Method for mounting a drive shaft of a compressor

a technology of compressors and drive shafts, applied in the direction of engine lubrication, electrical apparatus, dynamo-electric machines, etc., can solve the problems of increasing energy consumption, increasing the energy consumption of the motor, and requiring relatively heavy wear on the bearings, so as to simplify the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

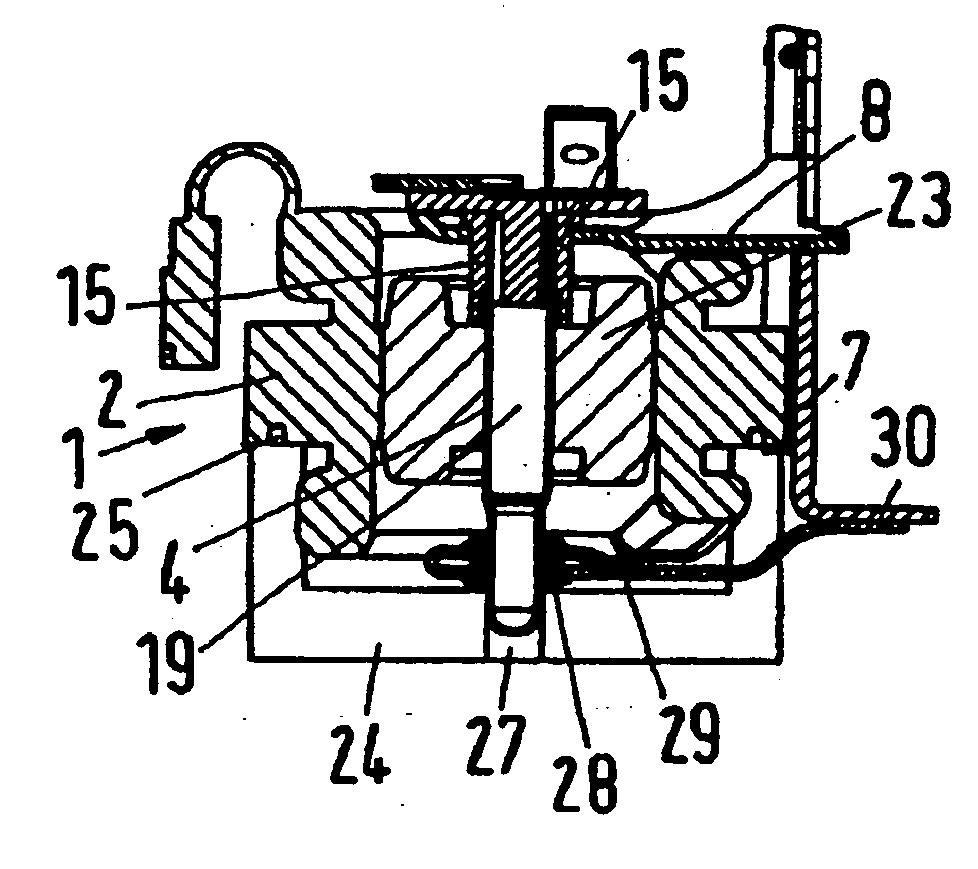

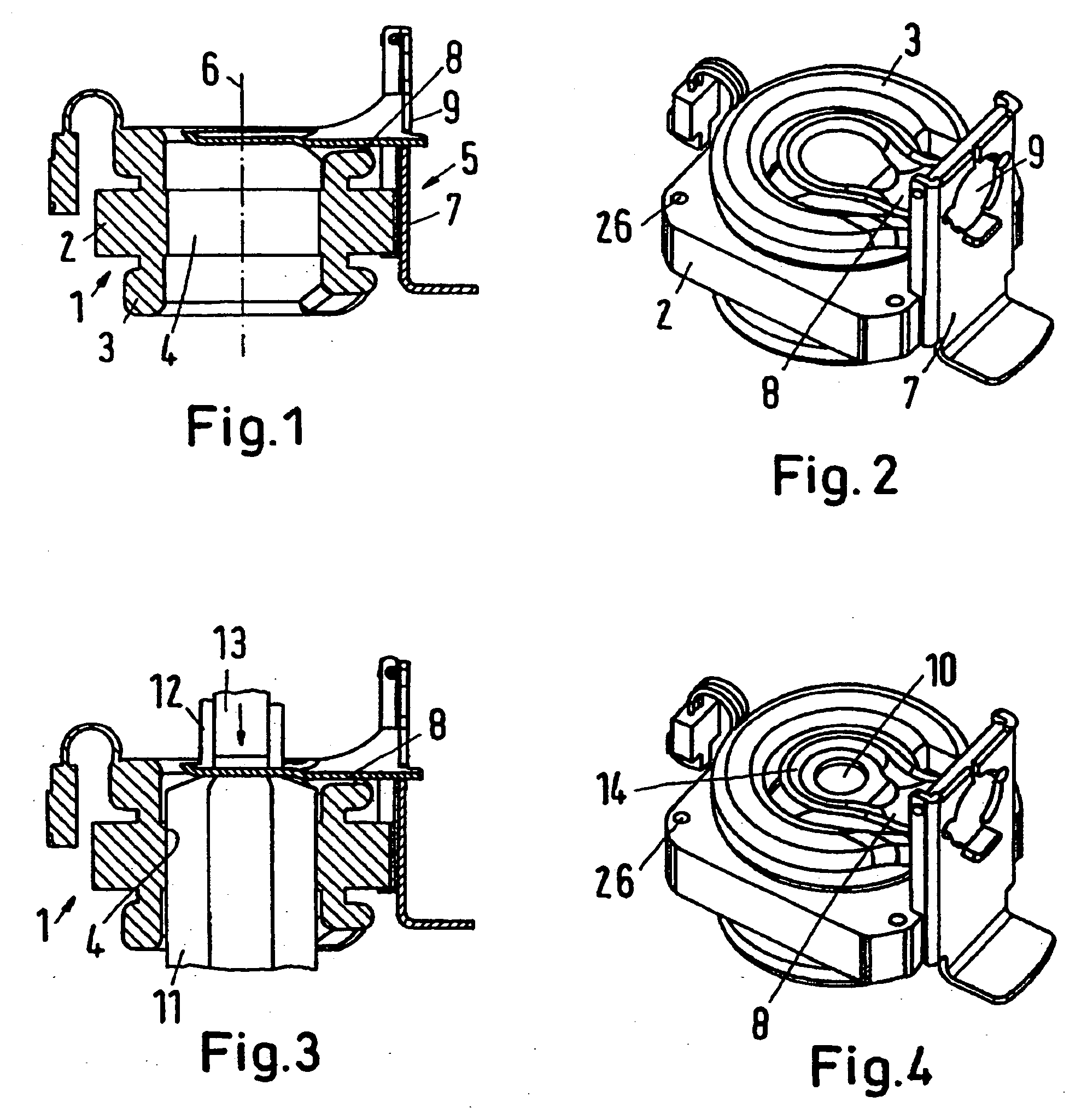

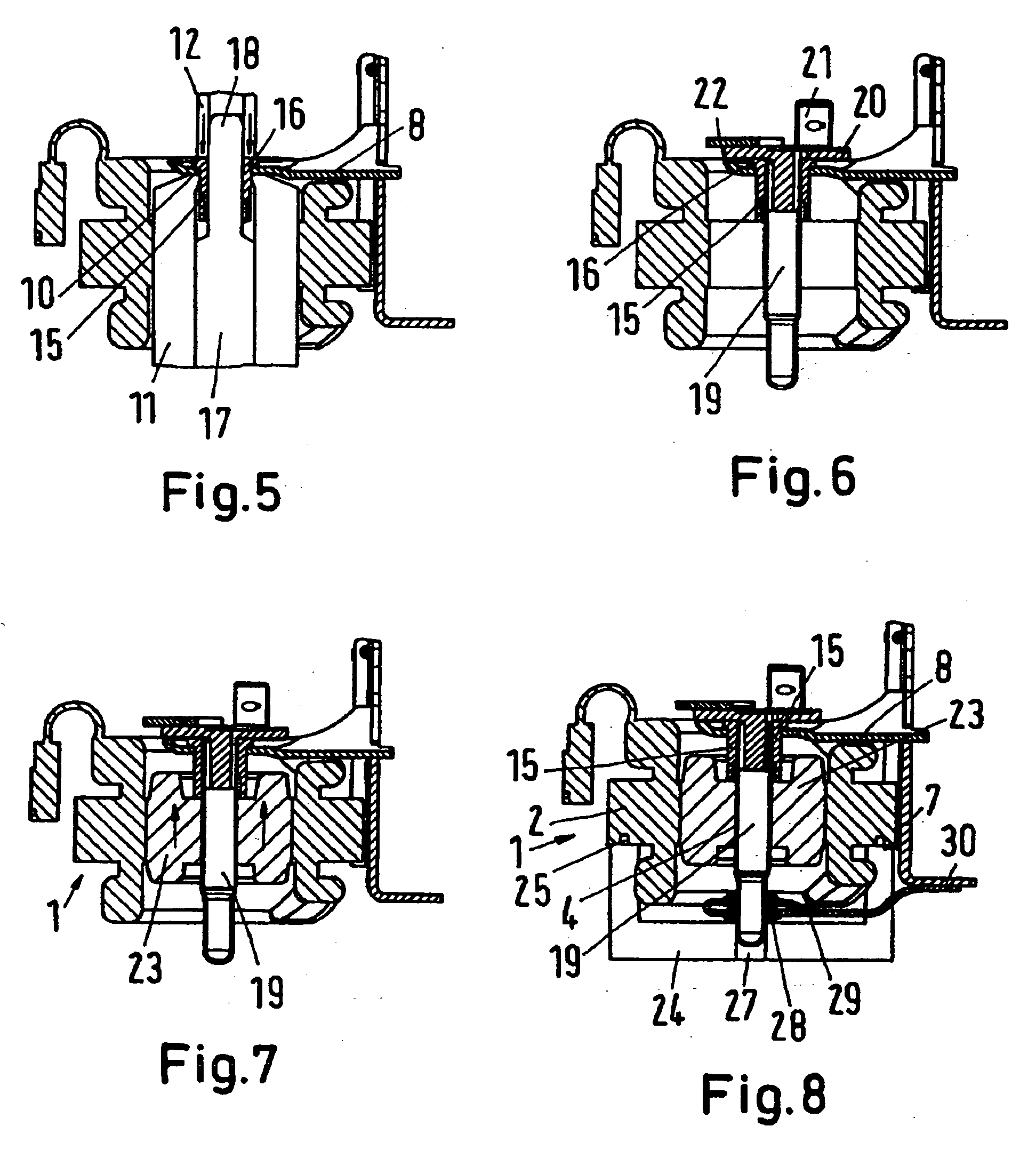

[0030]FIG. 1 shows a stator 1 of a motor, which is used for driving a compressor, particularly a refrigerant compressor. The stator 1 has a sheet pack 2 and a coil, of which coil ends 3 are shown. The sheet pack 2 surrounds a rotor opening 4. The rotor opening 4 is made in that already during the punching; the sheets forming the sheet pack 2 are provided with a central opening, so that the rotor opening 4 occurs, when the sheets of the sheet pack 2 are stacked.

[0031] A compressor block 5 is mounted and fixedly connected, for example by welding, on the outside of the sheet pack 2. The compressor block 5 can, for example, be a sheet metal part. The compressor block 5 has a basic unit 7 extending substantially parallel to the axis 6 of the stator 1, on which unit 7 a first bearing support 8 is fixed, for example by welding. After fixing on the basic unit 7, the first bearing support 8 forms a one-side suspended beam, which extends across the rotor opening 4. Both the basic unit 7 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radial displacement | aaaaa | aaaaa |

| energy losses | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com