Down hole physical upgrading of heavy crude oils by selective energy absorption

a technology of selective energy absorption and heavy crude oil, which is applied in the direction of fluid removal, borehole/well accessories, insulation, etc., can solve the problems of rapid cracking of heavy hydrocarbons to any degree desired by electromagnetic energy absorption, and achieve precise temperature control and energy efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A variety of different types of down hole electromagnetic structures may be employed to apply electromagnetic energy to heavy crude oil in situ. The proper structure for any particular application depends on a variety of factors, including depth, heat uniformity, and minimizing the degree of coking and production of unsaturated hydrocarbons.

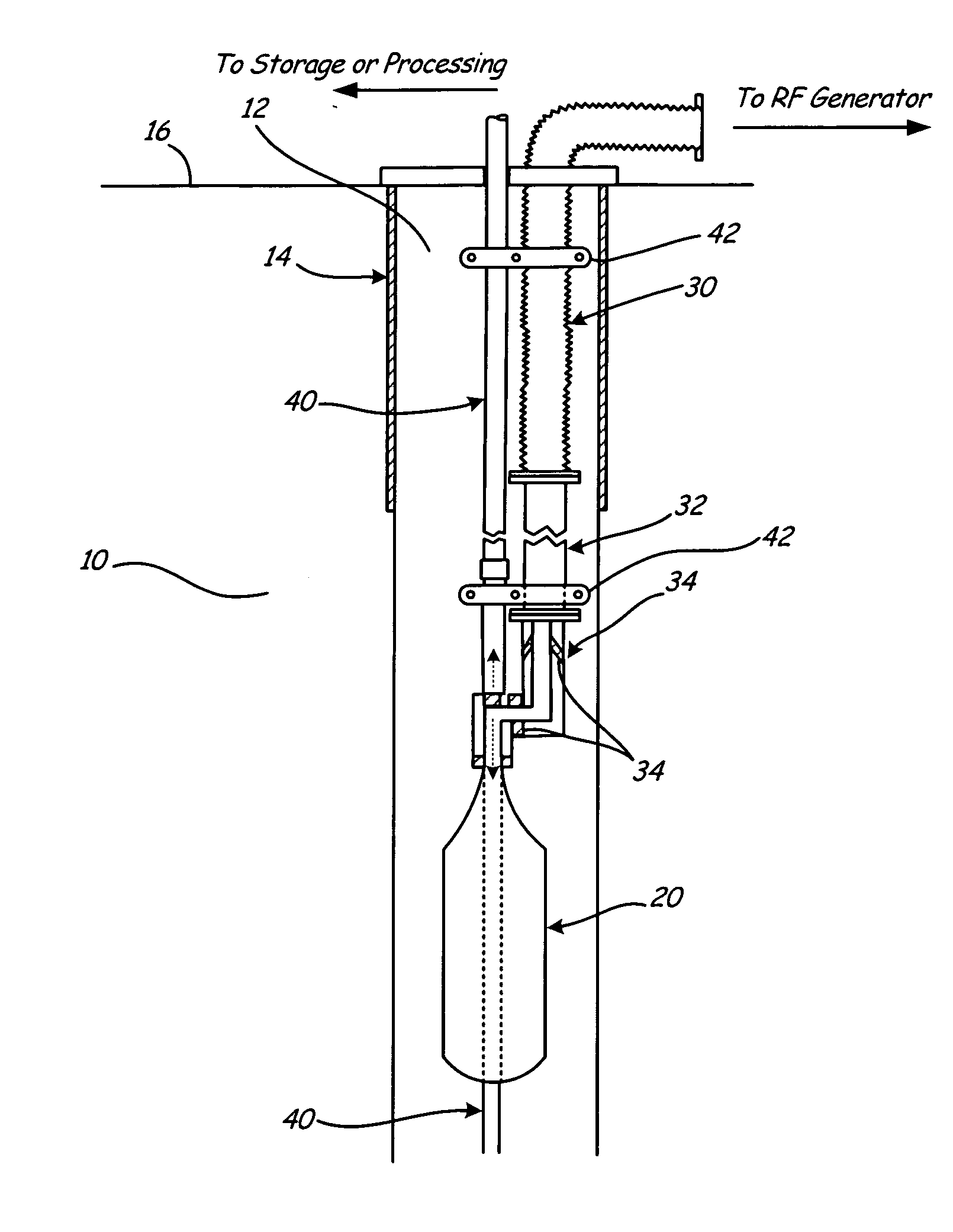

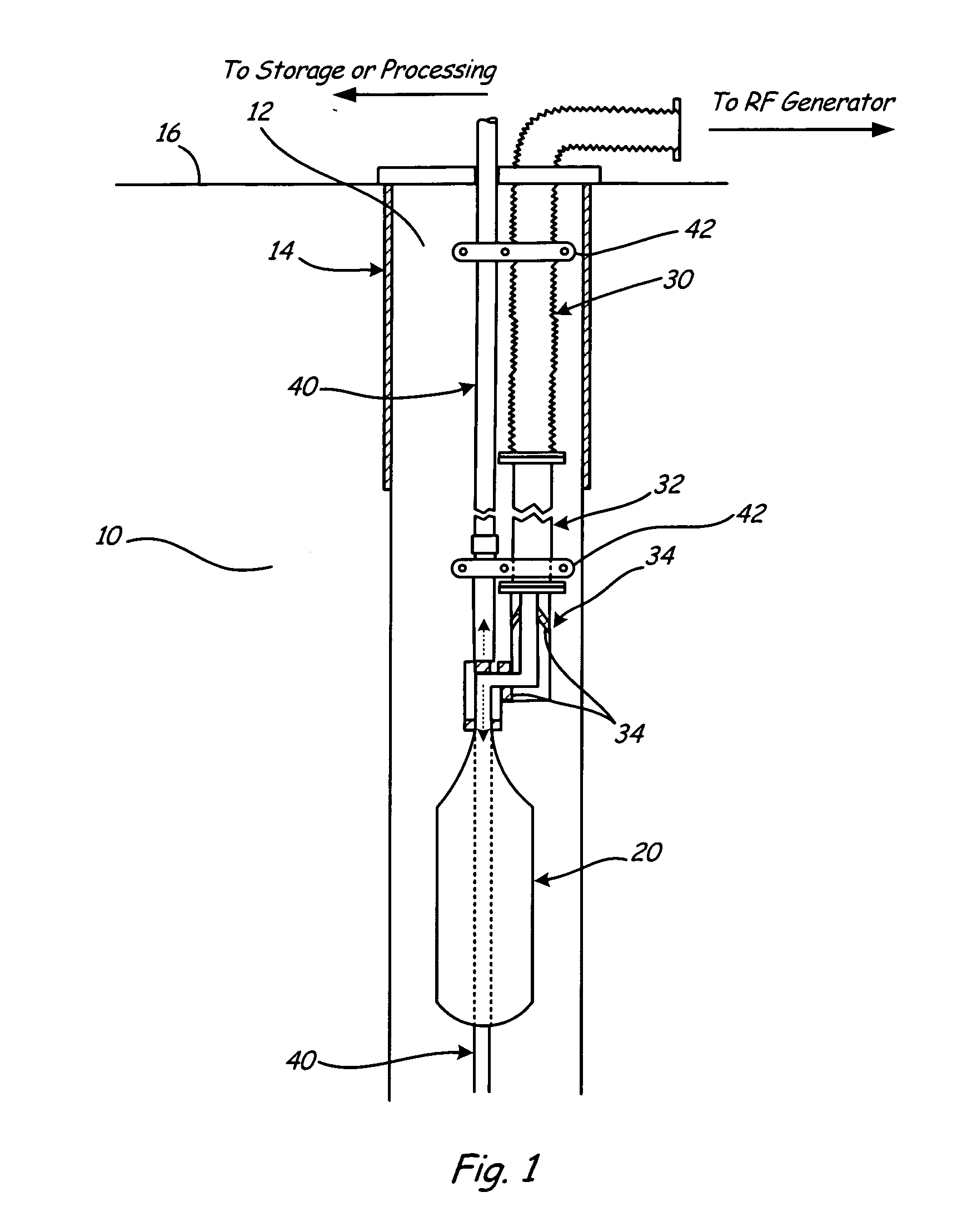

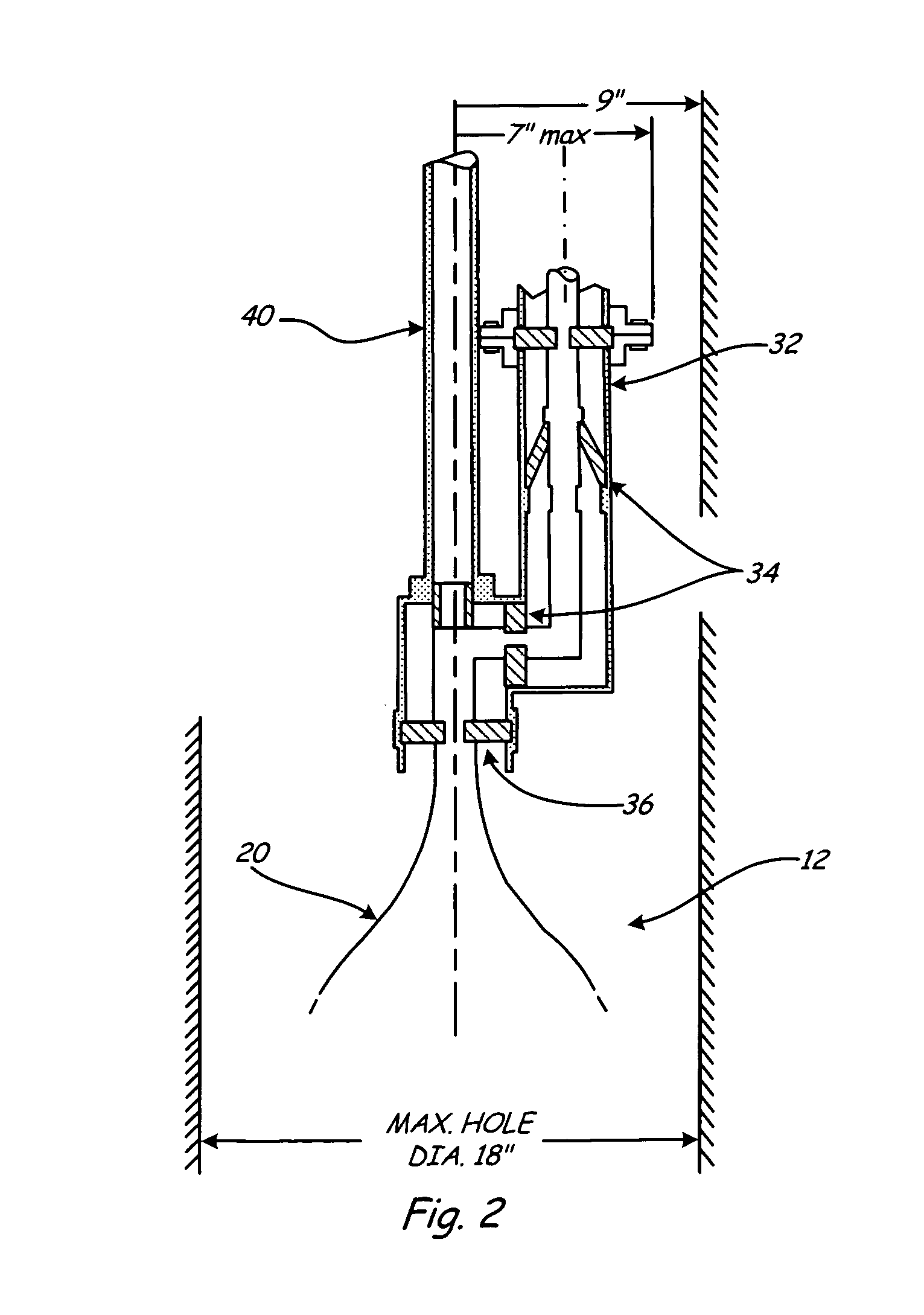

[0020]FIG. 1 is a perspective view of a single borehole radiation type applicator. Applicator system 10 is positioned within borehole 12. Borehole 12 is supported by casing 14. Applicator system 10 is then used to apply electromagnetic energy to heavy crude oil in the vicinity of borehole 12.

[0021] Applicator structure 20 is a transmission line retort. For a point of reference, a typical applicator 20 may be approximately 70 feet long. In a typical configuration, the applicator 20 may be positioned from between 100 to 600 feet underground in borehole 12. Radiofrequency (“RF”) energy is supplied to applicator 20 by an RF generator (not sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com