Hot gas quenching devices, and hot gas heat treating system

a technology of quenching device and hot gas, which is applied in the direction of heating stove, blast furnace components, blast furnaces, etc., can solve the problems of increasing the scale of the plant and the cost of the products, affecting the quality of the product, so as to achieve sequential and efficient heat treatment, wide range of adaptability, and not deteriorate the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

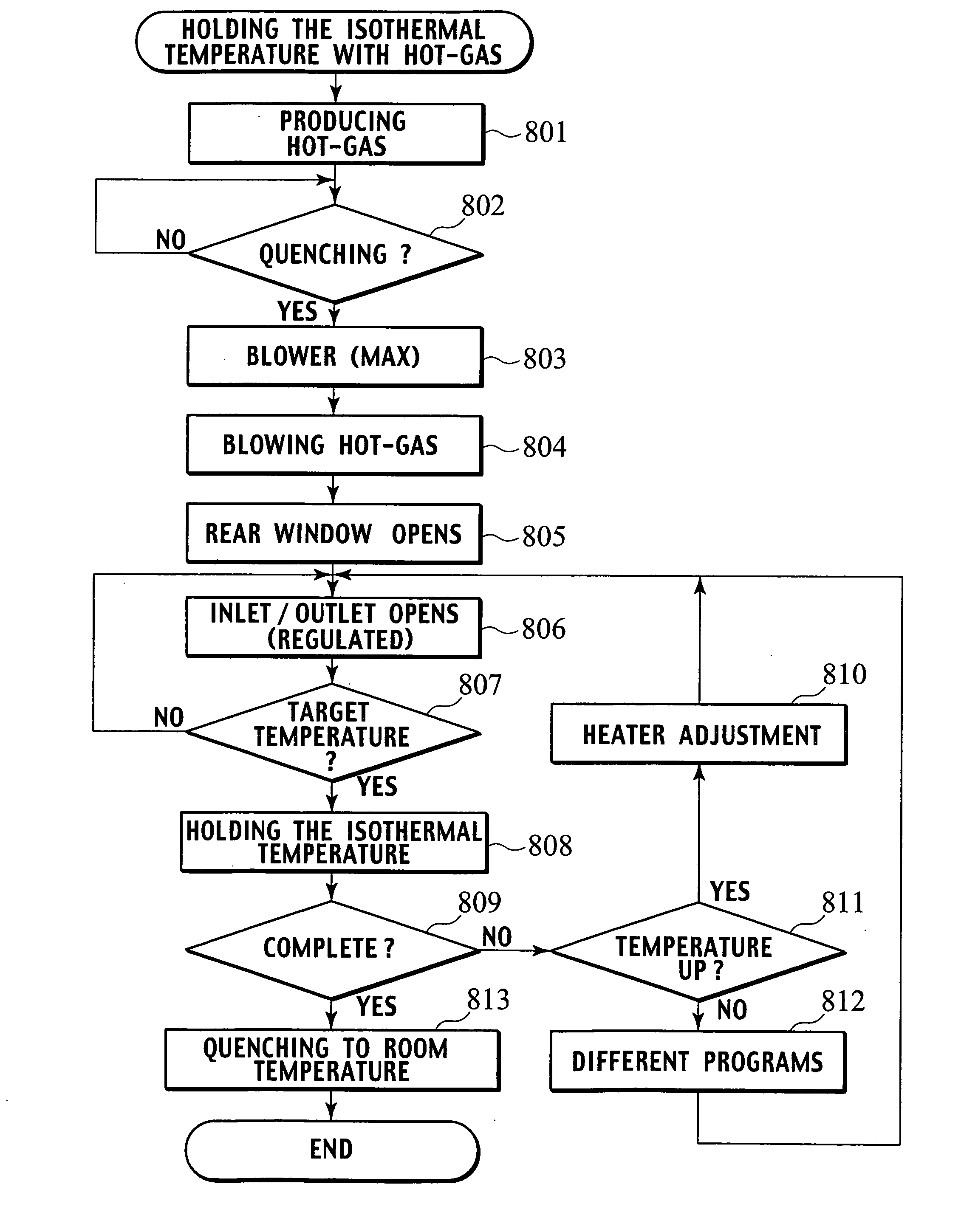

[0066] With regard to hot-gas quenching apparatuses H•O•T-i (i=1 to 5) and a hot-gas heat treatment system H•O•T•S according to the present invention, embodiments will be described sequentially with reference to attached drawings.

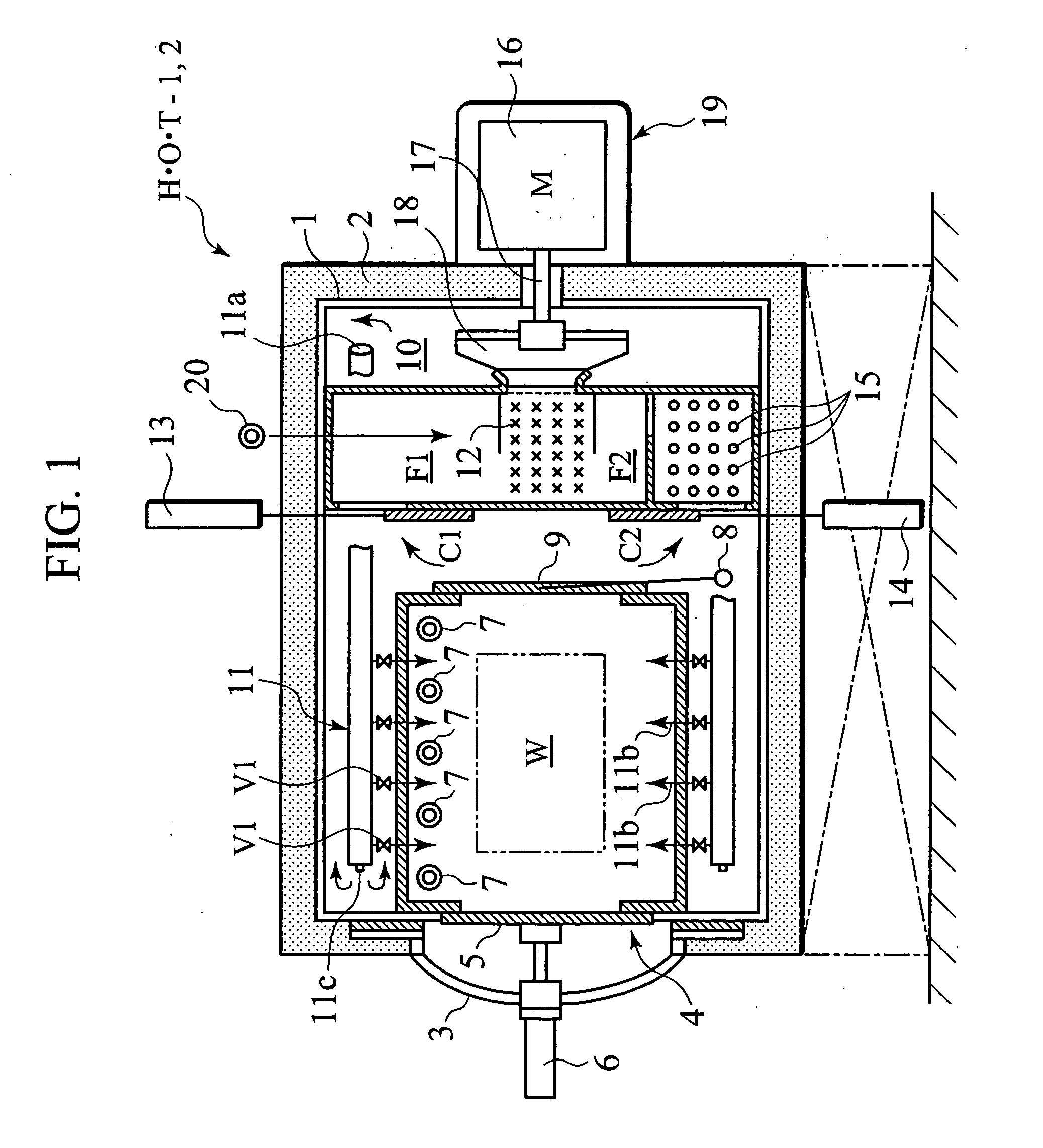

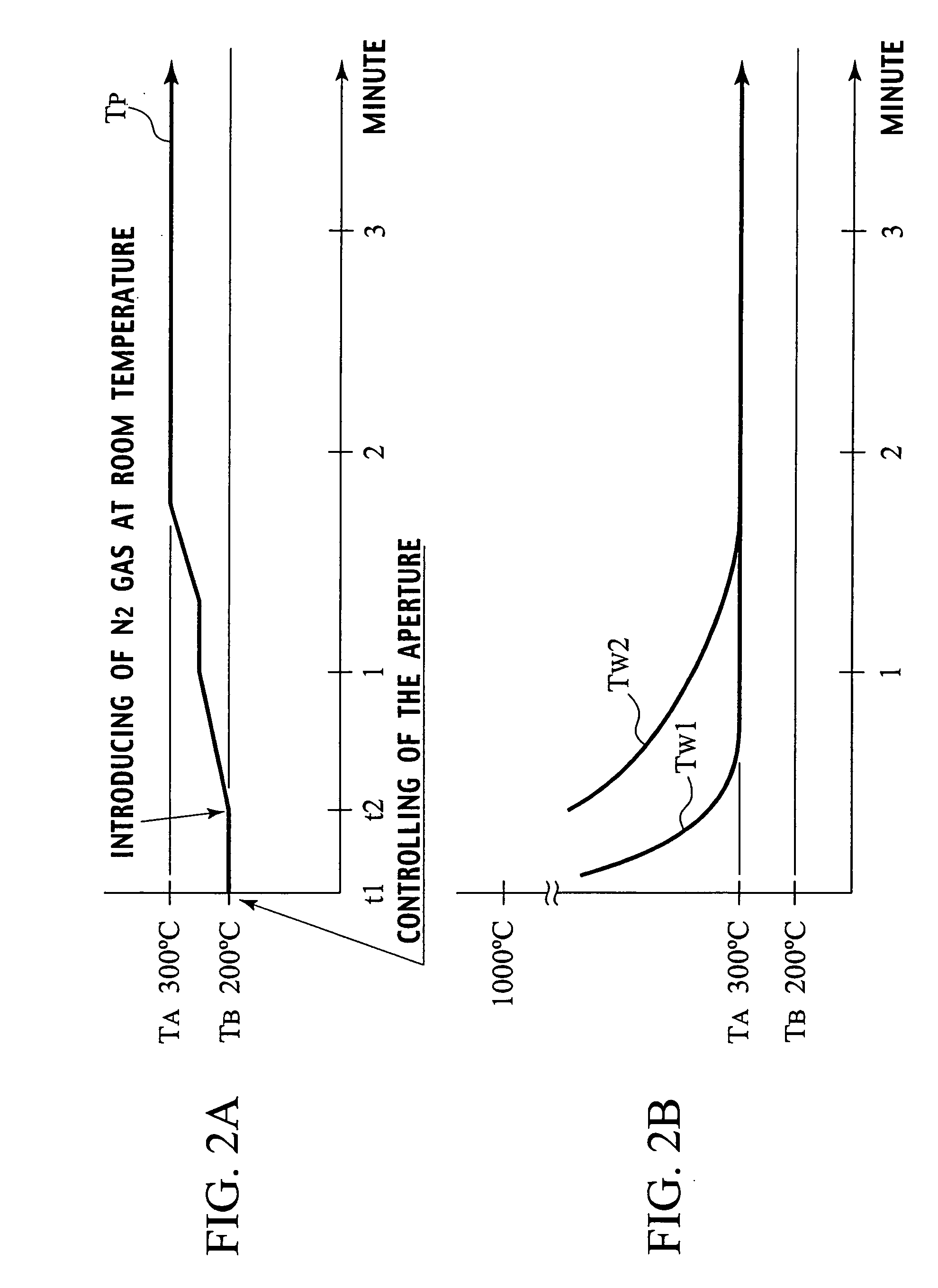

[0067] A structure of hot-gas quenching apparatuses H•O•T-1 and H•O•T-2 according to an embodiment of the present invention is shown in FIG. 1. The hot-gas quenching apparatus of basic type H•O•T-1 and the hot-gas quenching apparatus of gas-preheated type H•O•T-2 look the same. Positions into which inert gas (N2 gas) is introduced and control methods are different between the two hot-gas quenching apparatuses. With regard to the hot-gas quenching apparatus of basic type H•O•T-1, positions into which inert gas is introduced may be any of first and second ducts. However, with regard to the hot-gas quenching apparatus of gas-preheated type H•O•T-2, a position into which inert gas is introduced should be the first duct. The figure is shown citing an example of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| isothermal holding temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com