Process of rapidly preparing a fermented dry or semi-dry sausage product and products therefrom

a technology of fast preparation and fermented products, which is applied in the field of fast preparation of fermented dry or semi-dry sausage products and products therefrom, can solve the problems of slow fermentation using this method, increase the overall cost, and slow availability of such ingredients to the manufacturer, so as to reduce the processing time, reduce the time frame, and reduce the effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

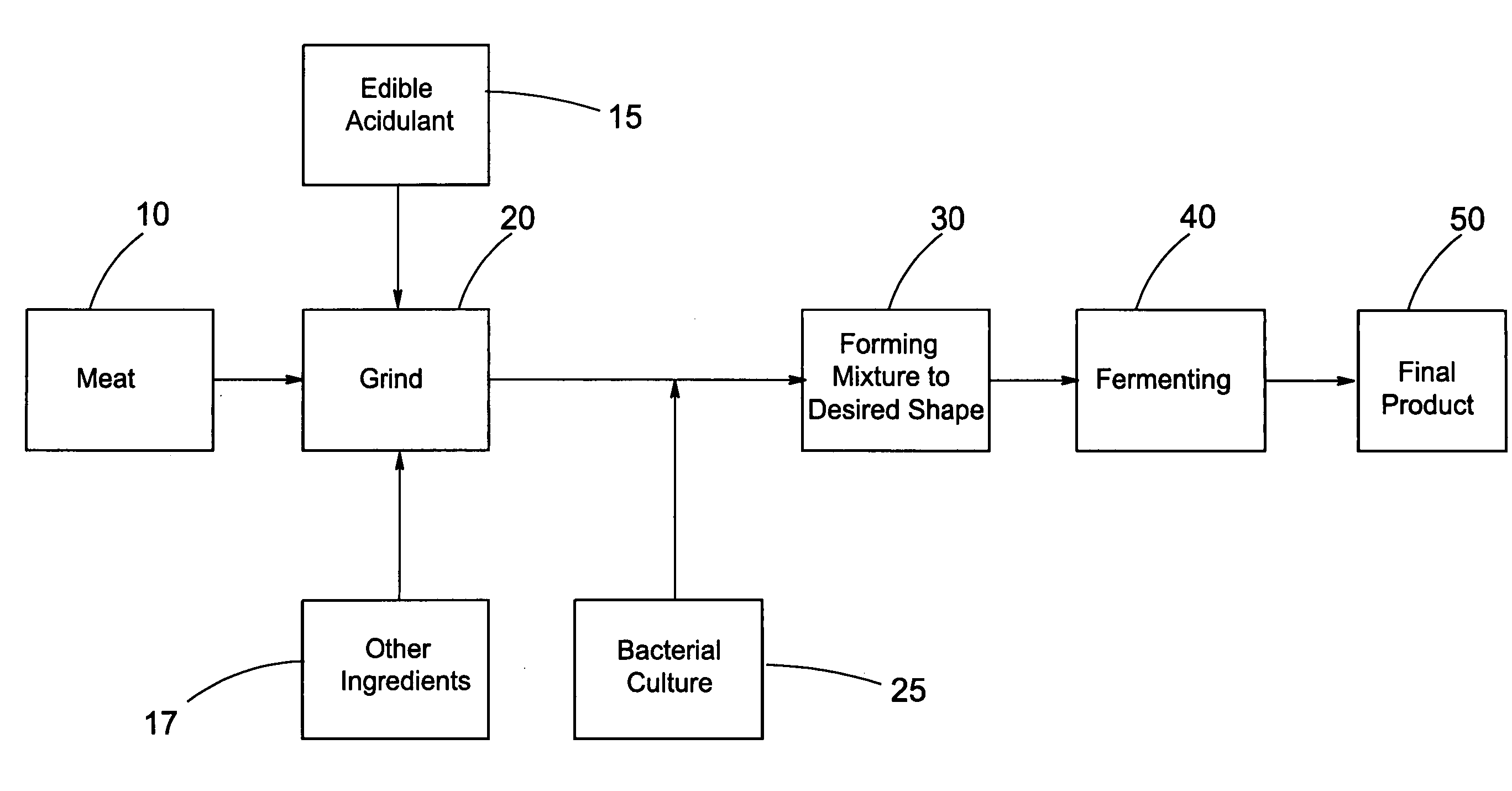

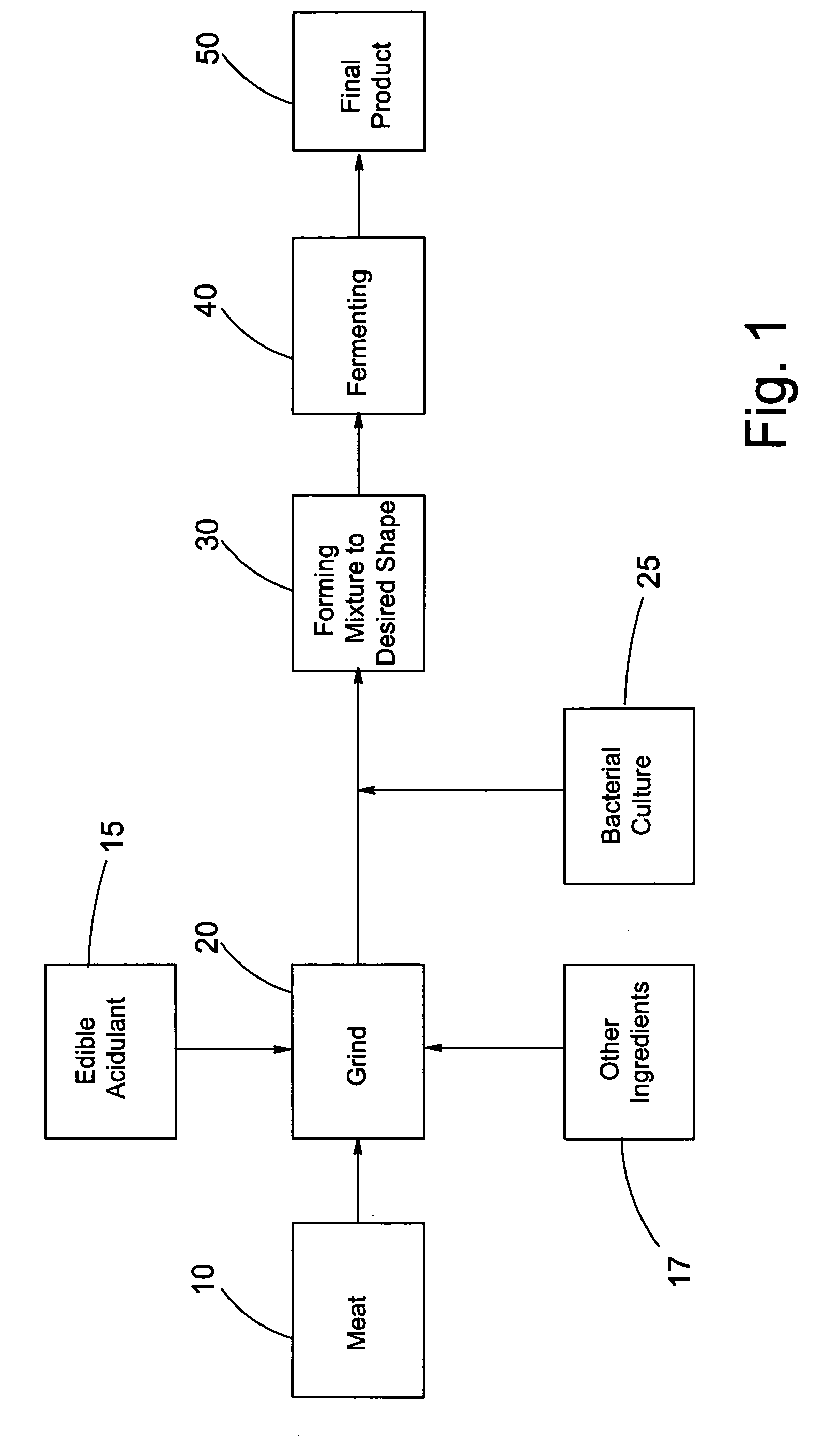

Method used

Image

Examples

example 1

[0044] A sample of dry sausage (pepperoni) was produced in accordance with the inventive process.

[0045] First, the meat, approximately 5 kg, was ground and then admixed with the slow release acidulant, glucanodelta-lactone (GDL) approximately 0.5% by weight of the ground meat. Dextrose is added to the meat mixture. Additional spices, seasonings, a curing agent and a protein source may be added to form a sausage admixture. The meat consisted of a mix of beef and pork in a range of approximately 30% beef and 70% pork. The beef and pork were ground together in a conventional meat grinder prior to being admixed with the other ingredients. The total fat content in the meat was about 35% by weight based on the weight of the meat (meat referring to the meat mix).

[0046] The spices and seasonings used were conventional sausage or Italian seasonings obtained from Chris Hanson Corp. and included approximately 5% by weight of the batch prepared.

[0047] Next, a bacterial culture selected from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com