Phacoemulsification machine with post-occlusion surge control system and related method

a technology of surge control and phacoemulsification machine, which is applied in the direction of machines/engines, flexible member pumps, and positive displacement liquid engines, etc., can solve the problems of increasing the probe temperature, reducing the flow rate, and adding resistance to the aspiration tube, so as to reduce the post-occlusion surge and reduce the effect of surg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

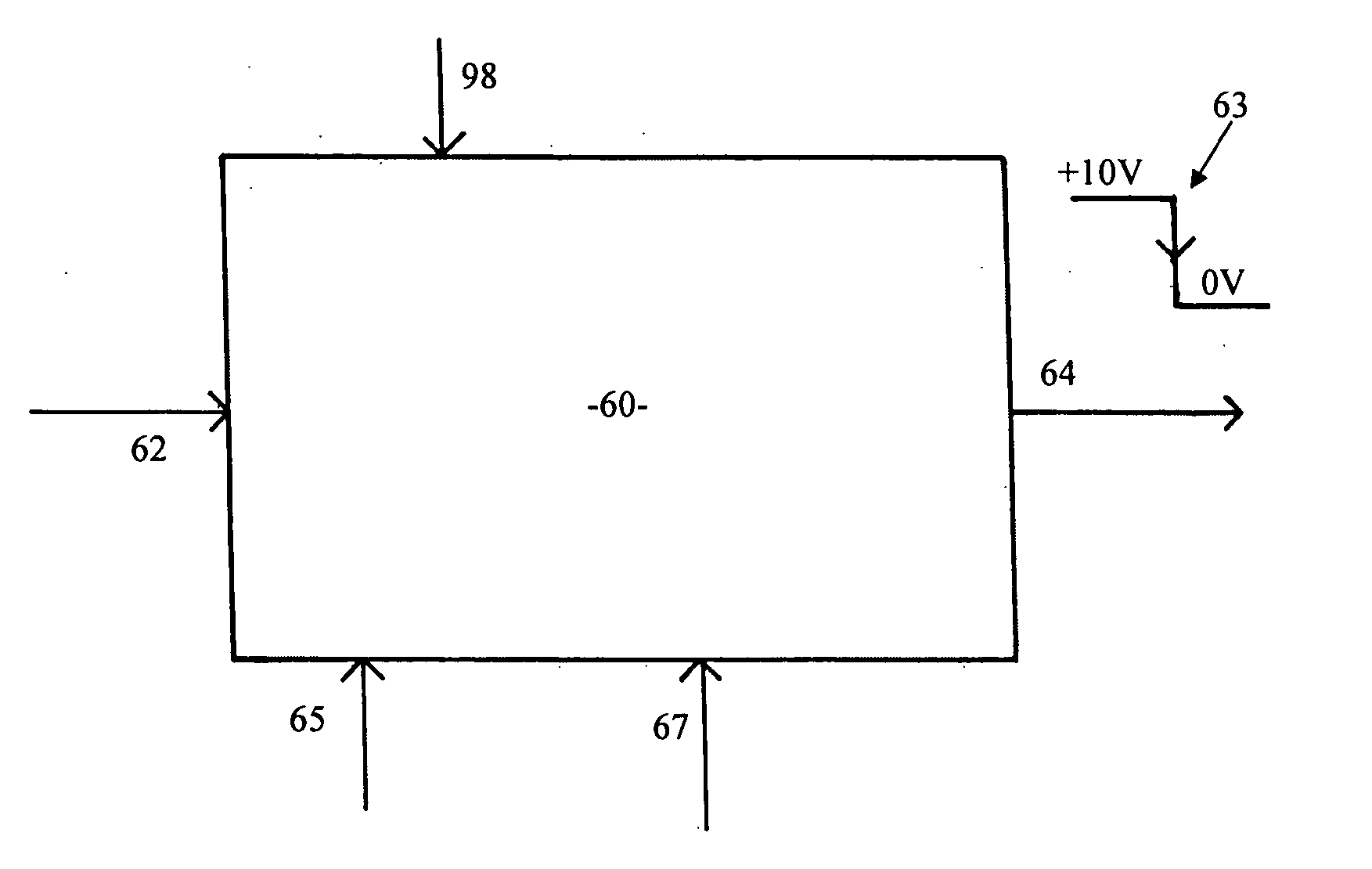

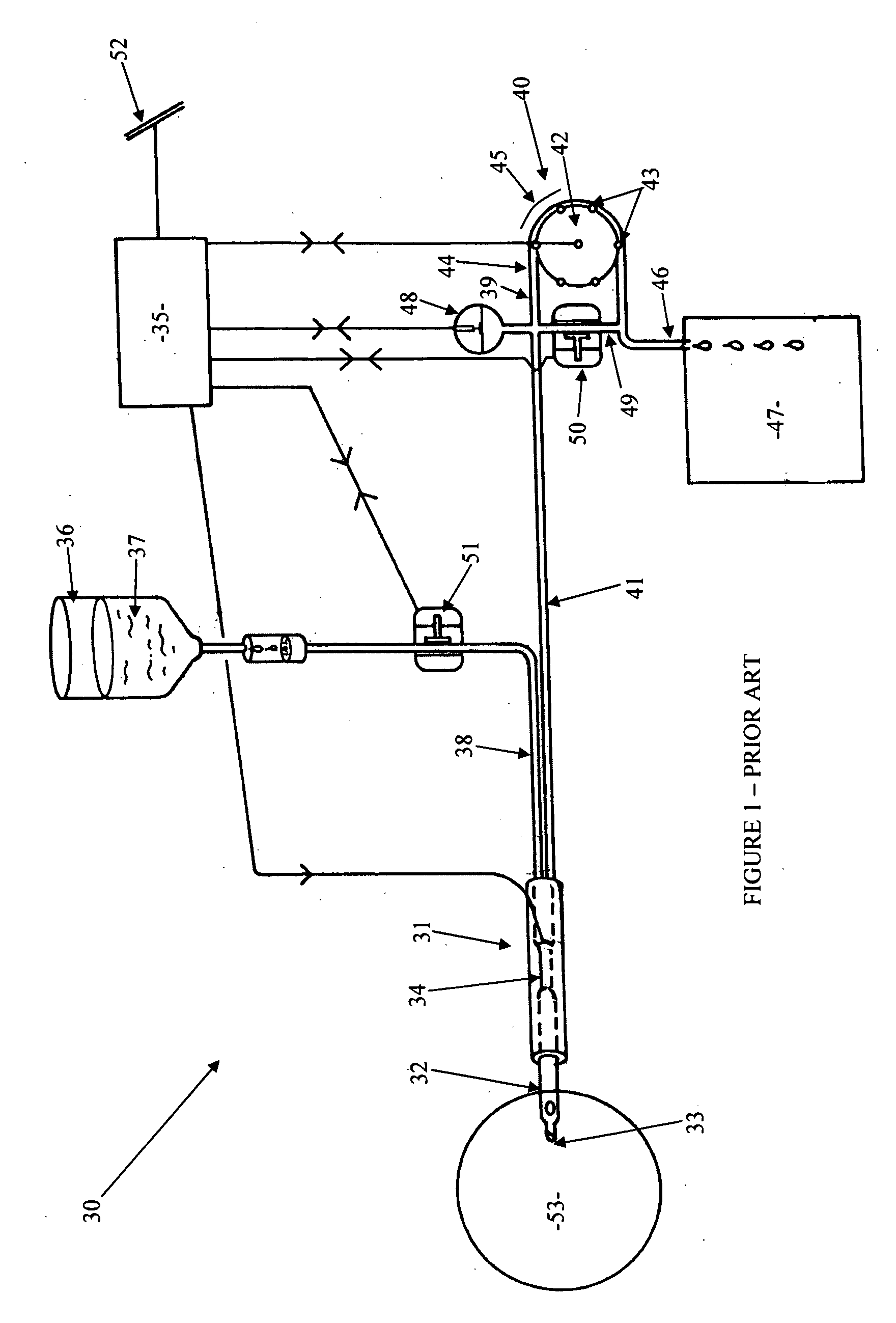

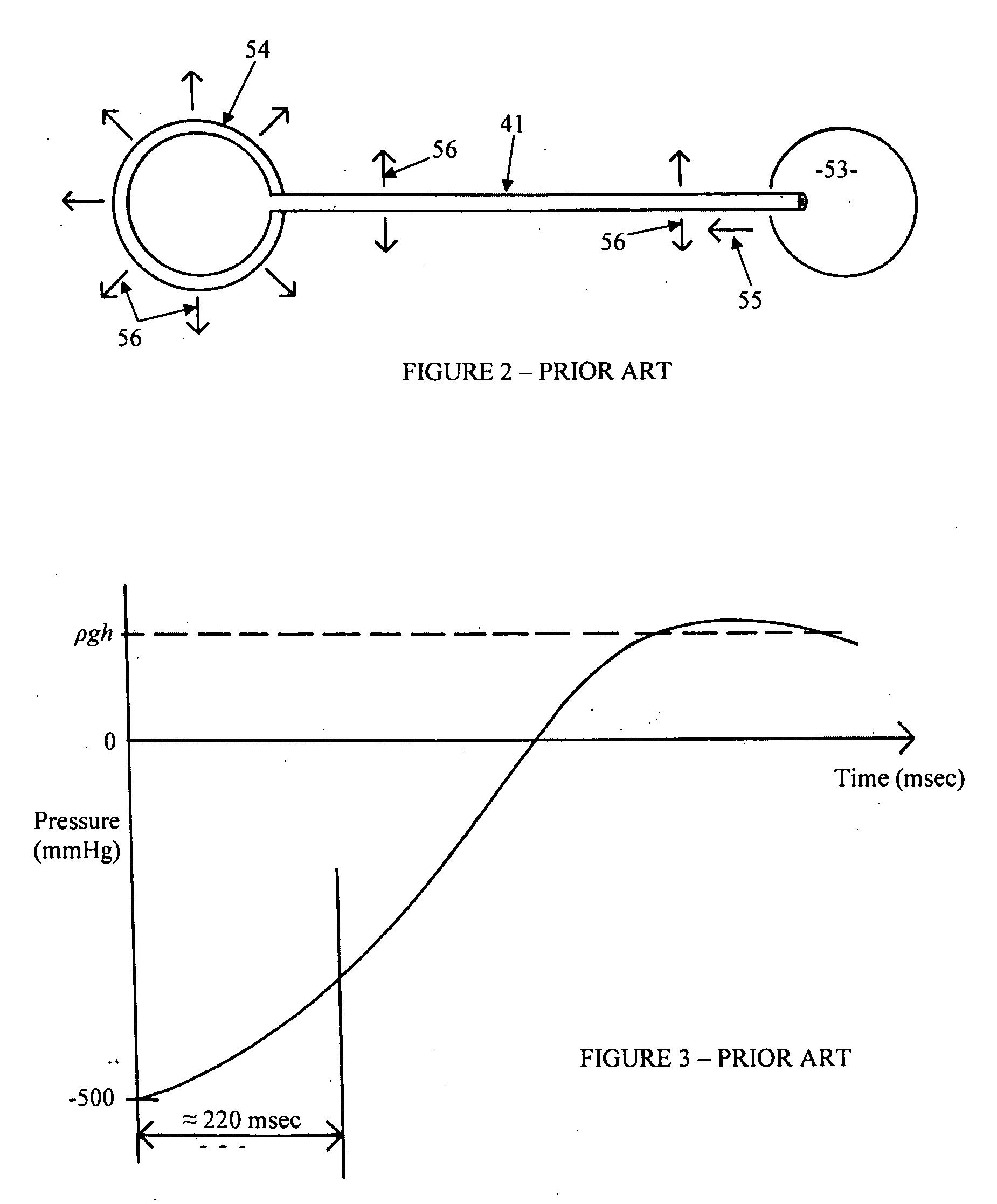

[0064] The prior art phaco-machine 30 depicted in FIG. 1 can be modified to include a post-occlusion surge controller which includes a post-occlusion surge detector 60 which is depicted in FIG. 6, and a valve controller 61 which is depicted in FIG. 7.

[0065] The post-occlusion surge detector 60 includes a vacuum sensor input 62 for connecting the detector 60 to the output of the vacuum sensor 48 of the phaco-machine 30 so that the electrical signal which is output by the sensor 48 can be monitored and processed by the detector 60. The electrical signal which is output by the sensor 48 is a positive voltage which is proportional to the vacuum in the interconnected compliant components of the machine 30 which is sensed by the sensor 48. The output of the vacuum sensor 48 may, for example, be 10V / 500 mmHg vacuum.

[0066] The detector 60 may include, for example, an operational amplifier configured as a differentiation amplifier, or a microcontroller. The detector 60 is configured to dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com