Method of manufacturing a needle assembly for use with a biopsy device

a biopsy device and manufacturing method technology, applied in the field of biopsy devices, can solve the problems of requiring significant time and expense to make and attach the needle, no single procedure is ideal for all cases, and the process known in the art for manufacturing these needles is often expensive and labor-intensive. achieve the effect of maintaining the necessary biomechanical properties and reducing the cost of manufacturing the biopsy needle devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

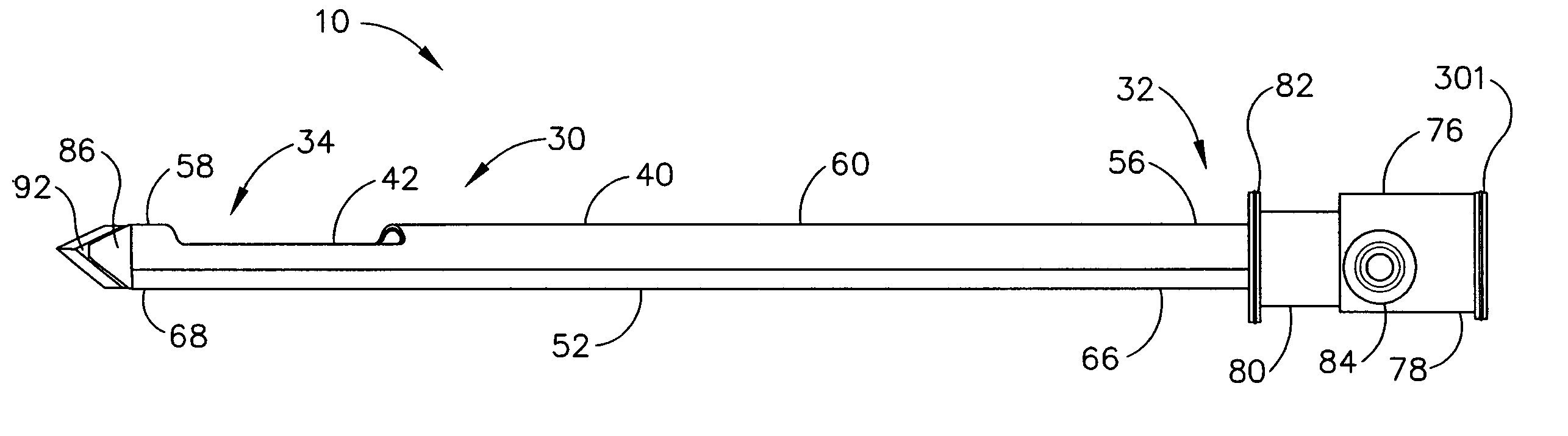

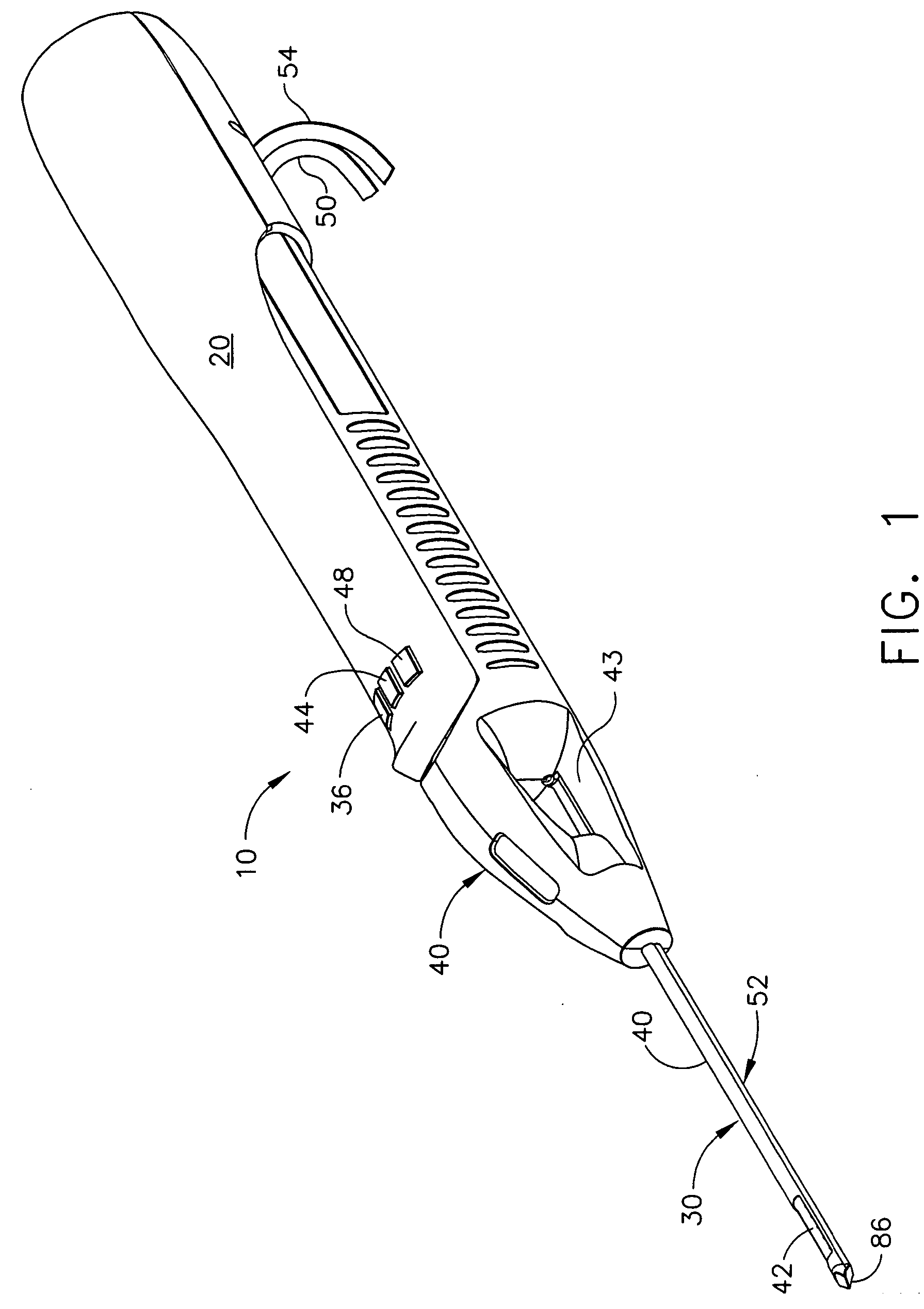

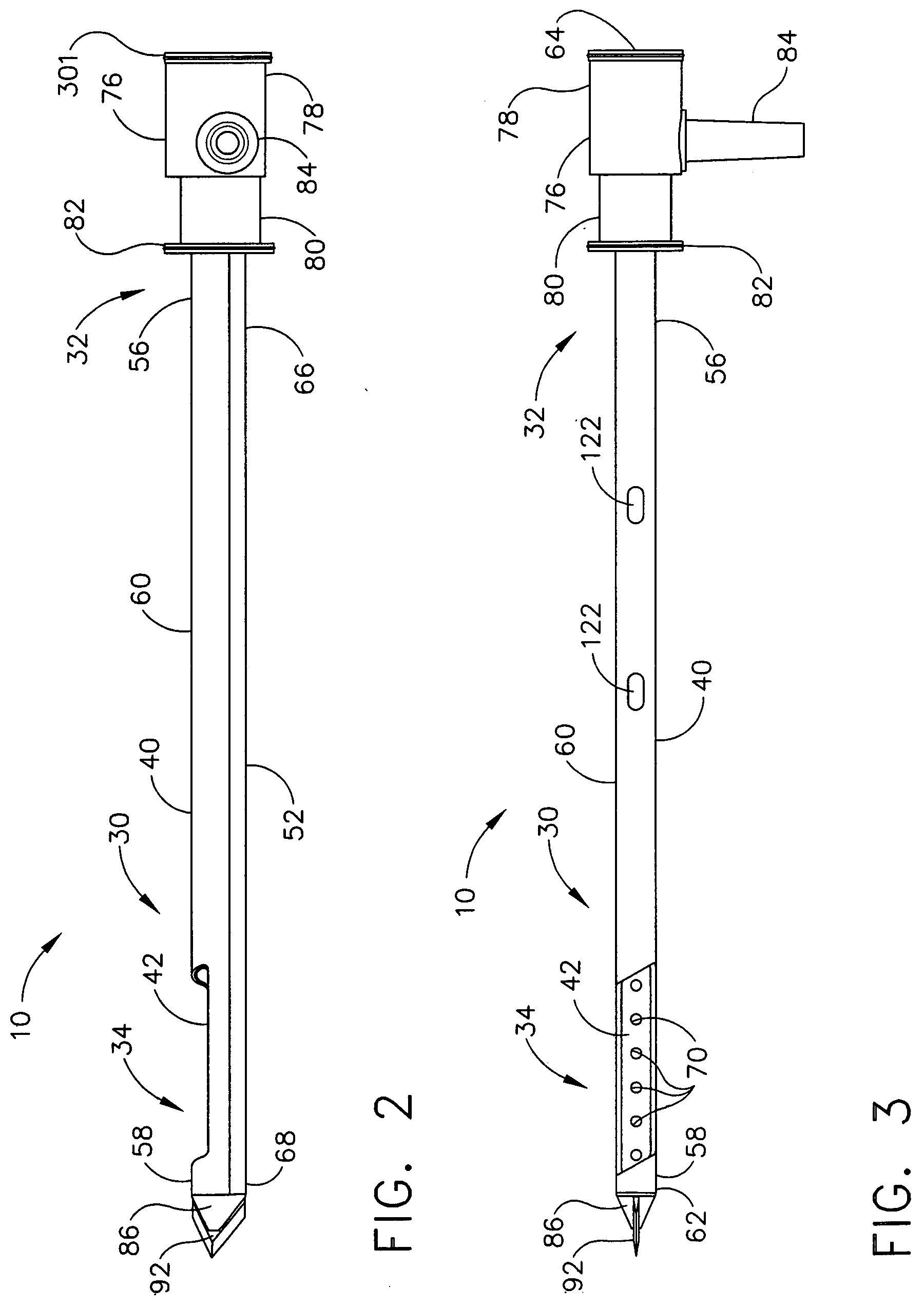

[0027]FIG. 1 shows a hand-held vacuum-assisted biopsy device 10 comprising a handle 20 detachably connected to a needle assembly 30 having a proximal portion 32 and a distal portion 34 manufactured according to a version of the process of the current invention. Together, they constitute a lightweight, ergonomically-shaped, hand-manipulated biopsy device 10. In one aspect, needle assembly 30 may be part of a disposable probe that may mount on handle 20. In one aspect, hand-held biopsy device 10 may be used in conjunction with an ultrasound to guide needle assembly 30. Since handle 20 may be manipulated by the operator's hand, the operator may steer needle assembly 30 with great freedom towards the tissue mass of interest. The surgeon has tactile feedback while doing so and may therefore ascertain to a significant degree the density and hardness of the tissue being encountered. In addition, handle 20 may be held approximately parallel to the chest wall of a patient for obtaining tissu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquid crystal | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| vacuum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com