Semiconductor producing device and semiconductor producing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

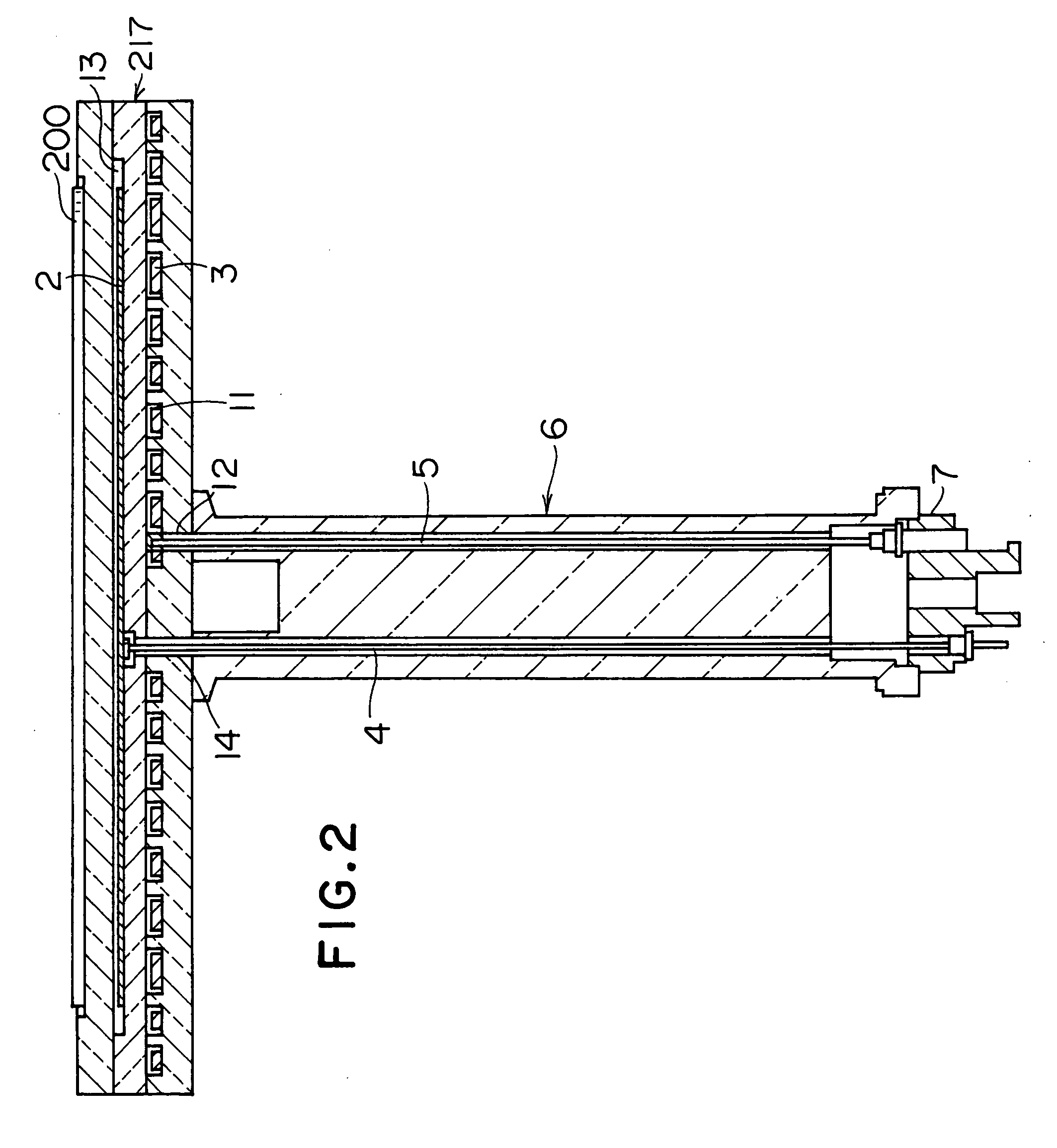

[0049]FIG. 3 is a frontal cross sectional view of a section of the susceptor of the MMT device of the present invention. FIG. 4 is a plan view taken along line IV-IV of FIG. 3.

[0050] The susceptor 217 of this embodiment is formed from quartz or aluminum nitride. Preferably, quartz is utilized since a large temperature differential occurs within the susceptor 217 in the high temperature region for example of 500° C. or more, and the strength must be maintained. Incidentally, neither quartz or aluminum nitride do not cause metallic contamination effects on the wafer 200 which is the substrate for processing.

[0051] The susceptor 217 of the present embodiment is comprised of a first susceptor member 1a as a lid, and a second susceptor member 1b as the main piece. A groove 8 is formed in a lattice shape in the upper surface of the second susceptor member 1b. A high frequency electrode 2a in a mesh shape and serving as the second electrode is installed on the groove 8 and the first susce...

third embodiment

[0059]FIG. 5 is a partial cross sectional front view showing the susceptor of the MMT device of the present invention.

[0060] The overall structure of the MMT device of this embodiment and the schematic structure of the susceptor are the same as the previously described MMT device and susceptor.

[0061] The susceptor 217 of this embodiment is comprised of an upper stage susceptor member 1c and intermediate stage susceptor member 1d and lower stage susceptor member le and a mounting susceptor member if. The material is overall quartz. The high frequency electrode 2a serving as the second electrode is installed inside the upper stage susceptor member 1c.

[0062] The mounting susceptor member 1f is fabricated separately from the upper stage susceptor member 1c and clamped air-tight by adhesive material or heat weld. The mounting susceptor member 1f may however be formed as one piece with the upper stage susceptor member 1c.

[0063] An upper side cavity 10a is formed on the upper surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com