Cast flapper with hot isostatic pressing treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

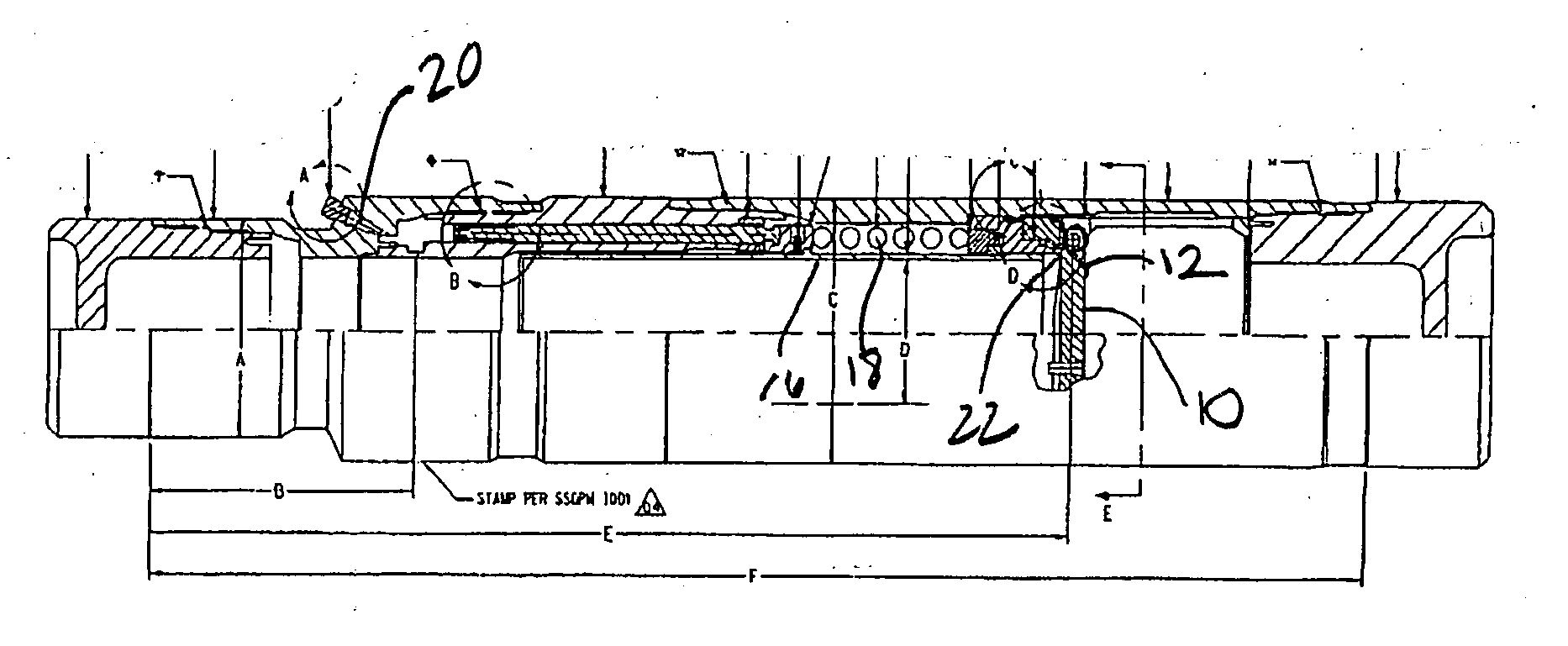

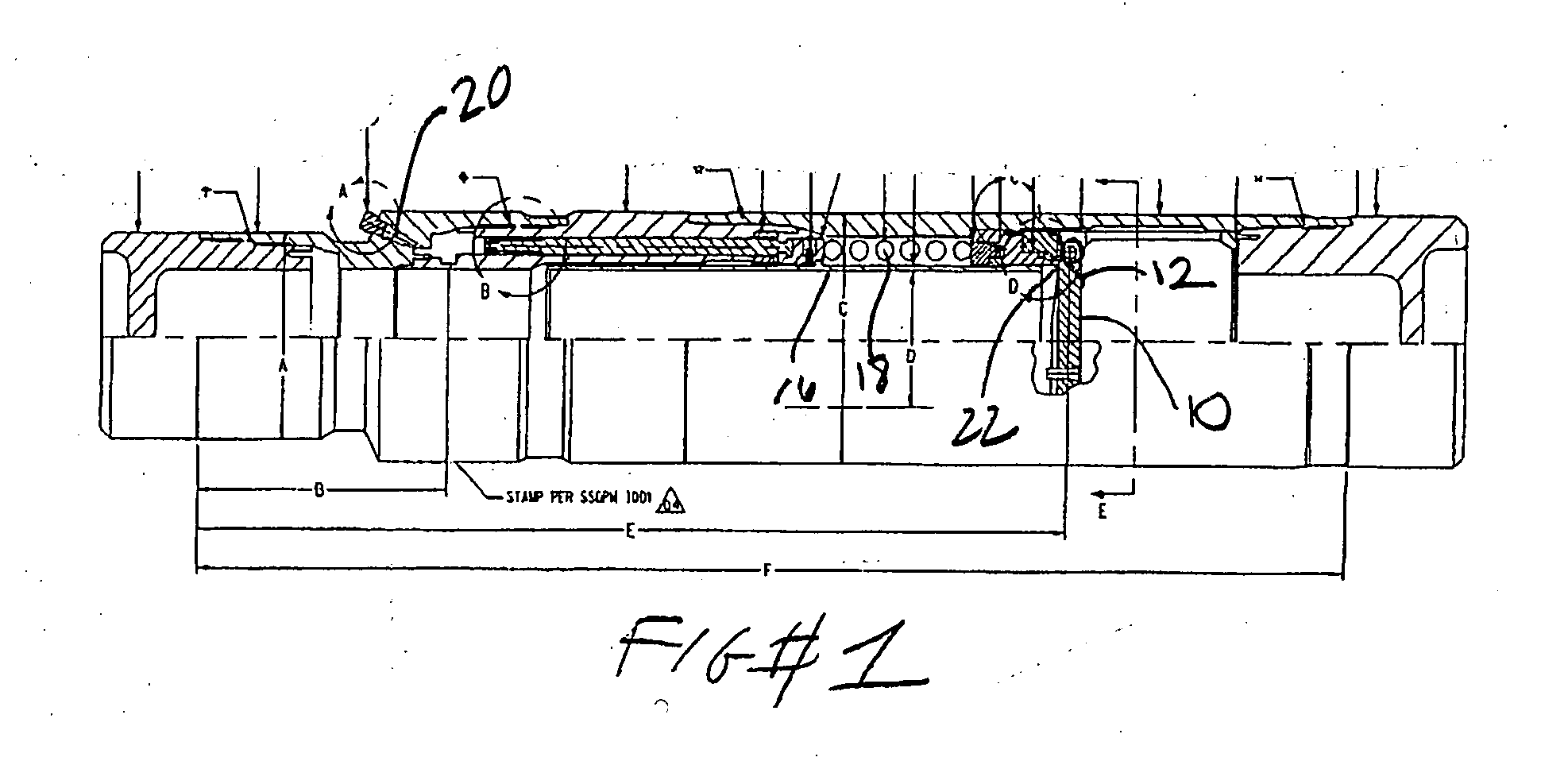

[0015]FIG. 1 shows a subsurface safety valve, SSV, in the closed position. A flapper 10 is pivoted closed by a coiled spring 12 against a seat 14 when the flow tube 16 is raised by closure spring 18 upon failure of pressure at control line connection 20. FIG. 1 illustrates a known SSV. The invention lies in the manner of producing the components, particularly the flapper 10 and its associated seat 22. The preferred material is a nickel 718 alloy and it is preferably cast and HIPped and then subjected to finish machining to get the component to its dimensional tolerances. The HIPping reduces porosity and increases strength and improves corrosion resistance. While the flapper can be produced by this technique with a resultant cost savings of nearly 70% over machining the part from bar stock, it will be understood that other components of the SSV such as the seat 22 or the flow tube 16 or other parts can be made from the same casting and HIPping technique. While the preferred material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dimension | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com