Applying bond coat to engine components using cold spray

a technology of bond coat and engine components, applied in the direction of machines/engines, mechanical equipment, plasma techniques, etc., can solve the problems of limiting throughput, limiting the size of the parts that can be processed, and affecting the service life of the engine, so as to reduce cycle times and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

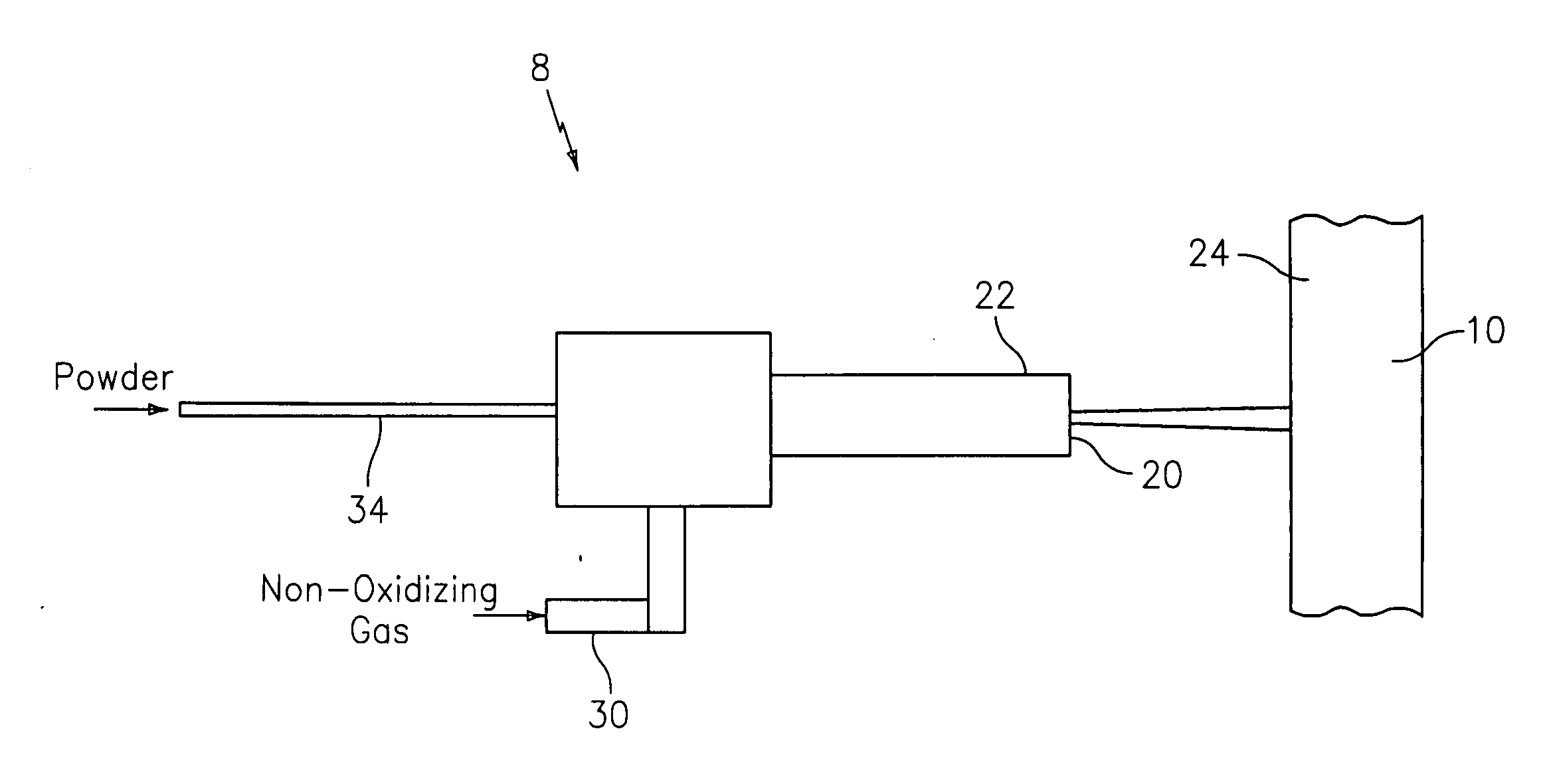

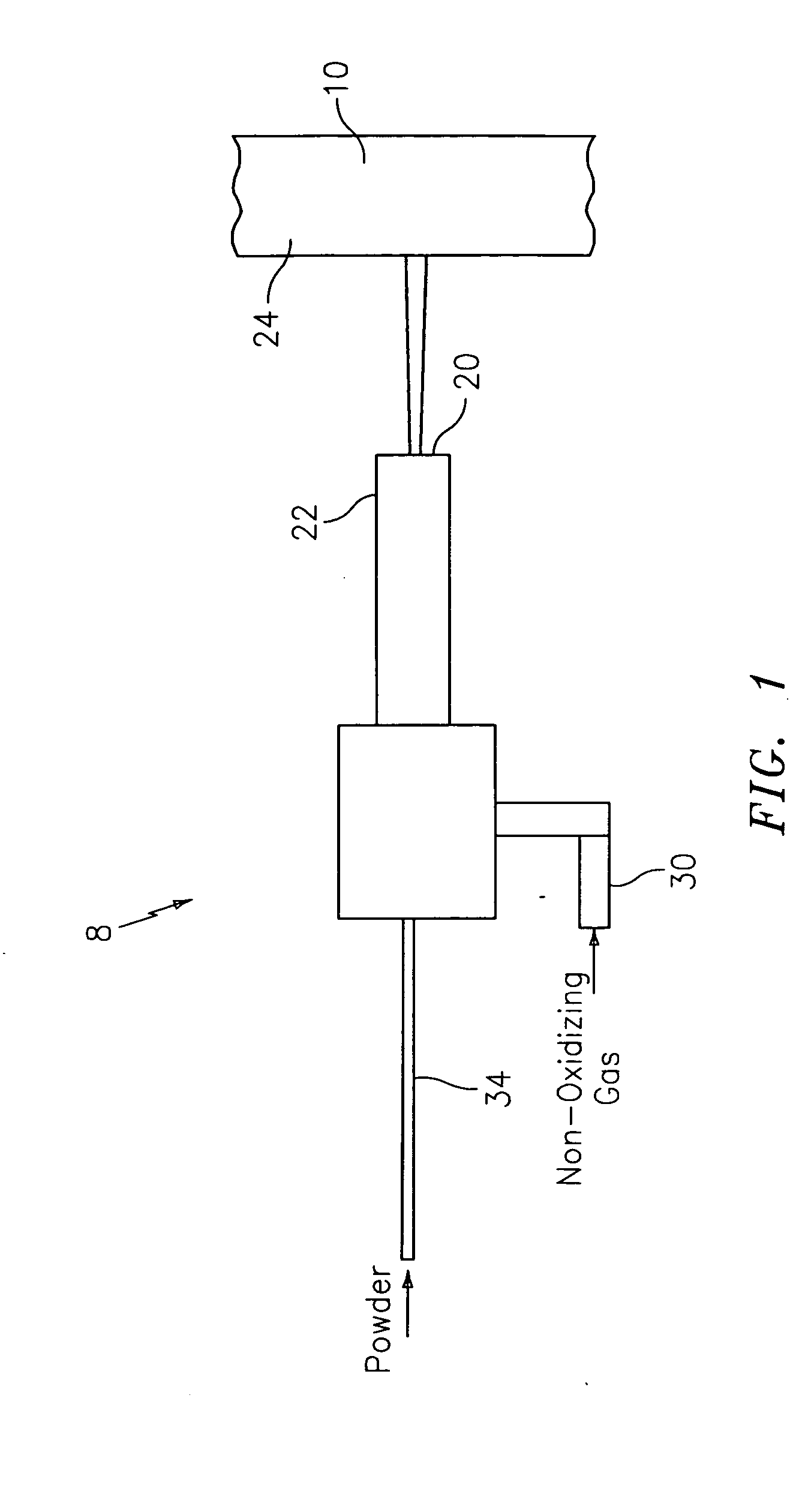

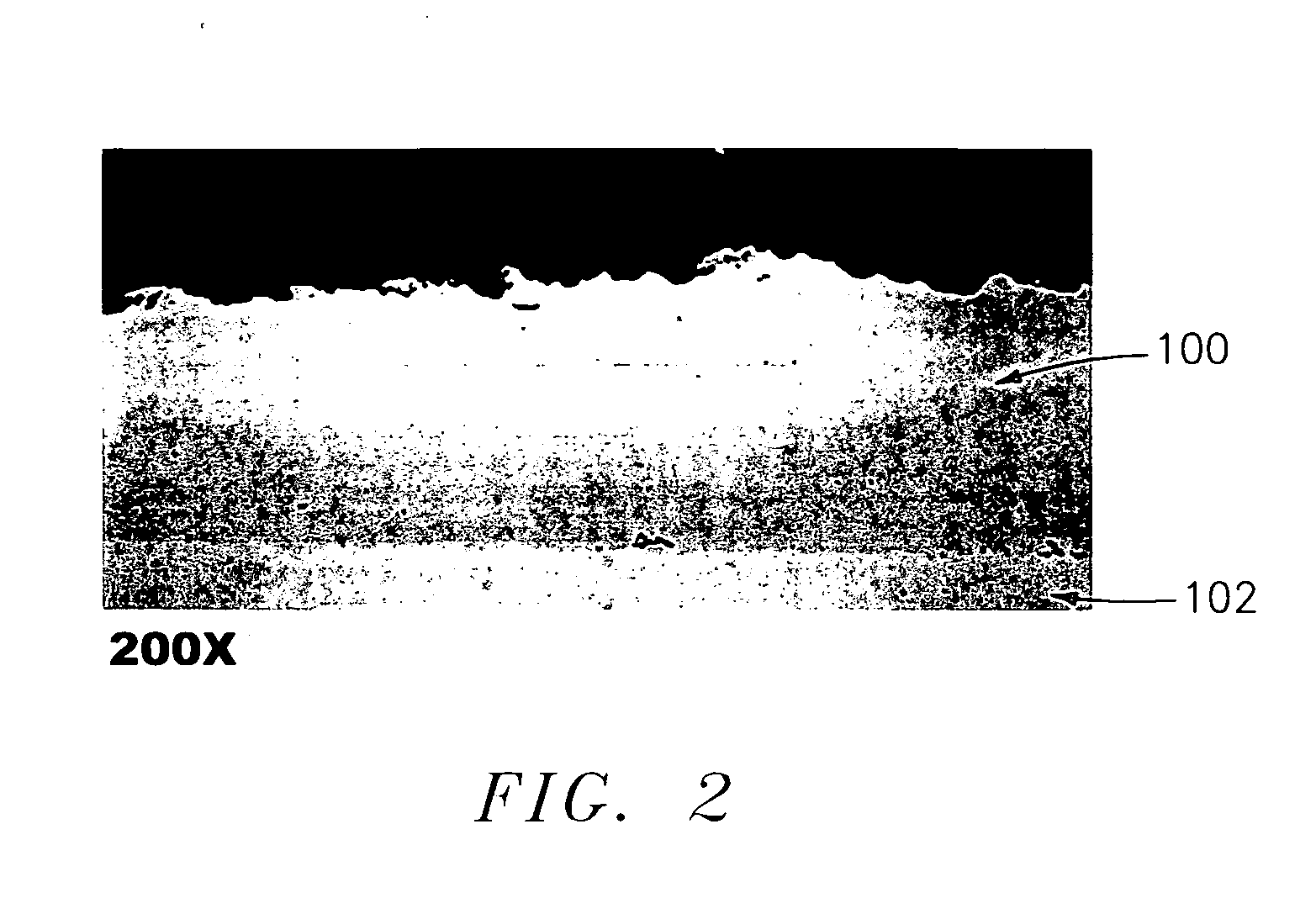

[0013] The present invention relates to a process for applying a coating to a component used in an engine. For example, the process of the present invention may be used to apply a MCrAlY coating to at least one surface of an airfoil portion on a turbine blade where M is Ni and / or Co or a variation. It may also be used to apply a bond coat to a combustion chamber liner used in rocket engines.

[0014] The cold spray process for depositing powdered materials onto portions of a component which needs to be restored is advantageous in that it provides sufficient energy to accelerate particles to high enough velocities such that, upon impact, the particles plastically deform and bond to the surface of the component being restored or onto a previously deposited layer. The cold spray process allows the build up of a relative dense coating or structural deposit. Cold spray does not metallurgically transform the particles from their solid state.

[0015] When preparing to coat an article or comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com