Liquid crystal orientating agent and liquid crystal display element using it

a technology of orientating agent and liquid crystal, which is applied in the direction of chemistry apparatus and processes, instruments, transportation and packaging, etc., can solve the problems of display failure, difficult to satisfy all the required characteristics only with conventional techniques, and persistence of displayed images, etc., to achieve excellent liquid crystal alignment properties, reduce charge accumulation, and high voltage retention characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

Explanation of Abbreviations Used in the Present Examples

Tetracarboxylic Dianhydrides

[0088] TC-1: 1,2,3,4-cyclobutanetetracarboxylic dianhydride

[0089] TC-2: 3,4-dicarboxy-1,2,3,4-tetrahydro-1-naphthalenesuccinic dianhydride

[0090] TC-3: 1,2,3,4-butanetetracarboxylic dianhydride

[0091] TC-4: bicyclo[3,3,0]octane-2,4,6,8-tetracarboxylic dianhydride

[0092] TC-5: pyromellitic dianhydride

Diamines

[0093] DA-1: 4,4′-diaminodiphenylamine

[0094] DA-2: 3,6-diaminocarbazole

[0095] DA-3: 4,4′-diaminodiphenylmethane

[0096] DA-4: 1,3-bis(4-aminophenoxy)benzene

[0097] DA-5: di(4-aminophenyl)butane-1,4-dioate

[0098] DA-6: 1,5-bis(4-aminophenoxy)pentane

[0099] DA-7: 1,8-bis(4-aminophenoxy)octane

[0100] DA-8: 1,5-bis[4-(4-aminophenoxy)phenoxy]pentane

[0101] DA-9: 1,6-bis[4-(4-aminophenoxy)phenoxy]hexane

[0102] DA-10: 4,4′-diamino-p-terphenyl

[0103] DA-11: paraphenylenediamine

[0104] DA-12: 4,4′-diaminodiphenyl ether

[0105] DA-13: 1,3-diamino-4-octadecyloxybenzene

Organic Solvents

[0106] NMP: N...

preparation examples

Preparation of Specific Polymer a

preparation example 1

[0109] 18.73 g (0.094 mol) of TC-1 and 19.61 g (0.1 mol) of DA-1 were mixed in 345.1 g of NMP and reacted for 5 hours at room temperature to obtain a polyamic acid solution comprising TC-1 / DA-1. The polymerization reaction proceeded easily and uniformly, and the reduced viscosity of the obtained polyamic acid was 1.18 dl / g (at a concentration of 0.5 g / dl, in NMP at 30° C.). Further, this solution was diluted so that it comprised 5 wt % of the polyamic acid, 75 wt % of NMP and 20 wt % of BCS, to obtain a polyamic acid solution (PA-a1).

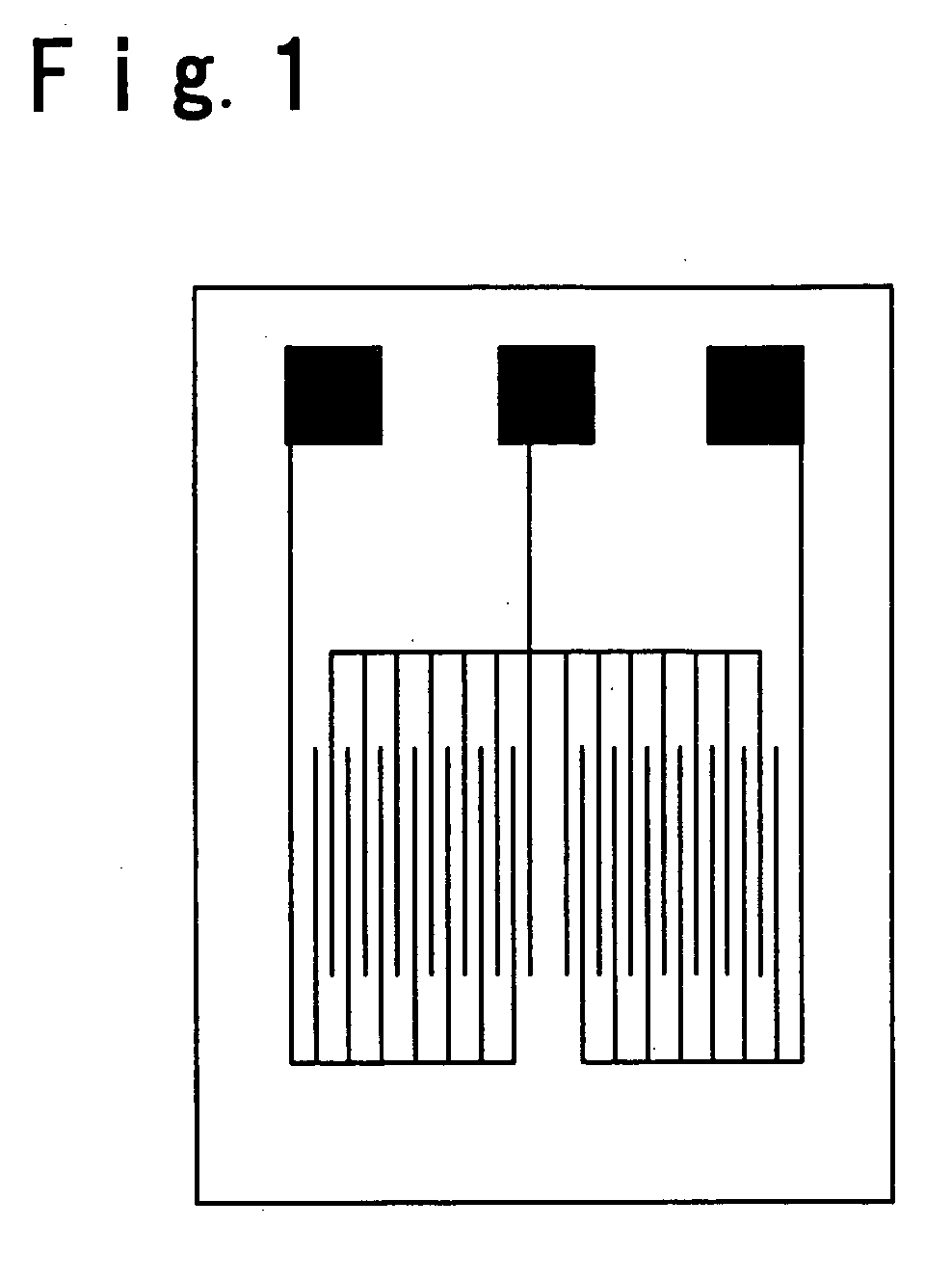

[0110] This polyamic acid solution (PA-a1) was spin-coated on a glass substrate provided with ITO transparent electrodes, dried for 5 minutes on a hotplate of 80° C. and then baked for 30 minutes in a hot air circulation oven at 220° C. to form a coated film having a thickness of 1 μm. Then, aluminum was deposited on the surface of the coated film to form an upper electrode (electrode area 0.0707 cm2). A voltage of 10 V was applied between the ITO elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume resistivity | aaaaa | aaaaa |

| mol % | aaaaa | aaaaa |

| volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com