Liquid crystal alignment agent, liquid crystal alignment film, liquid crystal display element, polymer and compound

A liquid crystal alignment agent, polymer technology, applied in the fields of liquid crystal display elements, liquid crystal alignment agents, polymers and compounds, and liquid crystal alignment films

- Summary

- Abstract

- Description

- Claims

- Application Information

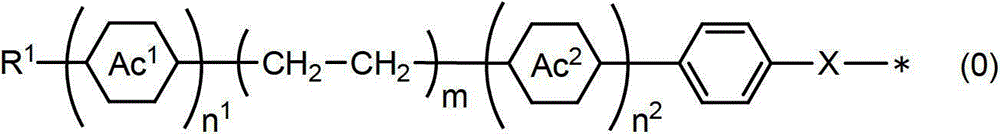

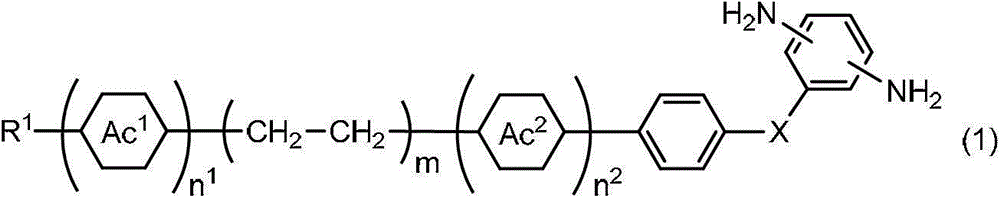

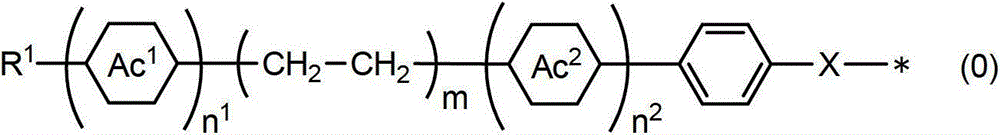

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0163] Hereinafter, the present invention will be further specifically described using examples, but the present invention is not limited by these examples.

[0164] The solution viscosity of each polymer solution in the synthesis example and the imidization rate of polyimide were measured by the following method.

[0165] [Solution Viscosity of Polymer Solution]

[0166] The solution viscosity [mPa·s] of the polymer solution was measured at 25° C. using an E-type rotational viscometer for a solution having a polymer concentration of 10% by weight using a predetermined solvent.

[0167] [Imidation rate of polyimide]

[0168] Put the solution of polyimide into pure water, fully dry the obtained precipitate under reduced pressure at room temperature, dissolve it in deuterated dimethyl sulfoxide, use tetramethylsilane as a reference substance, and determination 1 H-NMR ( 1 H-Nuclear magnetic resonance, 1 H-NMR). according to income 1 From the H-NMR spectrum, the imidizatio...

Synthetic example 1

[0172] [Synthesis Example 1: Synthesis of Compound (D-1)]

[0173] Compound (D-1) was synthesized according to Scheme 1 below.

[0174] [chemical 9]

[0175]

[0176] In a 500mL three-necked flask equipped with a thermometer and a nitrogen introduction tube, add the compound represented by the above formula (1-1-1A) (wherein, the cis-trans isomerism of 1,4-cyclohexylene is trans isomerism respectively Construct) 35.7g, 2,4-dinitrochlorobenzene 20.3g, potassium carbonate 15.2g and N,N-dimethylacetamide 300mL, react at 100°C for 4 hours. After completion of the reaction, 1 L of ethyl acetate, 500 mL of tetrahydrofuran, and 1 L of 1M hydrochloric acid were added to remove the aqueous layer, followed by washing with water three times. Next, magnesium sulfate was added to the organic layer, dried, concentrated, and the precipitated crystals were recovered and dried to obtain 36.6 g of light yellow crystals of the compound represented by the above formula (1-1-1B).

[0177] Ne...

Synthetic example 2

[0178] [Synthesis Example 2: Synthesis of Compound (D-2)]

[0179] Compound (D-2) was synthesized according to Scheme 2 below.

[0180] [chemical 10]

[0181]

[0182] In a 500mL three-neck flask equipped with a dropping funnel, a thermometer, and a nitrogen introduction tube, add the compound represented by the above formula (1-1-1A) (wherein, the cis-trans isomerism of 1,4-cyclohexylene is respectively (trans isomer) 35.7g, tetrahydrofuran 200mL and triethylamine 11.13g, cooled in an ice bath to below 5°C. Next, a solution obtained by dissolving 23.0 g of 3,5-dinitrobenzoyl chloride in 100 mL of tetrahydrofuran was slowly dropped over 30 minutes, and the mixture was returned to room temperature and reacted for 1 hour. After completion of the reaction, add 500 mL of ethyl acetate and 500 mL of 1M hydrochloric acid aqueous solution for liquid separation, and then wash the organic layer with water three times, then dry the organic layer with magnesium sulfate, concentrate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com