End effector with force controlling mechanism

a technology of force control mechanism and end effector, which is applied in the direction of programme control, thin material processing, programme control, etc., can solve the problems of unresolved contamination problems, confusion involved, and add unnecessary complexity to equipment design, etc., and achieve high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

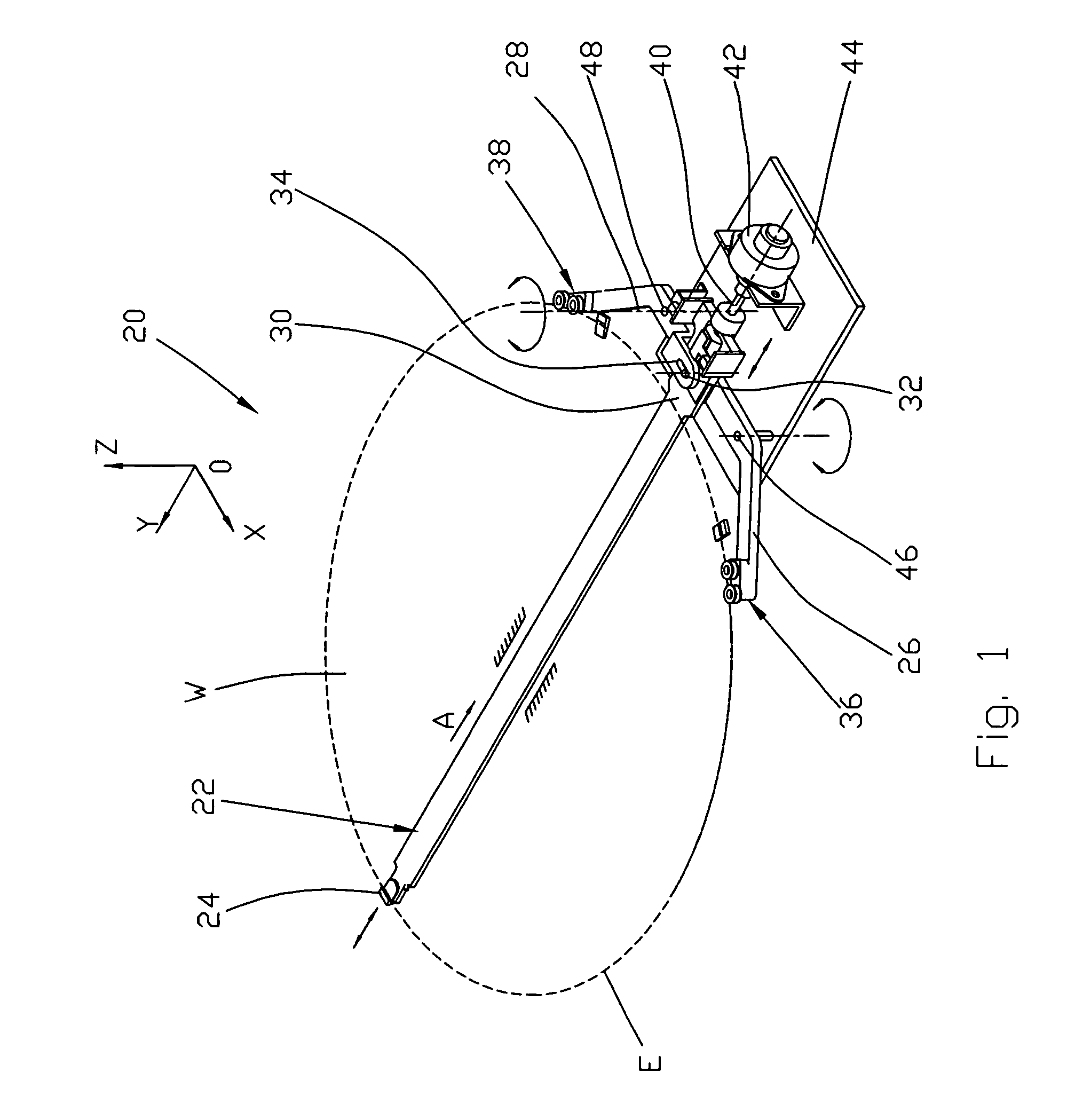

embodiment

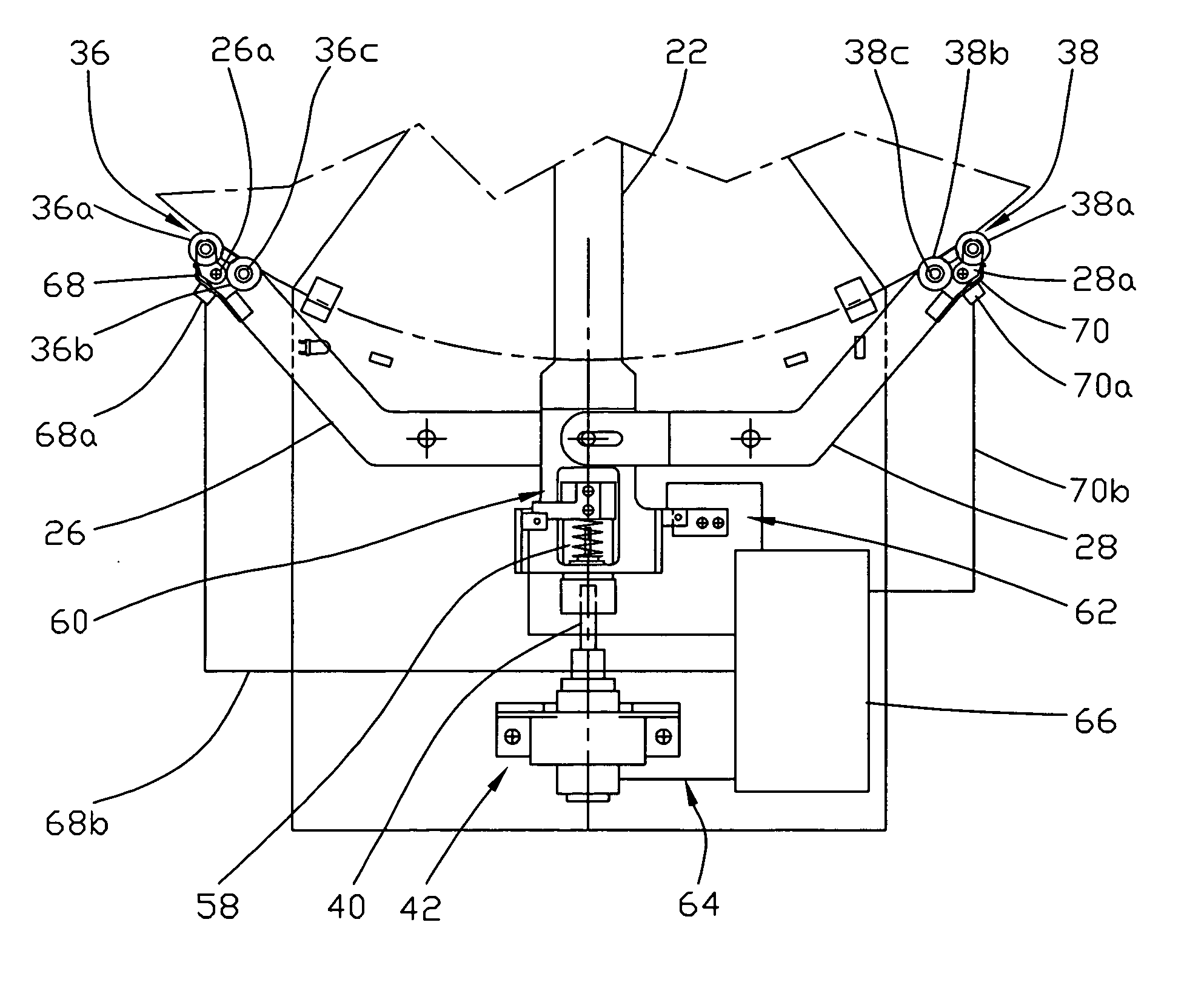

of FIG. 11

[0072] Since the end effector 20A of this embodiment is similar to the end effector 20 of the previous embodiment, a detailed description of its operation is omitted. It should only be noted that during the gripping cycle the actuator 40A of the stepper motor 42A (FIG. 11) moves the slide 33A in the direction opposite to arrow B, whereby the arms 26A and 28A turn around the pins 46A and 48A and move toward each other and hence move the posts 36A and 38A toward the edges E of the wafer W shown in FIG. 11 by a broken line. As the distal post 24A is rigidly connected to the base plate 44A, it remains stationary during the gripping cycle. In this case, unloading of the wafer is carried out by moving the robot arm (not shown) in the direction of arrow B. In this case, for unloading of the wafer the arms 26A and 28A should be spread apart to a sufficient distance, and the wafer will slip down to the resting position.

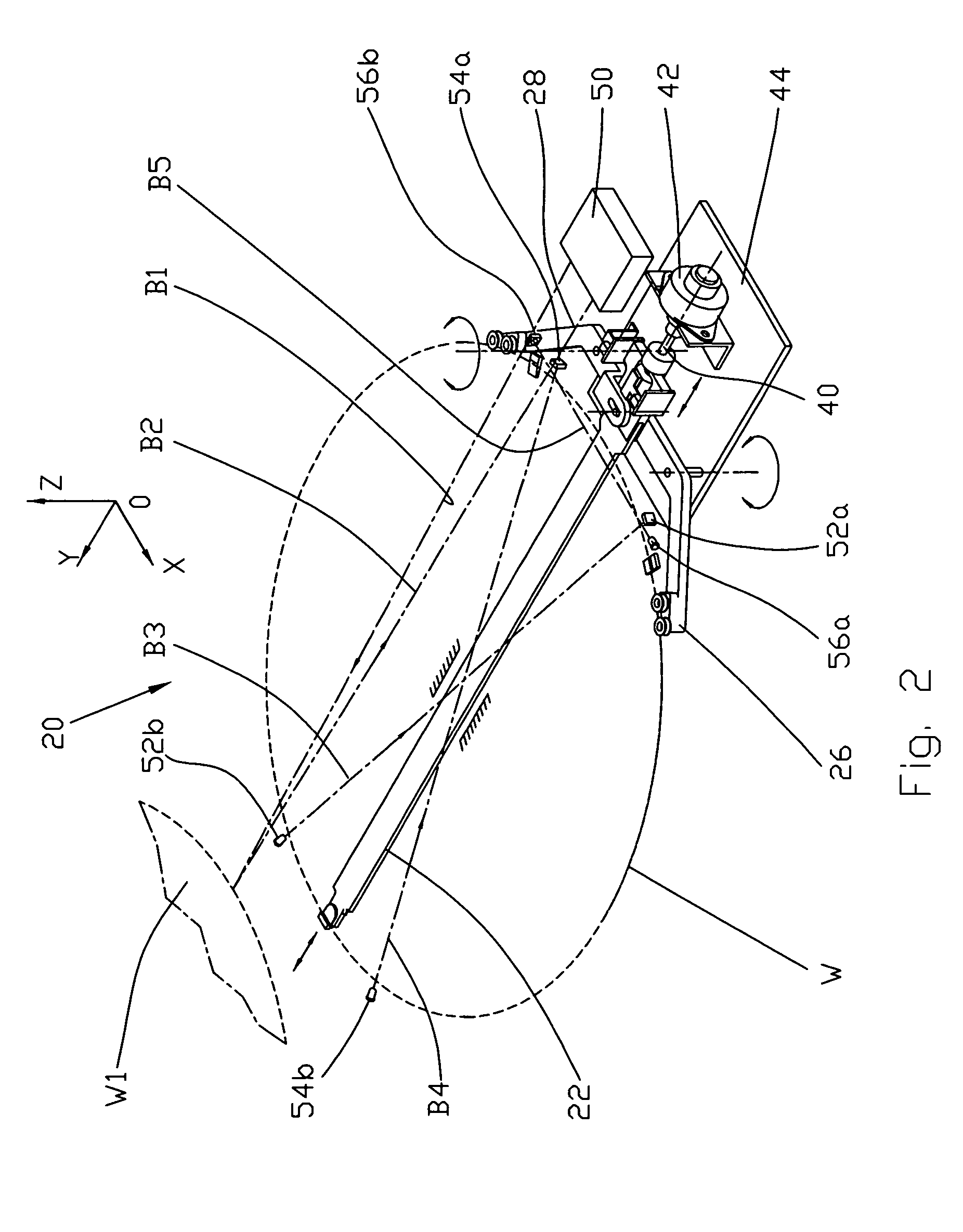

Embodiment of FIG. 12

[0073] Since the end effector 20B of this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com