Exhaust purification with on-board ammonia production

a technology of ammonia production and exhaust gas, which is applied in the direction of engines, mechanical equipment, machines/engines, etc., can solve the problems of high cost, hazardous ammonia storage, and inability to meet the requirements of on-board ammonia production, and achieve the effect of facilitating a reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

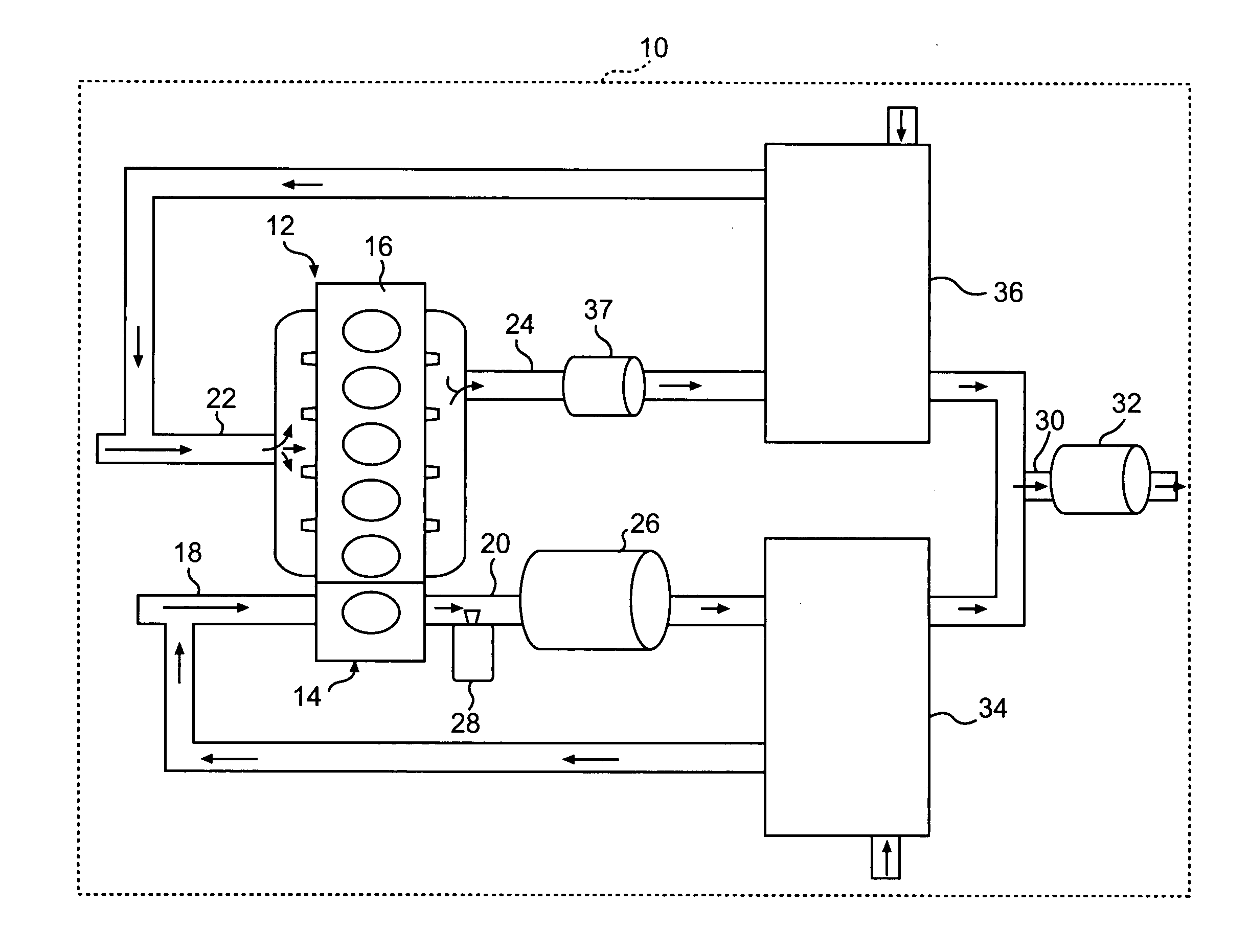

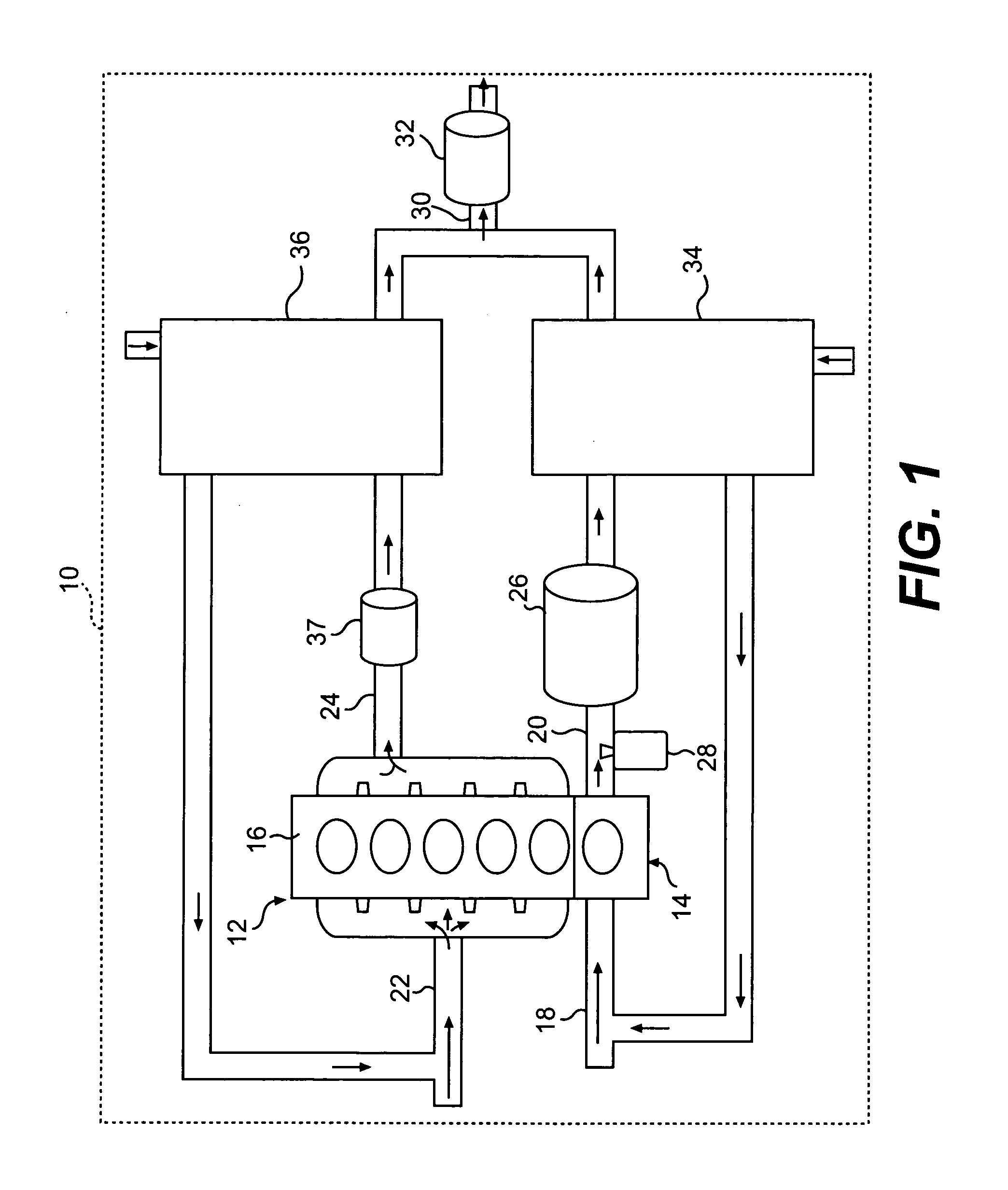

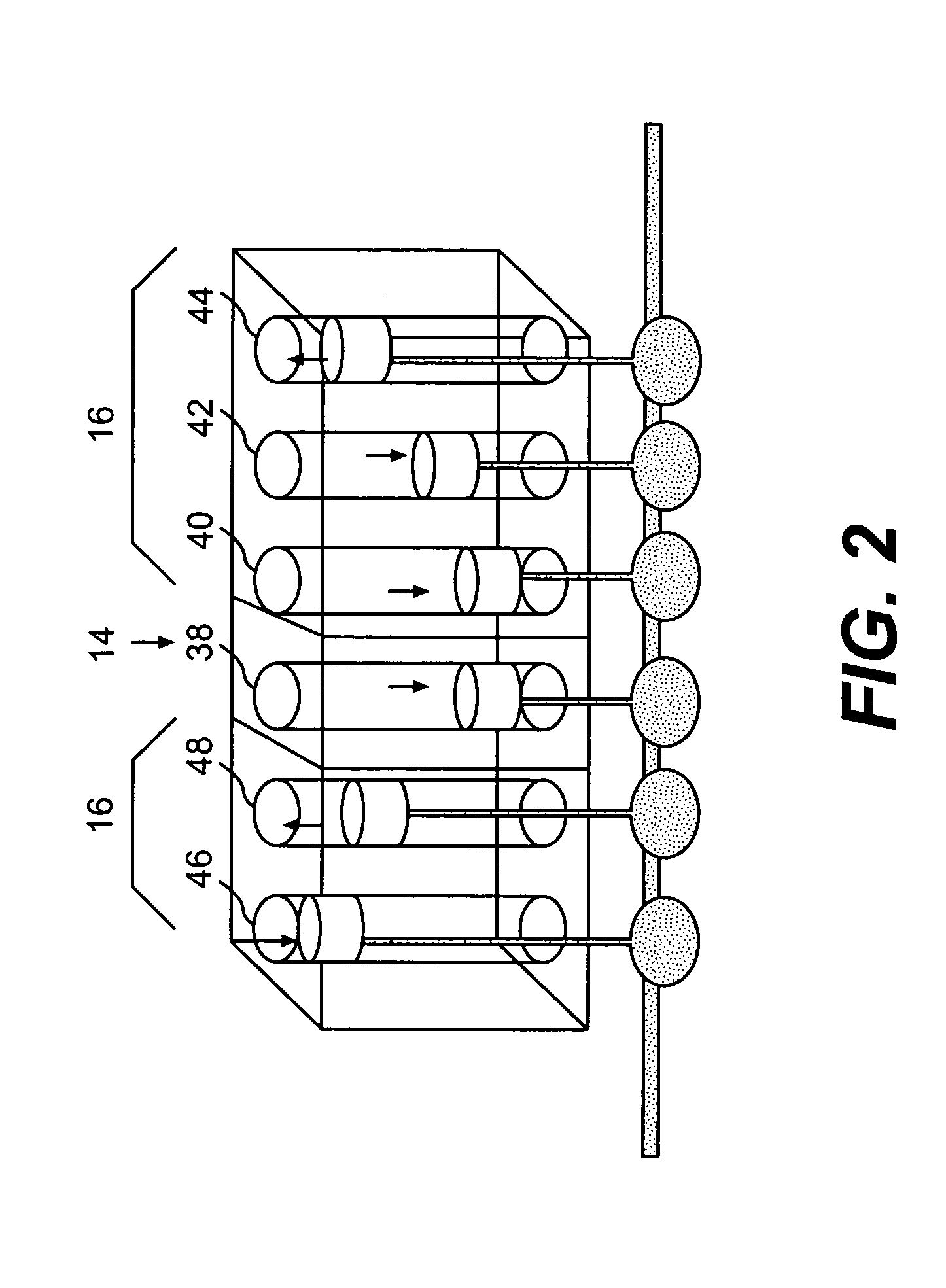

[0022]FIG. 1 provides a schematic representation of a machine 10 of the present disclosure including a power source 12. Power source 12 may include a first cylinder group 14 and a second cylinder group 16. First cylinder group 14 may be fluidly connected to a first air-intake passage 18 and a first exhaust passage 20. Second cylinder group 16 may be fluidly connected to a second air-intake passage 22 and a second exhaust passage 24. In one embodiment, first air-intake passage 18 is fluidly isolated from second air-intake passage 22.

[0023] The operation of engine cylinders may be dependant on the ratio of air to fuel-vapor that is injected into the cylinders during operation. The air to fuel-vapor ratio is often expressed as a lambda value, which is derived from the stoichiometric air to fuel-vapor ratio. The stoichiometric air to fuel-vapor ratio is the chemically correct ratio for combustion to take place. A stoichiometric air to fuel-vapor ratio may be considered to be equivalent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com