Flat wide-angle objective

a wide-angle objective and flat technology, applied in the field of flat wide-angle objectives, can solve the problems of inconvenient use and storage, increased overall radius and hence the dimension of the lens system, and achieve the effect of reducing the overall dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

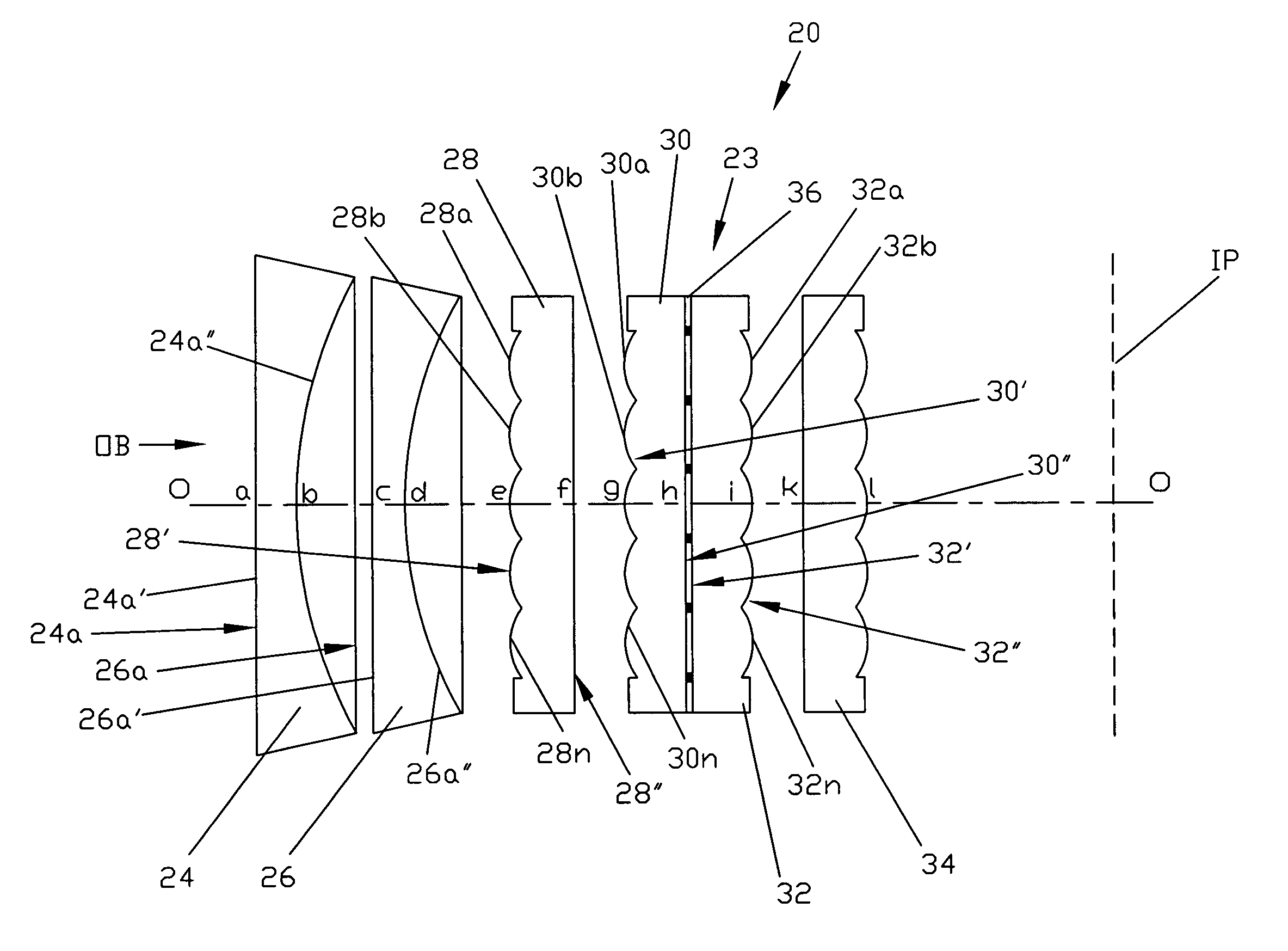

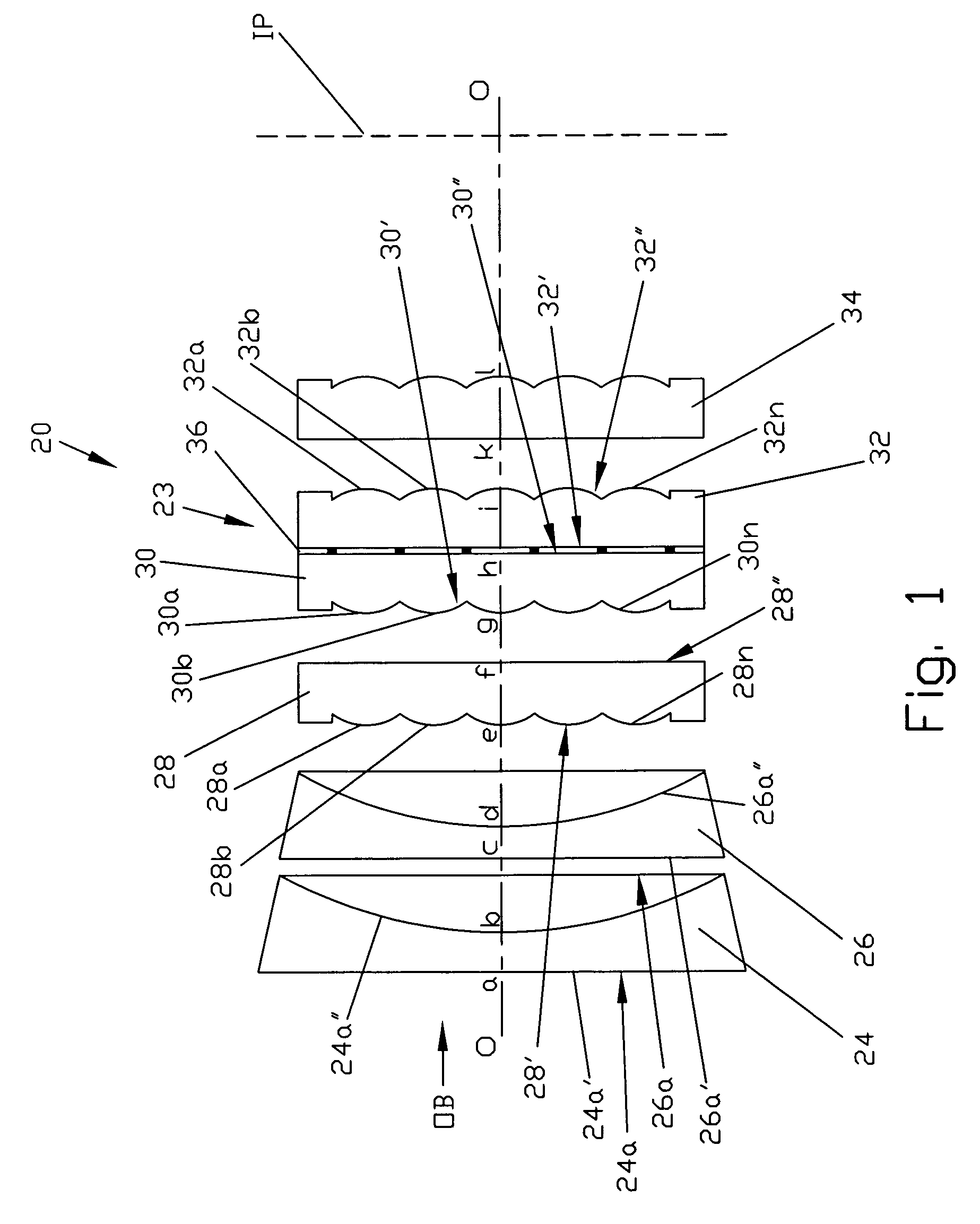

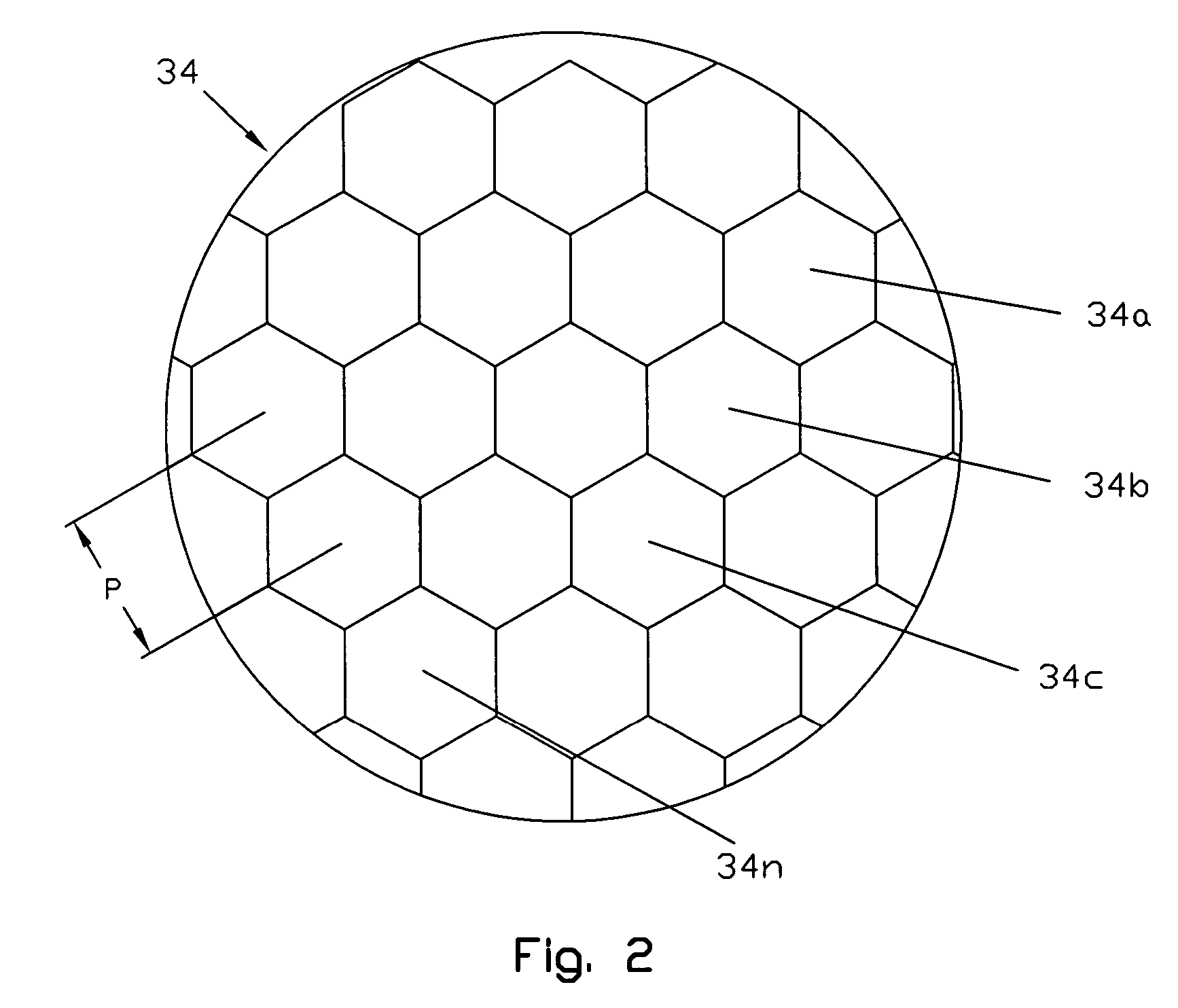

[0037] A flat wide-angle lens system of the invention, which herein after will be referred to as an objective of the present invention, is shown in FIG. 1 which is a general longitudinal sectional view of the aforementioned objective. The objective of the invention as a whole is designated by reference numeral 20. The objective 20 consists of two sub-assemblies. The first sub-assembly 22 that is located on the object side OB, which is on the left side in the view of FIG. 1, comprises an assembly of two conventional negative aspheric lenses 24 and 26, having their flat sides 24a and 26a, respectively, facing the object side OB. The second sub-assembly 23 is a set of four microlens arrays 28, 30, 32, and 34 arranged on the image-receiving side IP, which is on the right side of the view of FIG. 1. Reference numeral 36 designates a diaphragm array, which will be described later in consideration of the second sub-assembly 23.

[0038] Now the aforementioned sub-assemblies 22 and 23 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com