Self-molding annuloplasty ring

a technology of annuloplasty and self-molding, which is applied in the field of self-molding annuloplasty rings, can solve the problems of affecting the heart's function, affecting the efficiency of implantation surgery, and reducing the effect of implantation surgery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following detailed description and the accompanying drawings are intended to describe and show certain presently preferred embodiments of the present invention, and are not intended to limit the scope of the invention in any way.

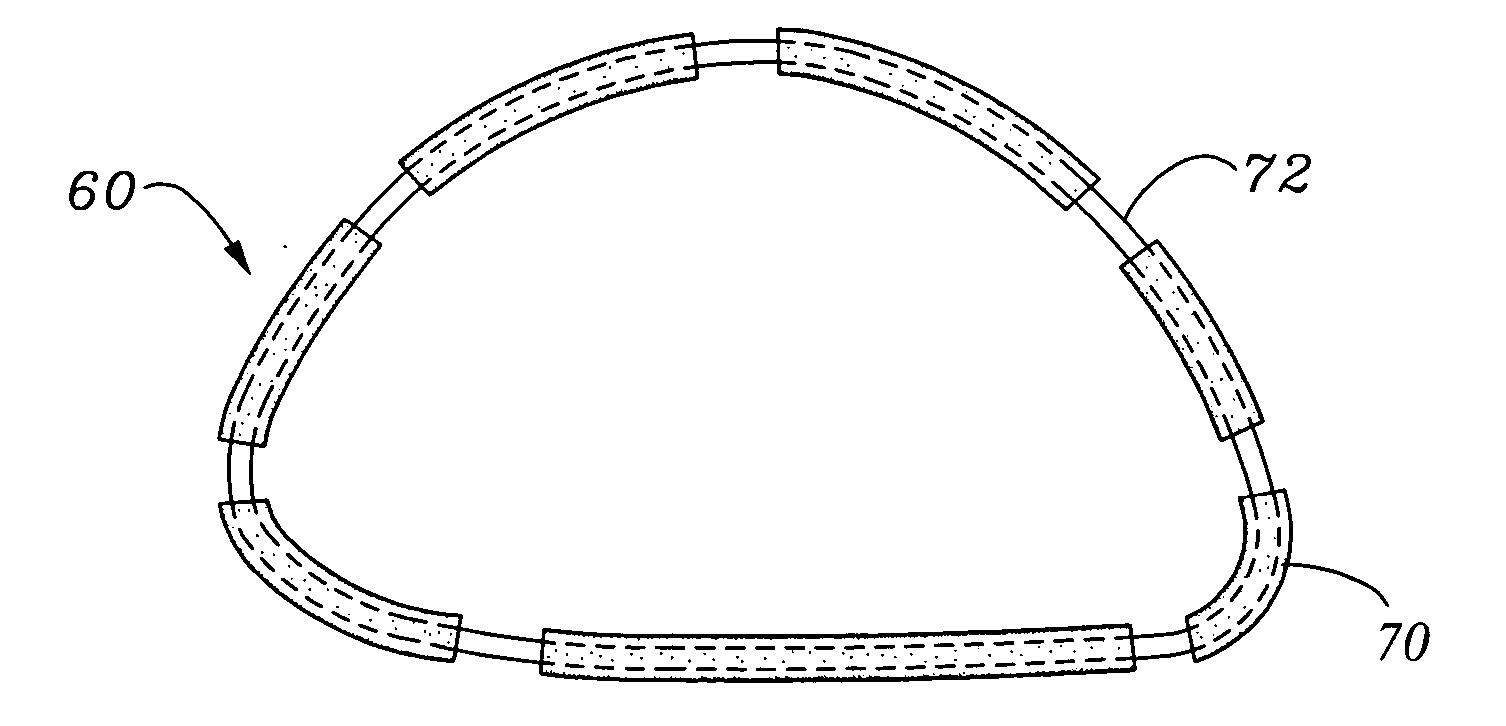

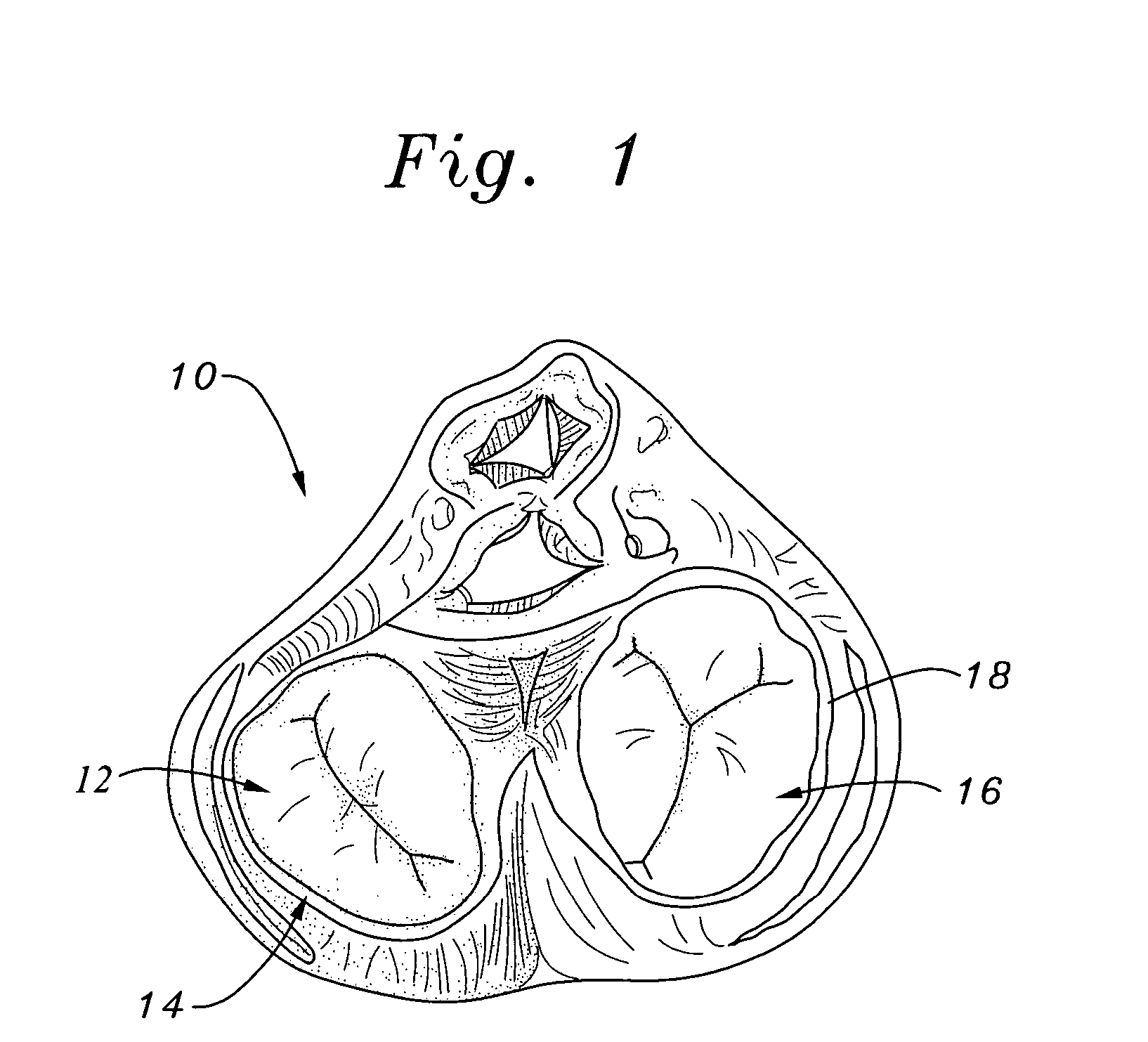

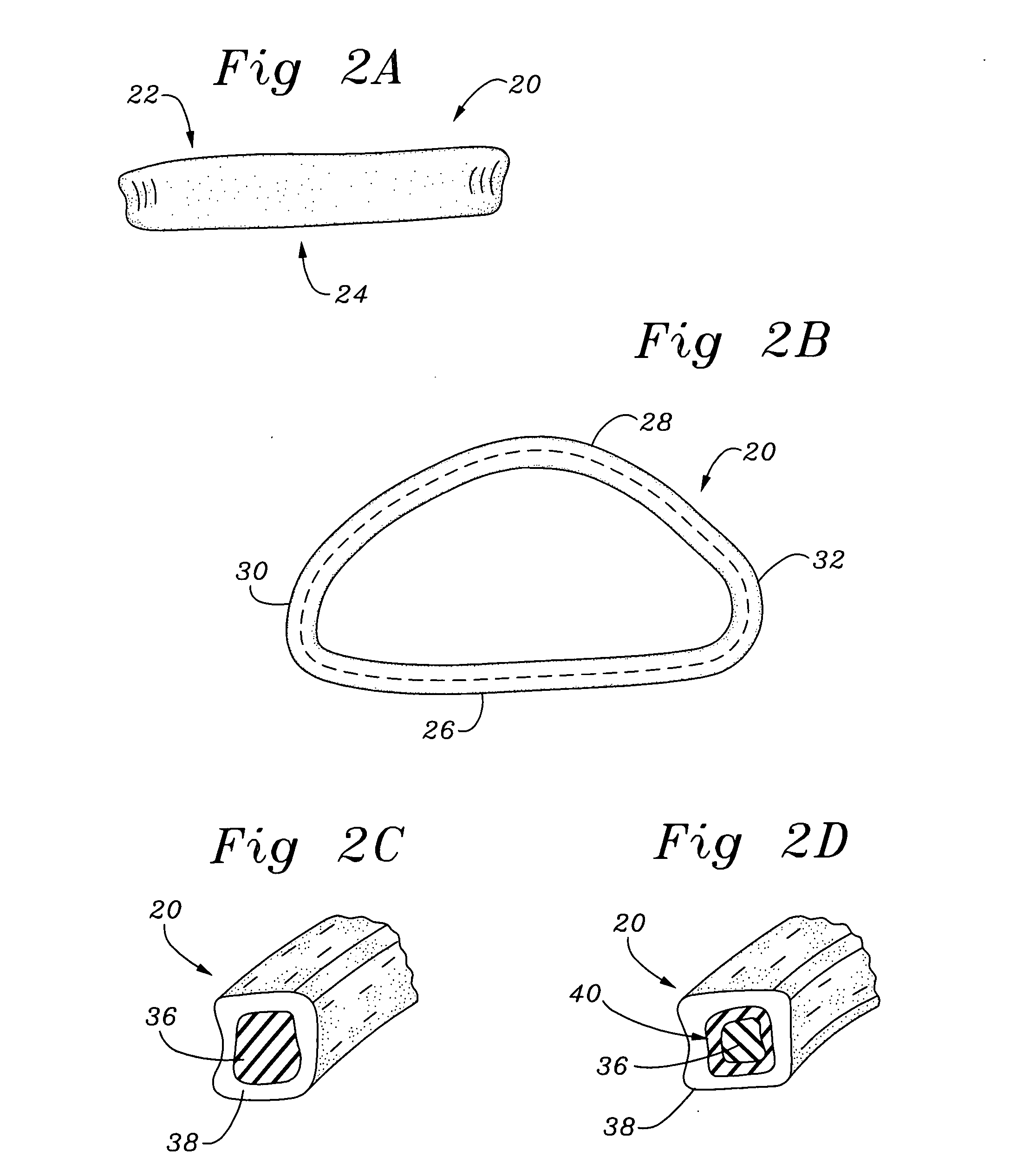

[0028] The self-molding annuloplasty ring of the present invention is generally used in surgical procedures to repair an incompetent tissue annulus. More specifically, the present invention is used to render an otherwise incompetent heart valve competent by decreasing the diameter of the opening at the valvular junction. As those skilled in the art will appreciate, the present invention may be manufactured with varying degrees of pre-tension and contractive force, thereby permitting variations of the contraction of the anterior and / or posterior annuli. In addition, the present invention simplifies the implantation procedure by permitting pre-stretching of the annuloplasty ring to the diameter of the dilated annulus, and thereafter reducing the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com