Liquid crystal alignment agent, liquid crystal alignment film and method for forming same, liquid crystal display element and compound used for liquid crystal alignment agent

A liquid crystal alignment agent and liquid crystal alignment technology, applied in liquid crystal materials, chemical instruments and methods, organic chemistry, etc., can solve the problems of large cumulative exposure, insufficient sensitivity, etc., achieve high radiation sensitivity, good production efficiency, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0198] Hereinafter, the present invention will be described more specifically by way of examples, but the present invention is not limited by these examples.

[0199]

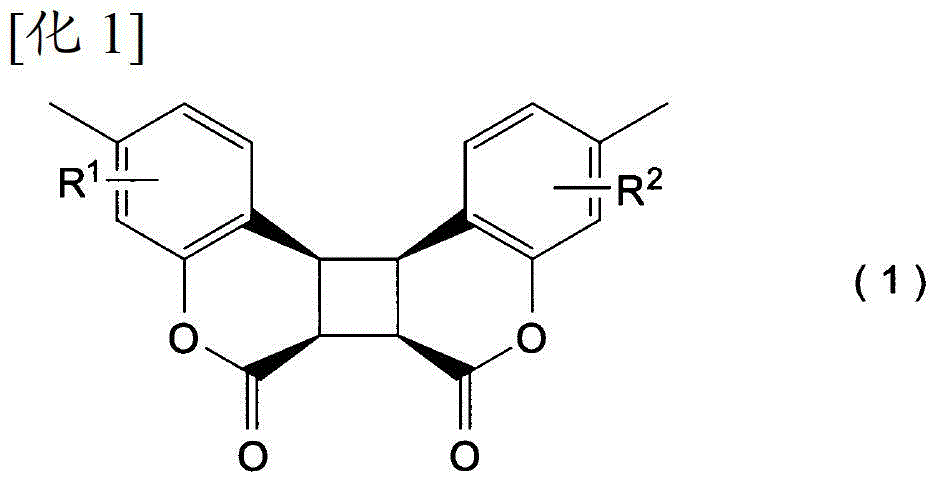

[0200] Compounds represented by the following formulas (B-1) to (B-3) were synthesized according to the following scheme.

[0201] [chemical 7]

[0202]

example 1

[0204] 16.4 g (0.10 mol) of 7-hydroxycoumarin and 200 mL of formic acid were mixed, and light irradiation was performed at 80 degreeC for 60 hours using the high pressure mercury lamp of 500 W. The reaction mixture was mixed with 1,000 mL of distilled water for reprecipitation, and a solid was obtained by suction filtration. The obtained solid was recrystallized from dimethylacetamide to obtain 9.9 g (0.031 mol) of the compound (B-1) represented by the above formula (B-1).

example 2

[0206] Mix 9.6 g (0.030 mol) of compound (B-1), 3.168 g (0.066 mol) of a 50% by weight oil suspension of sodium hydride, 54 mL of toluene, and 36 mL of N,N-dimethylformamide, and mix at 80° C. , The reaction was carried out under stirring for 1 hour. Next, after cooling the reaction mixture to 20° C., 10.5 g (0.063 mol) of 1,4-dinitrobenzene was added dropwise thereto in 18 mL of N,N-dimethylformamide over 1 hour. After completion of the dropwise addition, reaction was carried out at 110° C. under stirring for 64 hours. After cooling the reaction mixture to 5° C., 270 mL of distilled water was added thereto, and extraction was performed with 180 mL of dichloromethane. The dichloromethane layer was washed three times with 150 mL of distilled water, dried over magnesium sulfate, and the solvent was removed under reduced pressure. The obtained solid was recrystallized from ethanol to obtain 10.8 g (0.019 mol) of the compound (B-2) represented by the above formula (B-2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com