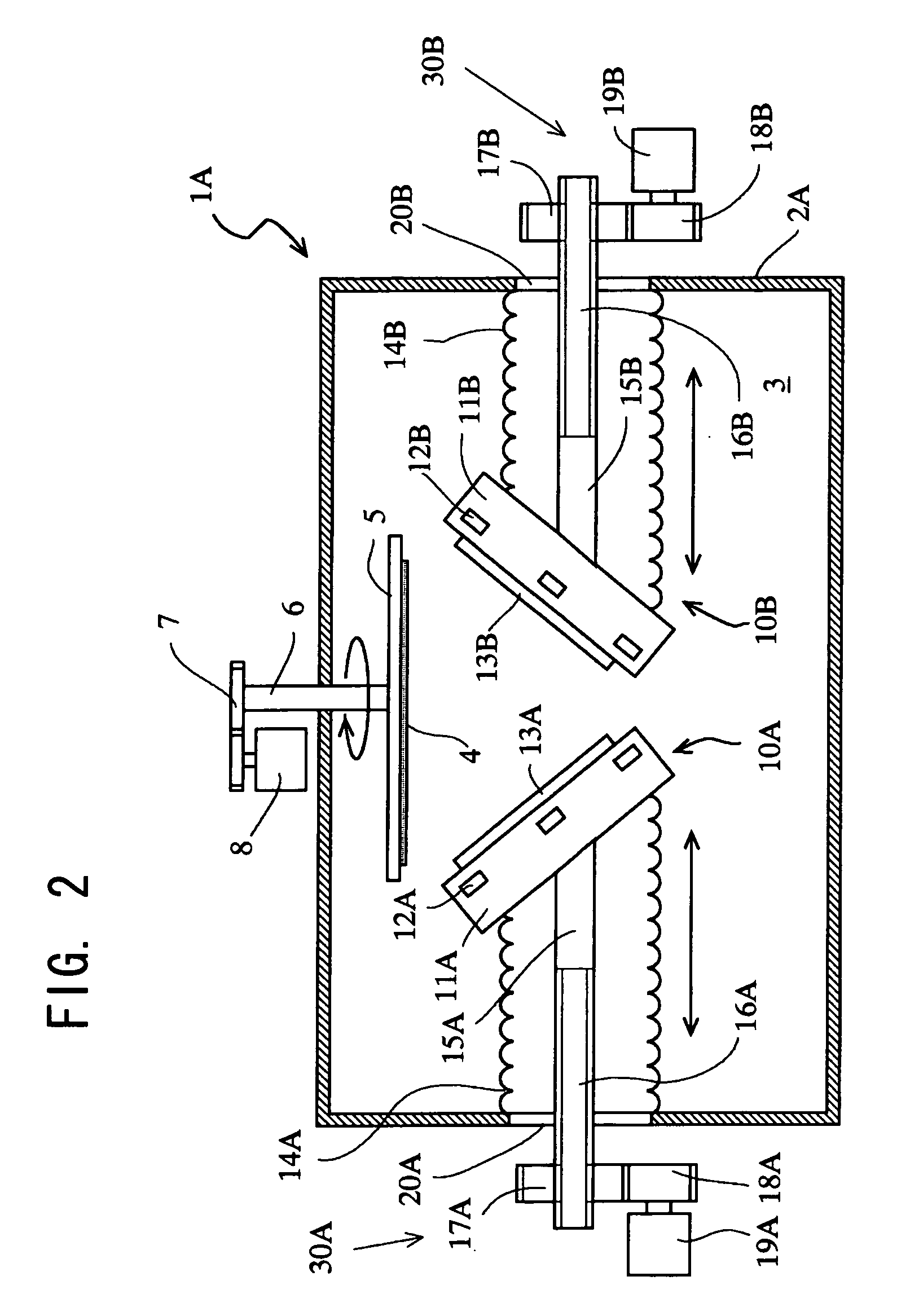

[0024] A sputtering device 1A according to the invention as shown in FIG. 2 is characterized in that plural sputtering cathodes 10A, 10B which are similar to or the same as the sputtering cathode device 10 are provided at specific intervals in a circumferential direction of the substrate 4.

[0025] The sputtering cathode device 10A, 10B are constituted of cathode unit 11A, 11B which are arranged slantly at a specific angle to the substrate 4, and movement unit 30A, 30B which make the cathode units 11A, 11B in parallel along the radial direction of the substrate 4, respectively.

[0026] The movement units 30A, 30B are, in the second embodiment, constituted of moving rods 15A, 15B which pass through openings 20A, 20B formed in the vacuum container 2, whose one ends are secured on the cathode units 11A, 11B and which have screw portions 16A, 16B formed spirally within specific areas at the other ends thereof, and driving gear 17A, 17B including inner teeth screwed on the screw portions 16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific angle | aaaaa | aaaaa |

| specific speed | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com