Vibration damper

a vibration damper and damper technology, applied in the direction of spring/damper design characteristics, machine supports, machine frames, etc., can solve the problems of generating noise on horizontal surfaces such as floors, requiring structures and/or equipment to be isolated, and common unwanted noise and vibration in many environments, etc., to achieve effective absorption of noise and vibration, easy installation and use, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

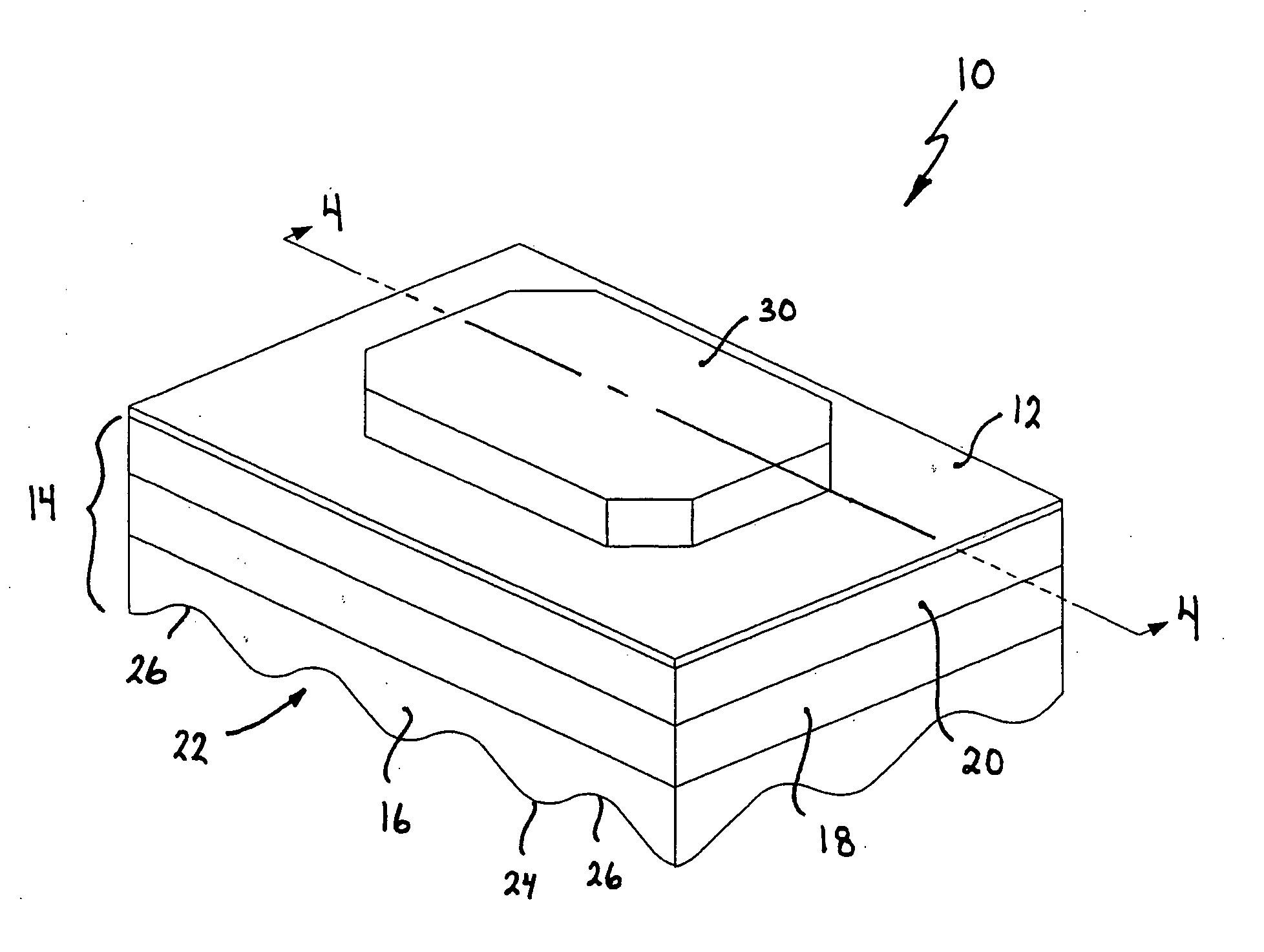

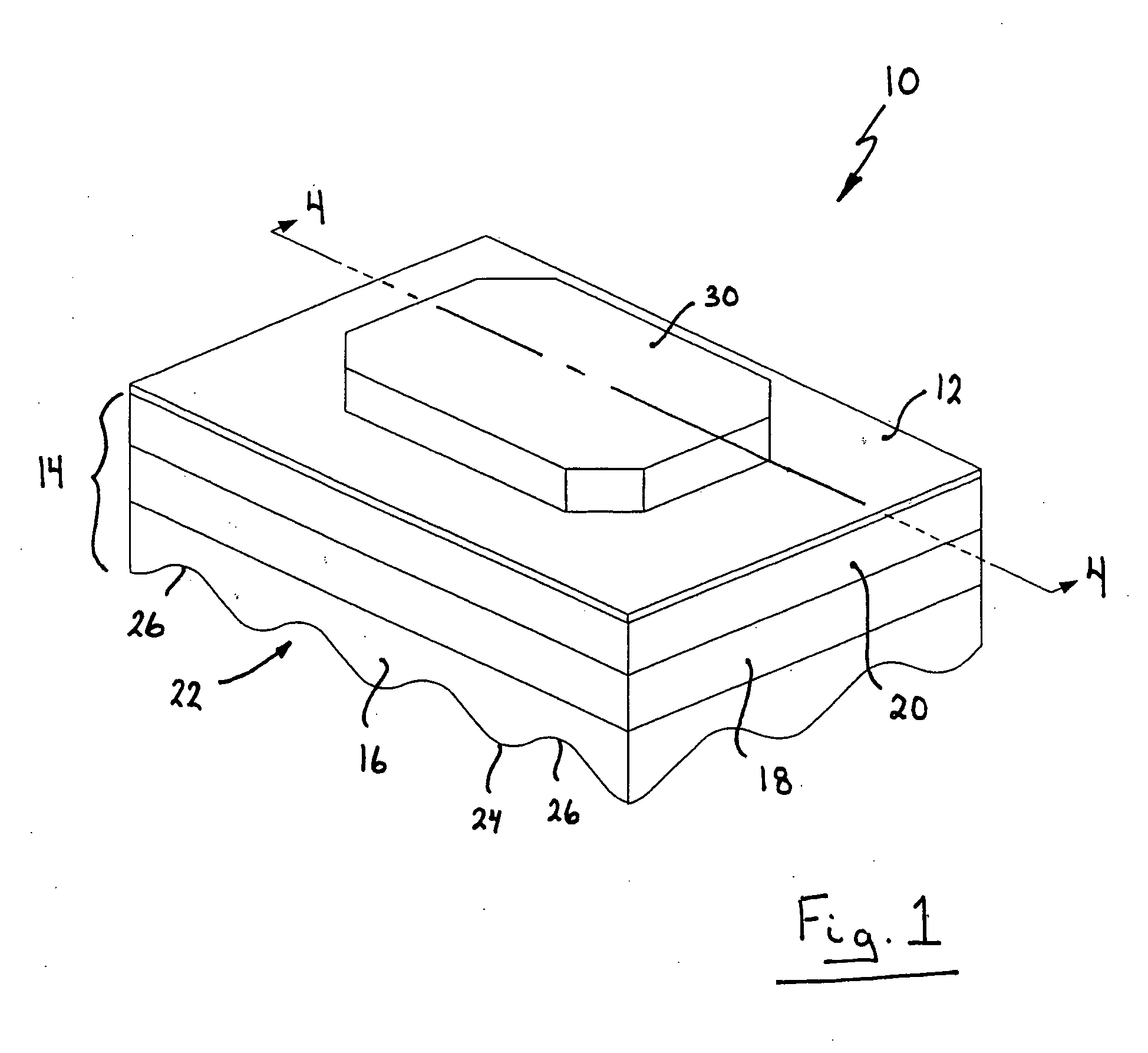

[0020] Turning now to FIGS. 1 to 4, a vibration damper is shown and is generally identified by reference numeral 10. Vibration damper 10 is designed to act between a support surface such as an underlying floor surface and residential or commercial equipment. Depending on the nature of the equipment to be supported, vibration damper 10 acts to inhibit impact and vibrational noise generated by the equipment from propogating to surrounding structures and / or to inhibit vibration in the surrounding environment from propogating to the equipment.

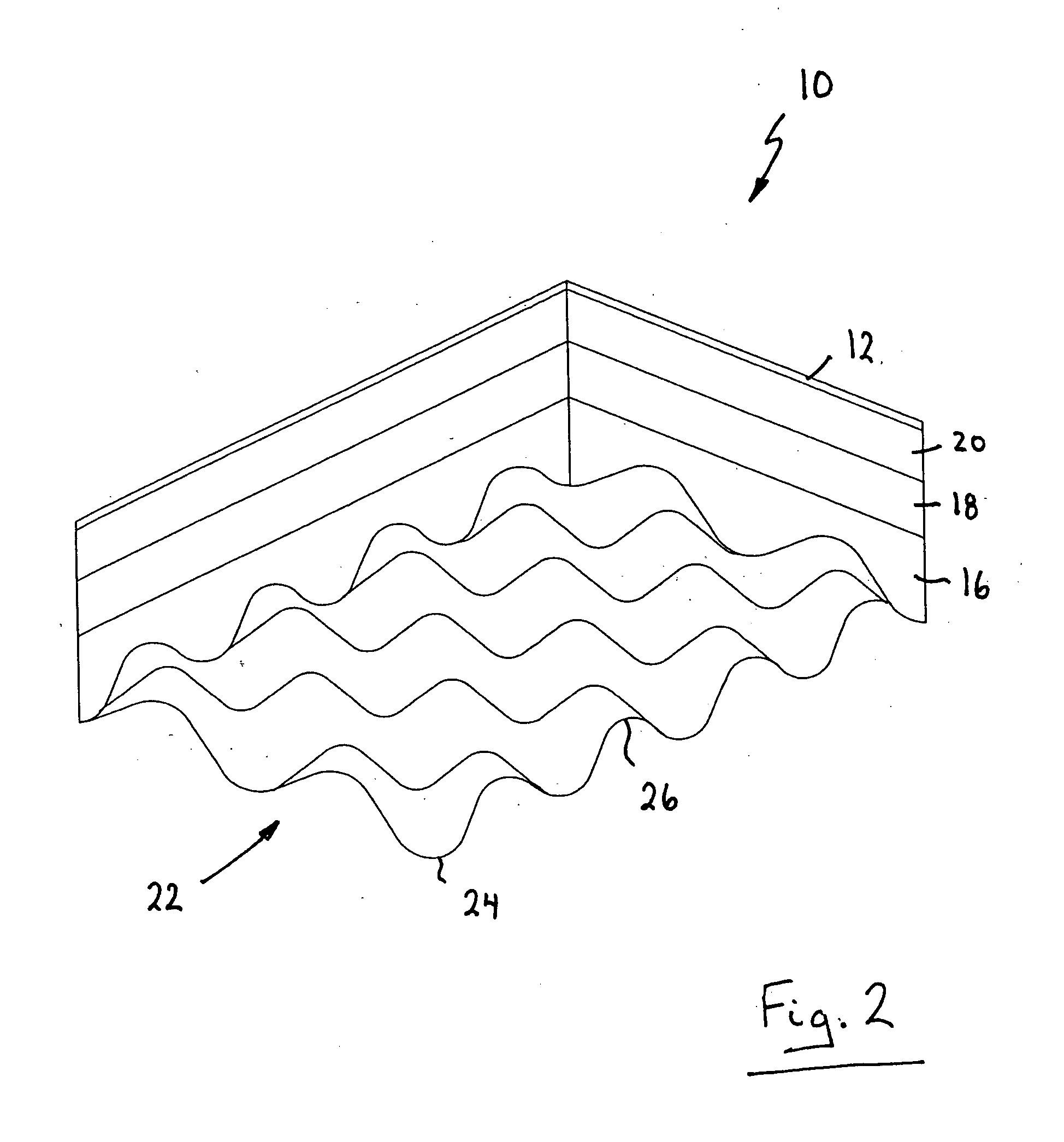

[0021] As can be seen, vibration damper 10 includes a load bearing plate 12 disposed on a vibration dampening structure 14. The vibration dampening structure 14 in this example includes a slip resistant lower layer 16 and a pair of intermediate foam layers 18 and 20 disposed between the lower layer 16 and the load bearing plate 12.

[0022] The bottom surface 22 of the lower layer 16 is contoured to define peaks 24 and valleys 26 that are sequential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com