Self-cleaning flooring system

a self-cleaning and flooring technology, applied in the field of flooring protection, can solve the problems of difficult if not impossible maintenance of cleanliness, frequent spillage of waste products on kitchen flooring in restaurants, hotels, commercial food vending facilities in general, and the lik

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

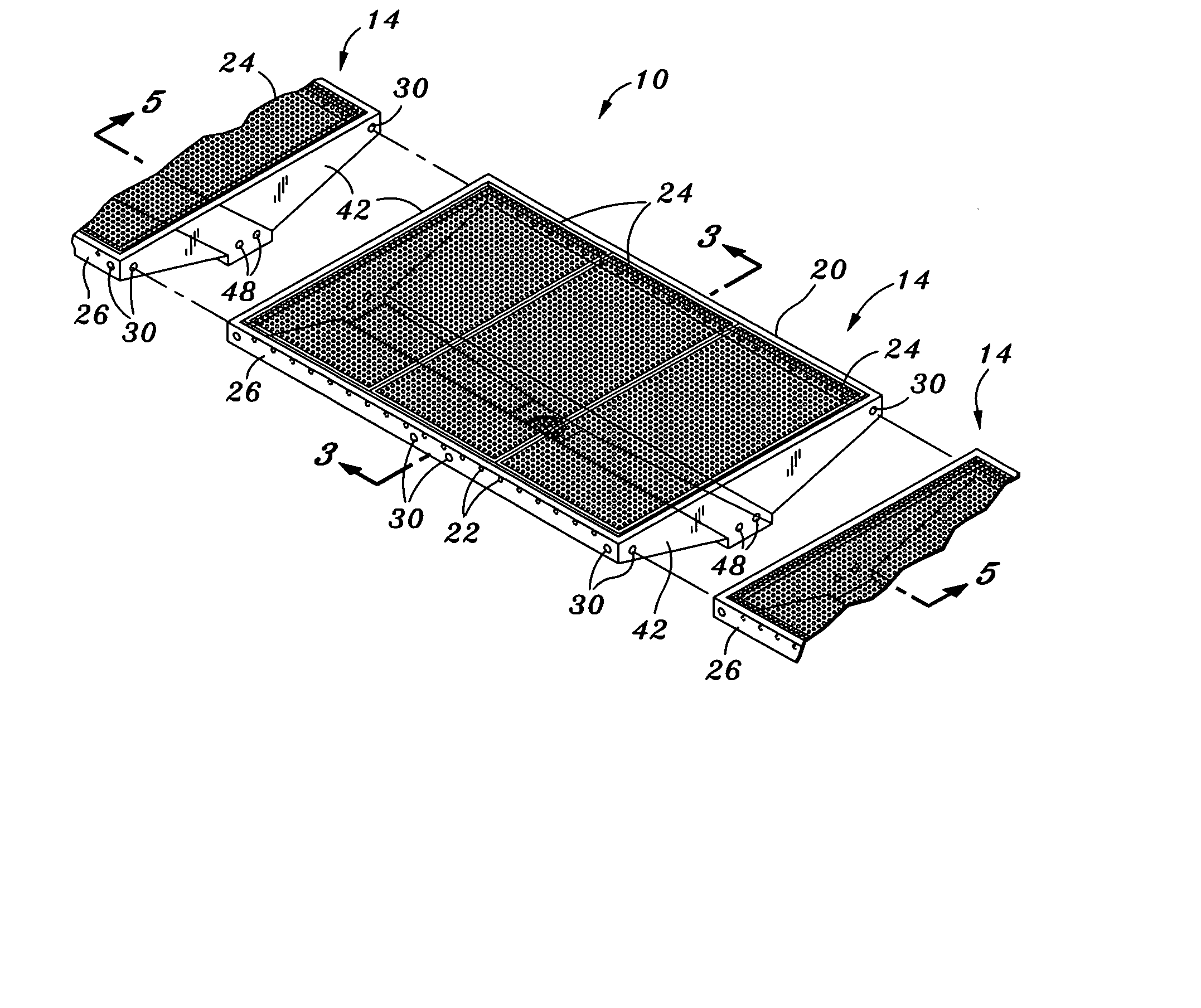

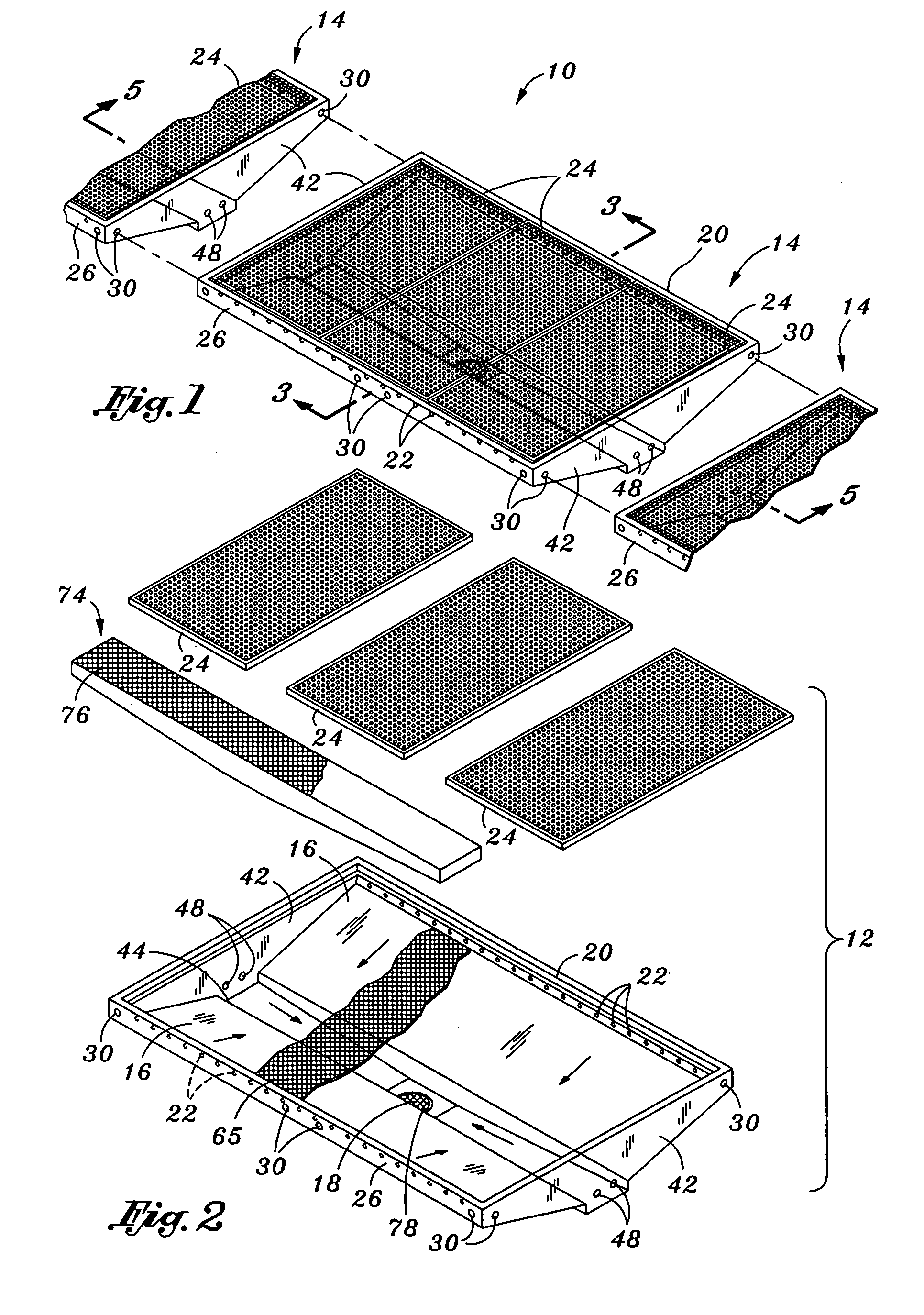

first embodiment

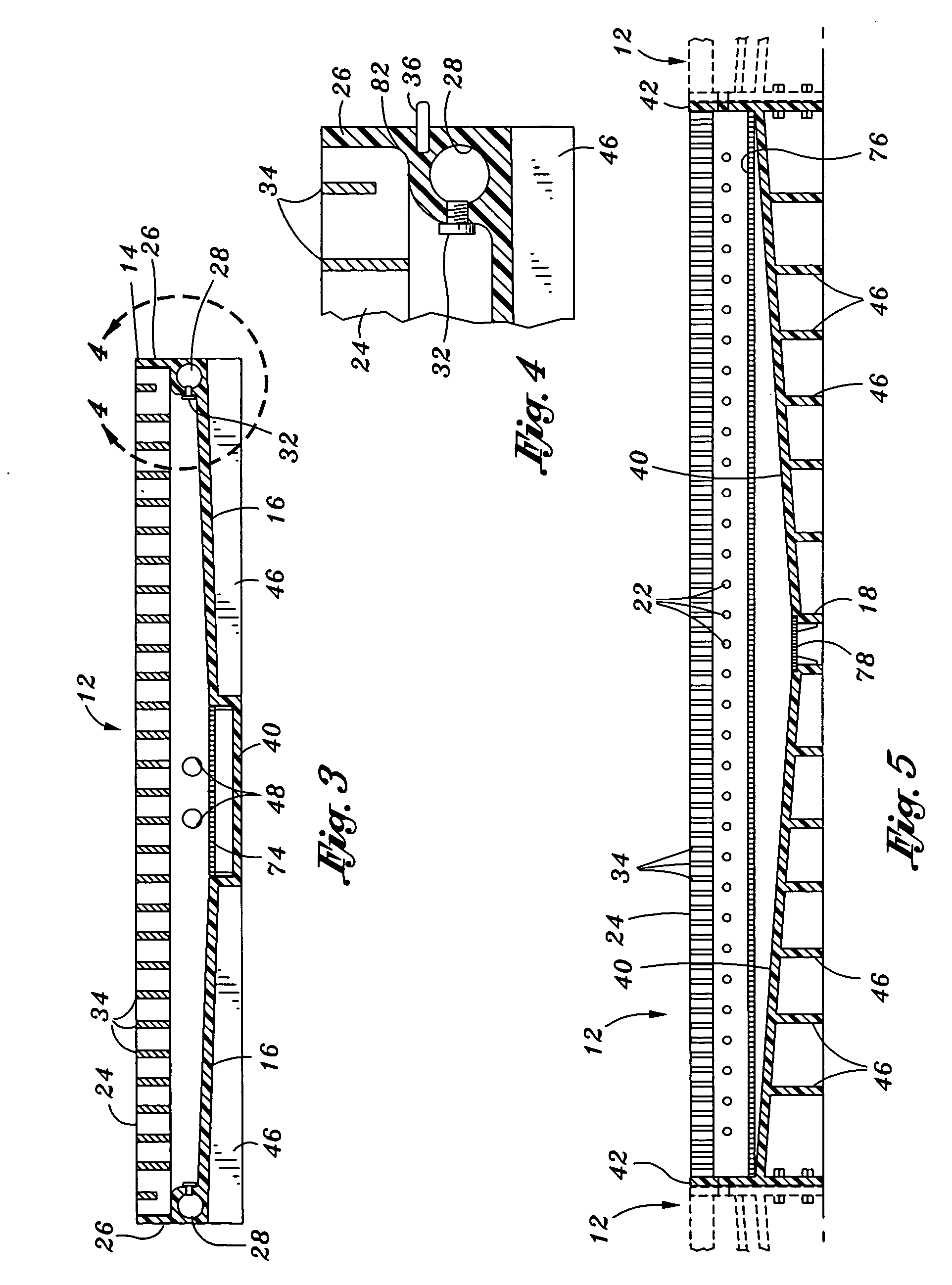

[0062] Turning now to FIG. 5, shown in a transverse sectional view of the module 12 of the first embodiment taken along line 5-5 of FIG. 1 and illustrating the drain channel 40 sloping downwardly toward the drain outlet 18. In FIG. 5, the rib members 46 can be seen extending vertically downwardly from the ramp 16 lower surface. Discharge ports 22 can be seen disposed within the side wall 26 and extending along the length thereof. The discharge ports 22 may be evenly spaced between the end walls 42 although any spacing is contemplated for the discharge ports 22.

[0063] The strainer tray 74 is shown disposed above or mounted within the drain channel 40 which extends from end wall 42 to end wall 42. As was earlier mentioned, the strainer tray 74 includes a grate 76 which prevents the entry of solid or semisolid waste products into the drain channel 40 which may otherwise fall into the drain outlet 18 resulting in clogging thereof. As a final measure of protection, a removable drain bask...

second embodiment

[0066] Turning now to FIGS. 6 and 7, shown is a self-cleaning flooring system 10 which, as was earlier mentioned, comprises at least one module 12, but preferably comprises a series of modules 12 joined end-to-end. Each one of the modules 12 comprises a drain pan section 66 which is itself comprised of a pair of first and second ramp sections 50, 52, and a channel section 54 which is disposed between the first and second ramp sections 50, 52. As shown in FIGS. 6 and 7, the first ramp section 50 is joined to the second ramp section 52 which is interconnected to the channel section 54. The channel section 54 is preferably configured to removably interconnect the first and second ramp sections 50, 52 together at a lower side portion 58 of each one of the first and second ramp sections 50, 52.

[0067] As was mentioned for the configuration in FIGS. 1-5, the first and second ramp sections 50, 52 slope downwardly toward the channel section 54. The module 12 shown in FIGS. 6 and 7 is also co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com