Versatile system for output energy limiting circuitry

a technology of output energy limiting circuitry and reverse circuitry, which is applied in the direction of pulse generator, power consumption reduction, pulse technique, etc., can solve the problems of reducing the efficiency of driver circuitry, reducing the efficiency of device and system inefficiency, and generating numerous challenges to the semiconductor manufacturing process. , to achieve the effect of limiting output energy levels, reducing device and system inefficiencies, and efficient and reliable device performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

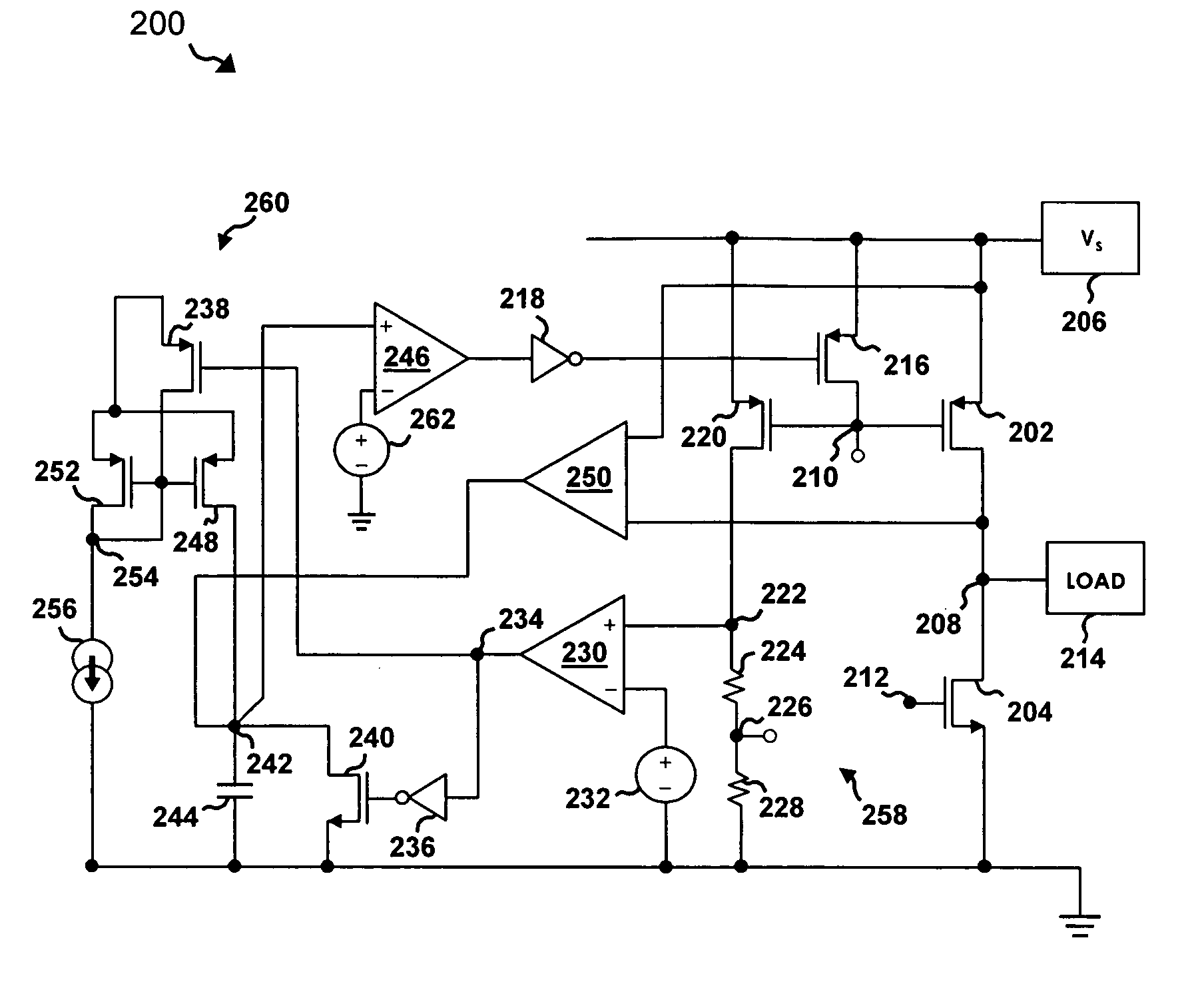

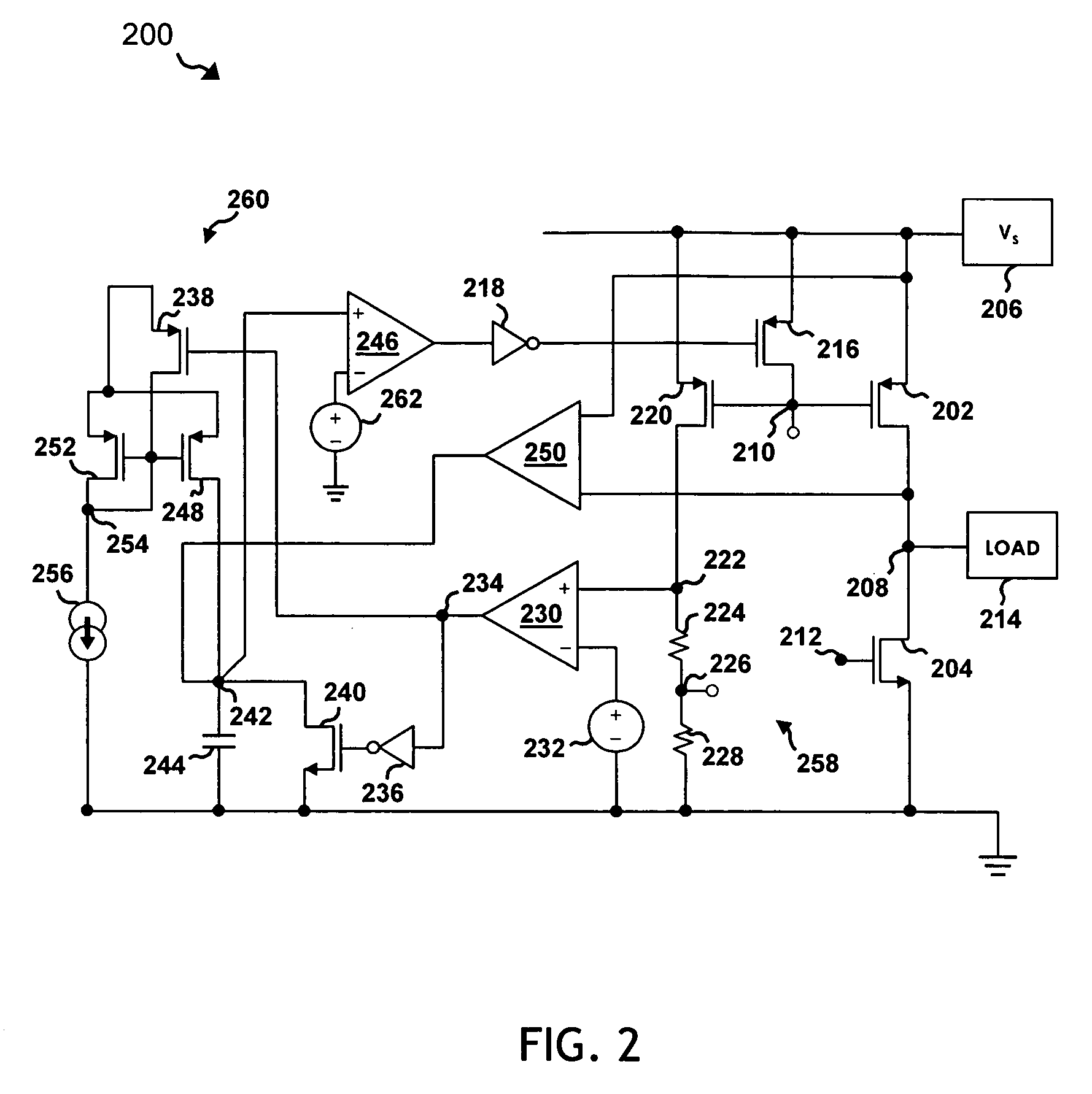

[0023] While the making and using of various embodiments of the present invention are discussed in detail below, it should be appreciated that the present invention provides many applicable inventive concepts, which can be embodied in a wide variety of specific contexts. The present invention is hereafter illustratively described primarily in conjunction with the design and operation of driver circuitry in the form an operational amplifier. Certain aspects of the present invention are further detailed in relation to design and operation of circuitry utilizing a PMOS transistor within a CMOS semiconductor process. Although described in relation to such structures, the teachings and embodiments of the present invention may be beneficially implemented with a variety of semiconductor devices or structures (e.g., NMOS transistors, low / high side driver systems). The specific embodiments discussed herein are, therefore, merely demonstrative of specific ways to make and use the invention an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com