Sheet feeding apparatus and method of detecting double feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereunder, preferred embodiments of the present invention will be explained with reference to the accompanied drawings. The invention applies to an apparatus and a method for detecting a double feed of two or more overlapped sheets before reaching a processing position when the sheets stacked on a stacker in a sheet feeding unit of an image reading apparatus such as a copier, or printer are separated and transported one by one to the processing position such as an image reading platen, or printing platen.

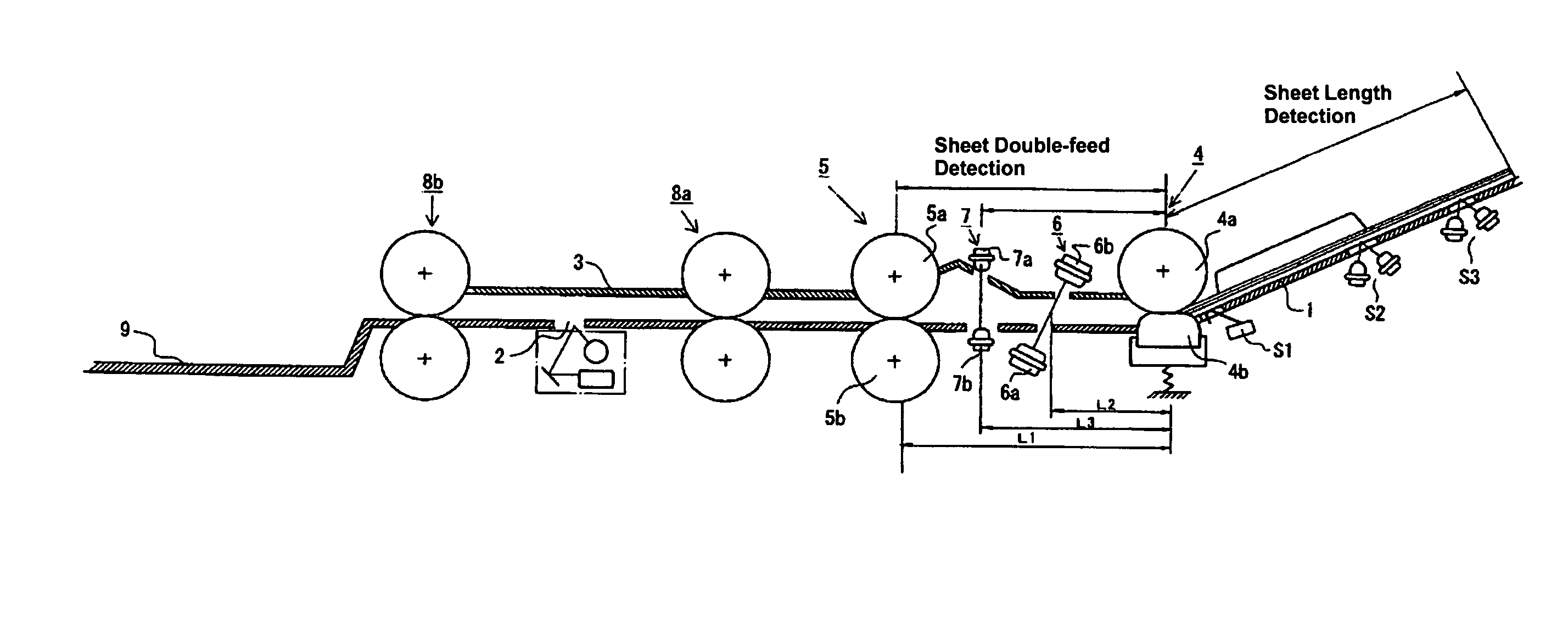

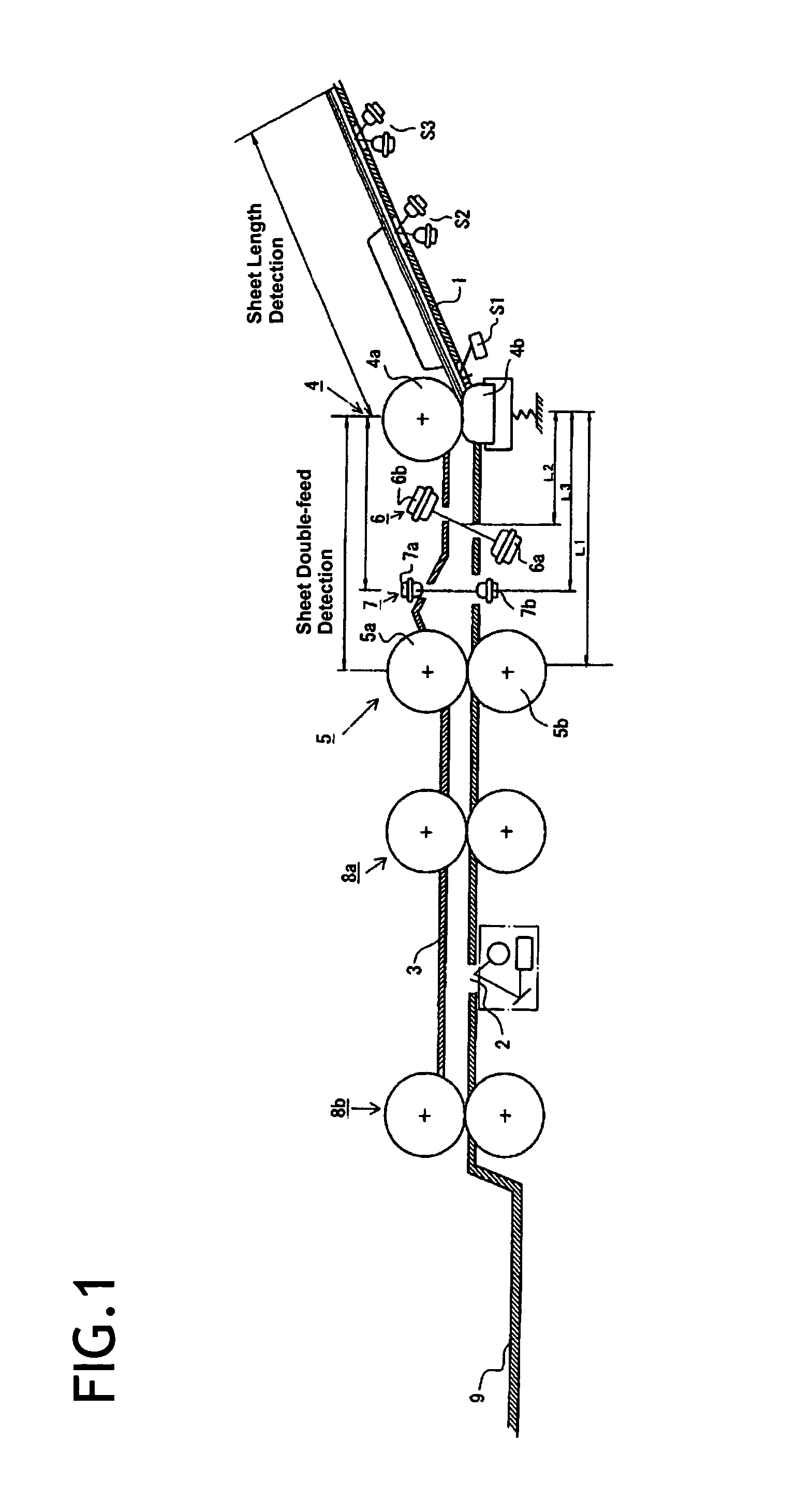

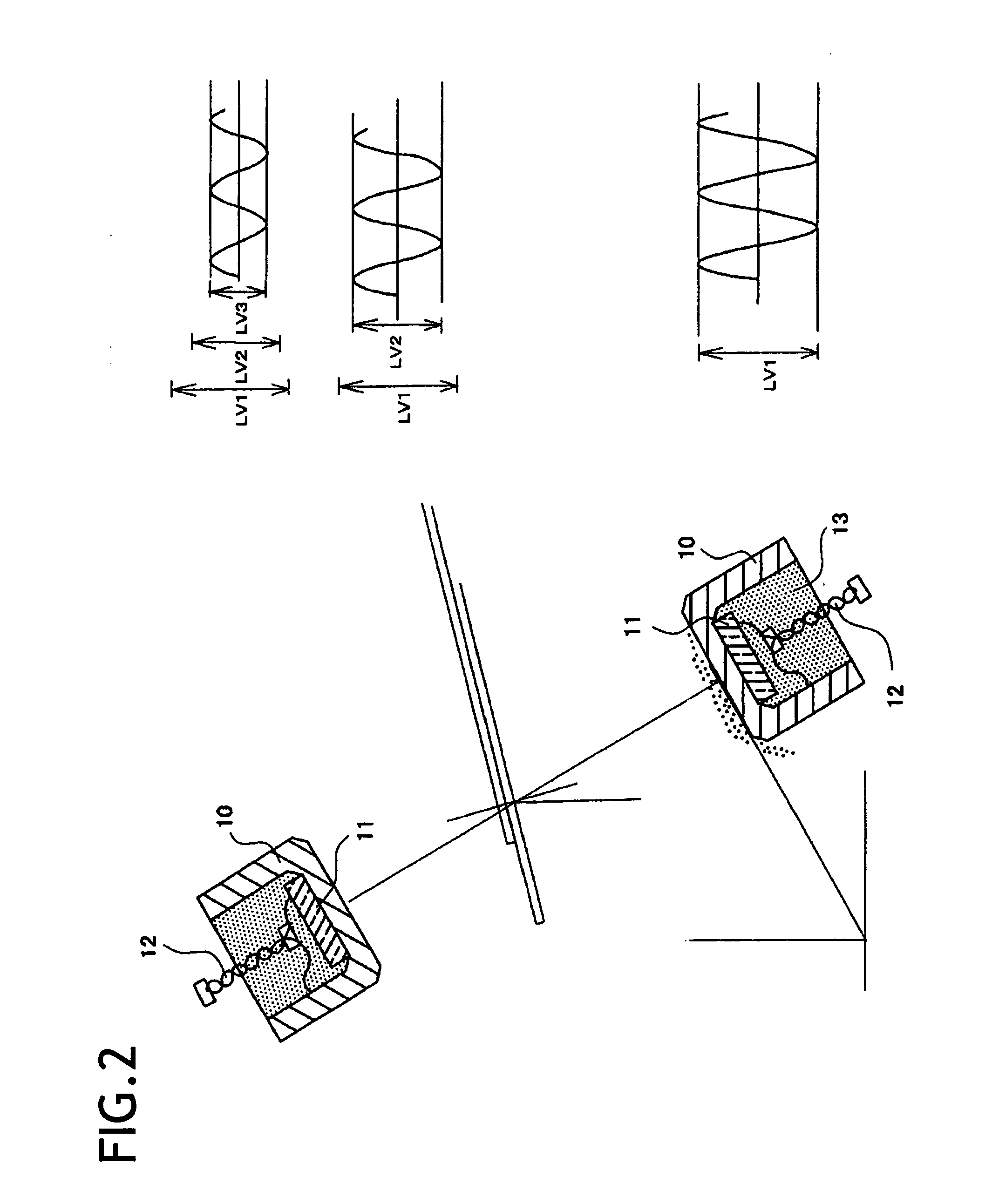

[0031]FIG. 1 is a schematic view of a sheet feeding mechanism according to an embodiment of the present invention. FIG. 2 is a schematic view of a double feed detection device composed of an ultrasonic wave sensor. FIGS. 3(a) and 3(b) are circuit diagrams of a control circuit.

[0032] As shown in FIG. 1, the sheet feeding apparatus is equipped with a stacker 1 for storing sheets; a sheet guide 3 for guiding the sheets from the stacker 1 to the processing platen 2; at least tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com