Controller for suppressing temperature of screen

a technology of controller and screen, which is applied in the direction of static indicating devices, instruments, gas-filled discharge tubes, etc., can solve the problems of increased production, inability to effectively disperse heat produced, and affecting the service life of all electronic components and the liquid crystal display panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] To make it easier for our examiner to understand the objective of the invention, its structure, innovative features, and performance, we use a preferred embodiment and the attached drawings for the detailed description of the invention.

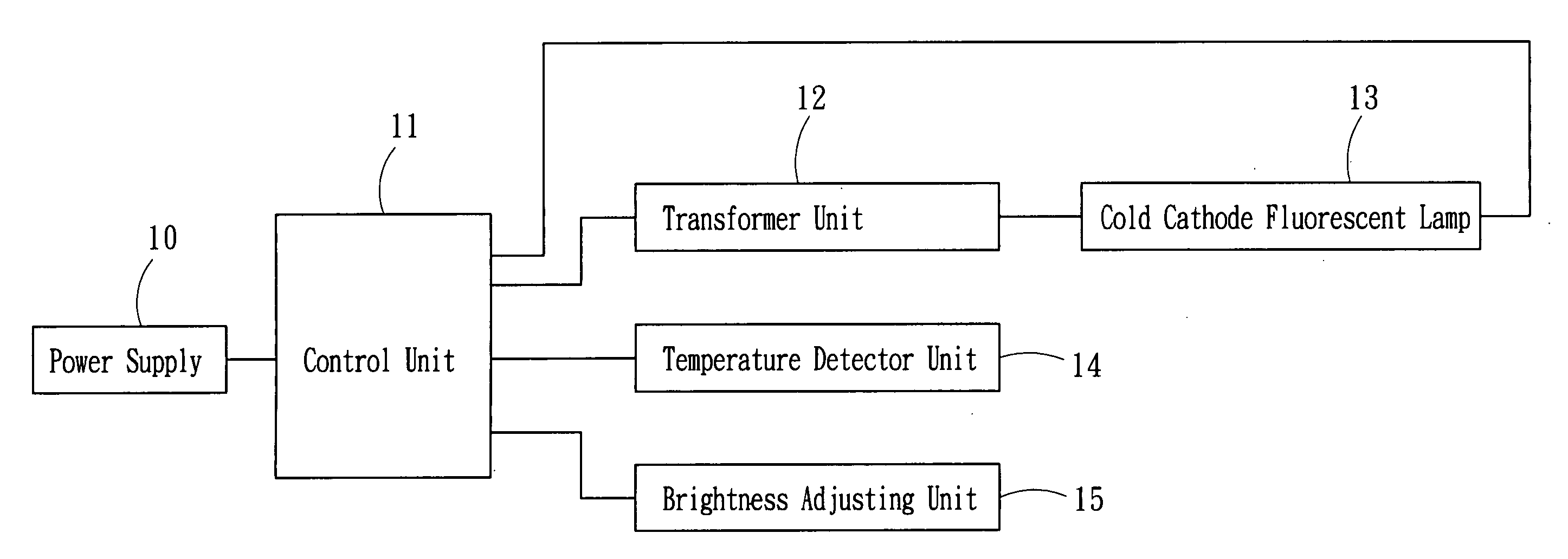

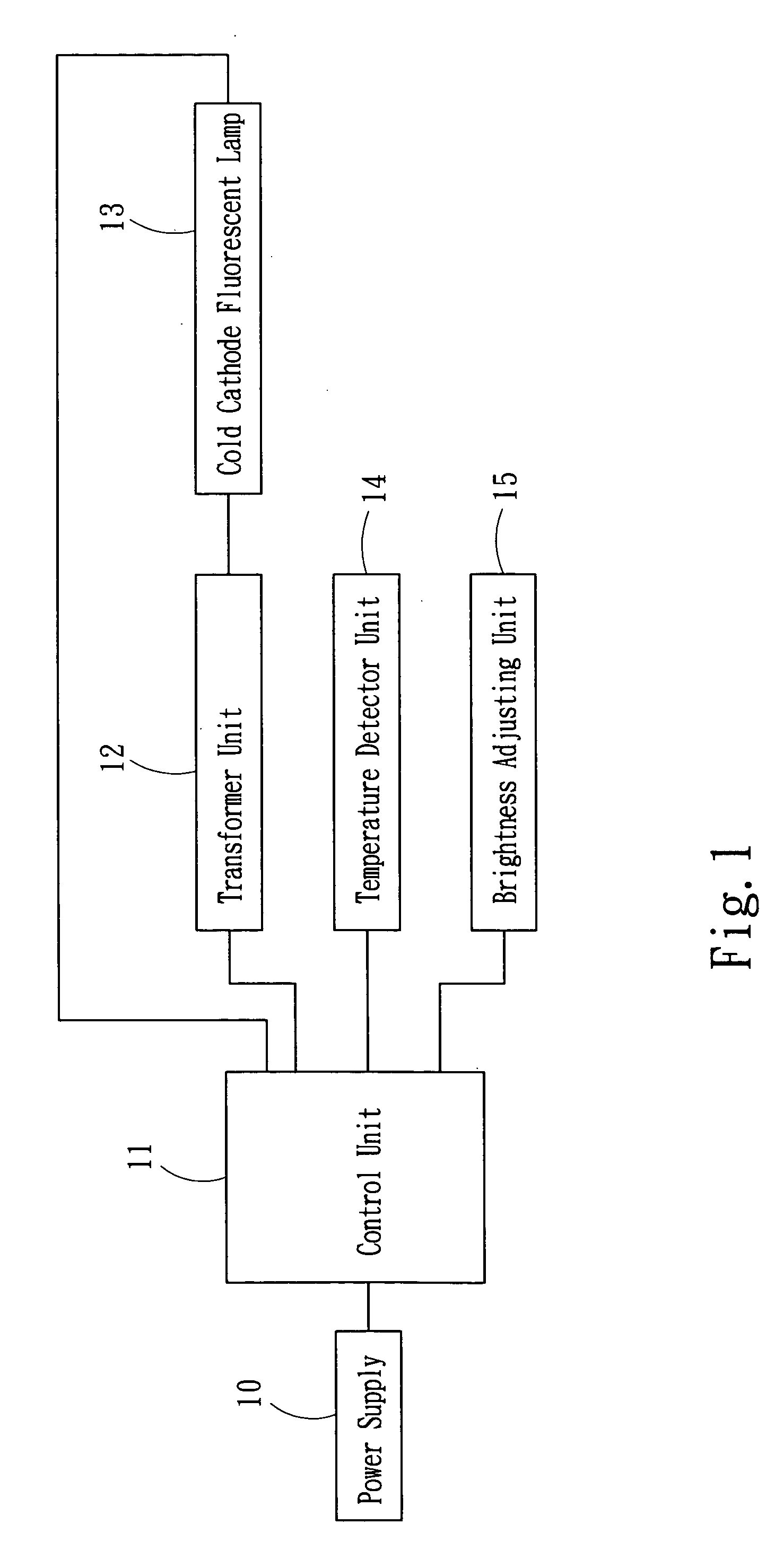

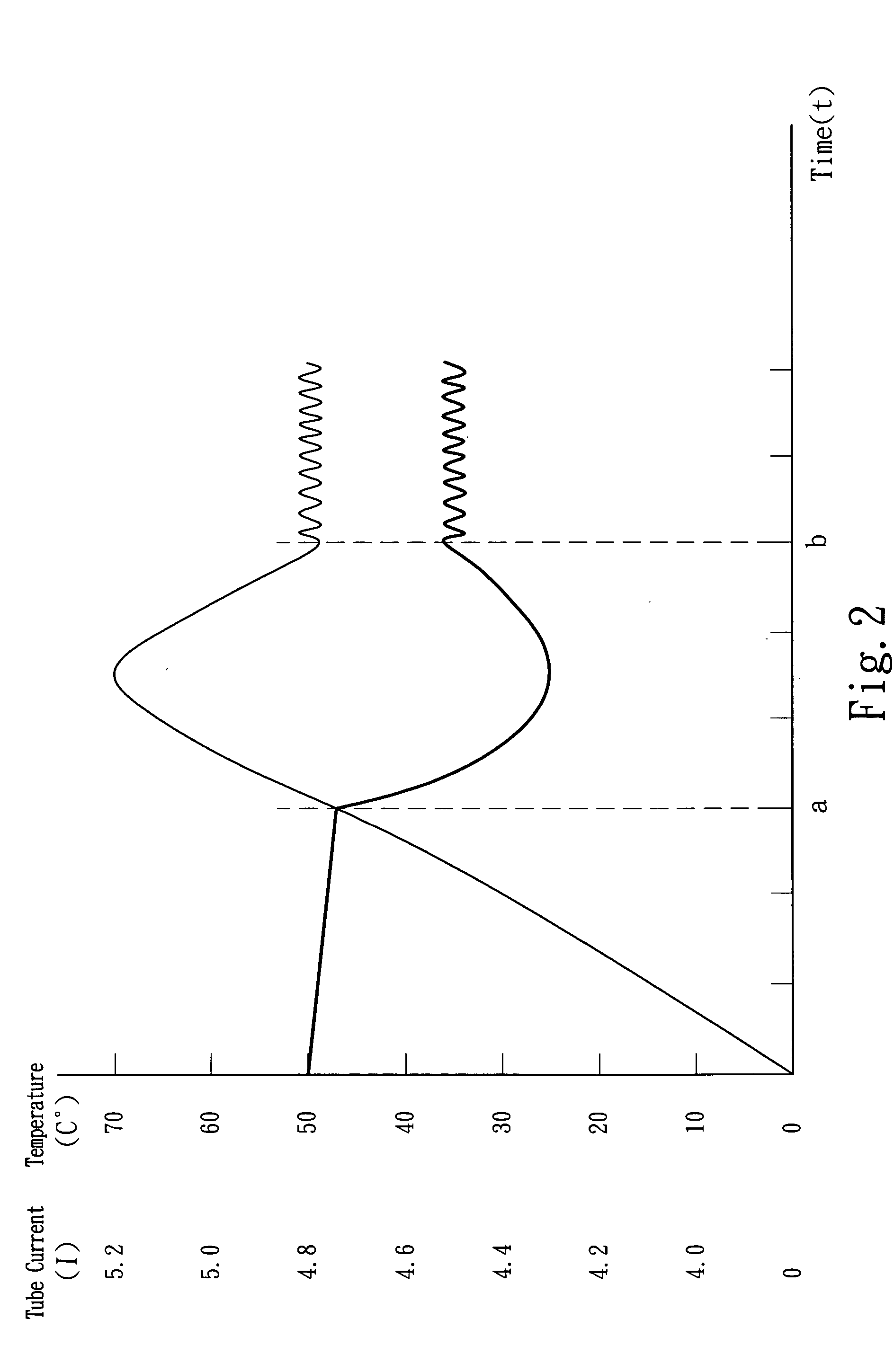

[0009] Please refer to FIG. 1 for the circuit block diagram of the present invention. In FIG. 1, the screen according to the present invention comprises a power supply 10 connected with an output power signal, and the power supply 10 refers to the device converting the alternate current into a direct current and outputting the direct current as a direct current power signal or a pulse direct current power signal. The power signal outputted from the power supply 10 is outputted to a control unit 11, and the control unit 11 according to the present existing technology comprises a pulse width modulator (PWM) and a MOS power transistor or a waveform generator and a signal amplifier. The control unit 11 is used for outputting a drive signal and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com