Droplet ejection apparatus

a technology of ejection apparatus and droplet, which is applied in the direction of photomechanical apparatus, instruments, printing, etc., can solve the problems of time and effort, difficult to accurately control parameters concerning difficult to accurately control parameters of droplet discharge and laser irradiation, etc., to achieve accurate and fast alignment of ejection droplets and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

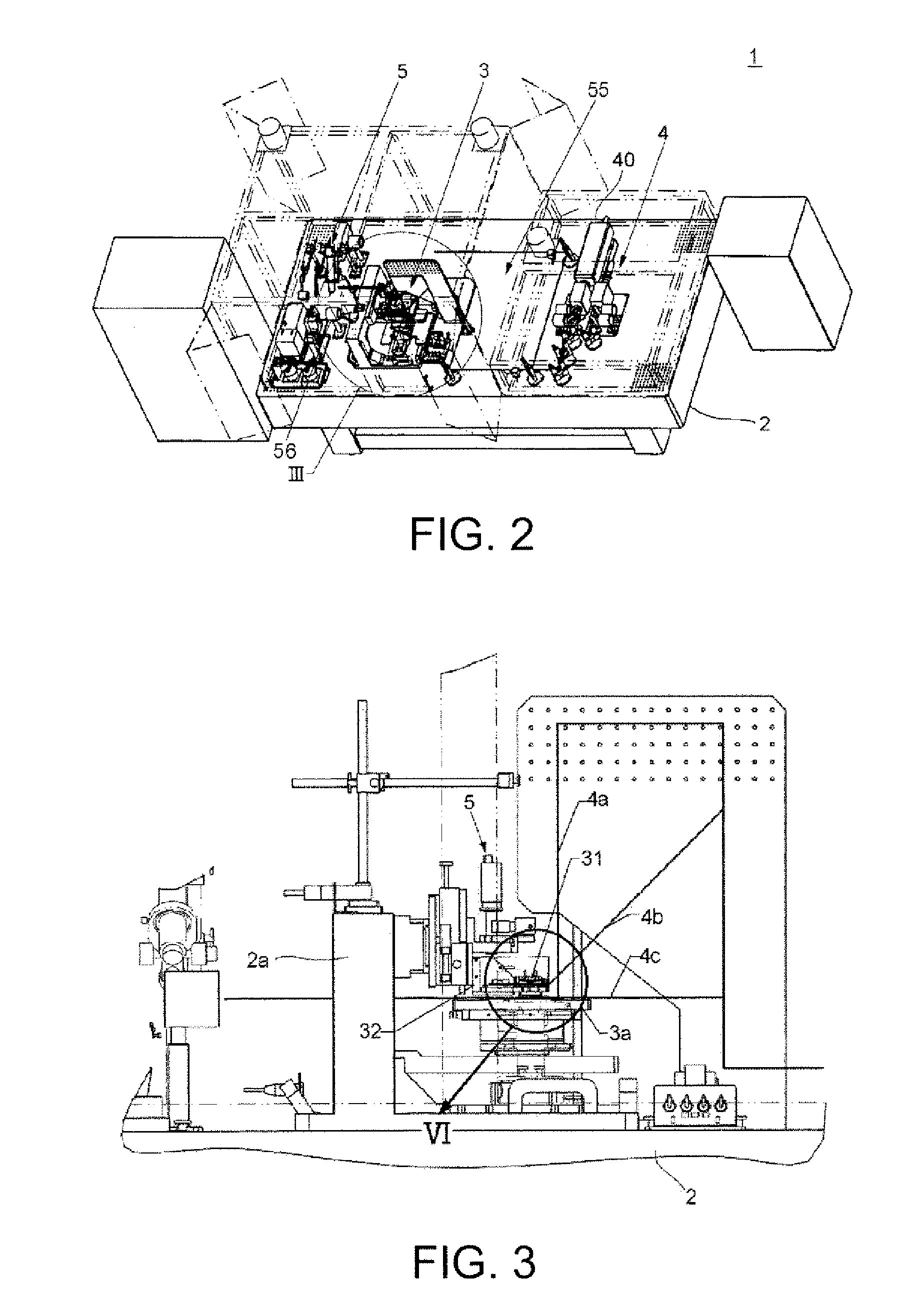

[0039] In an exemplary embodiment of the invention, the base is a vibration-proof base, and the plotting system and the optical system are established on the upper surface of the vibration-proof base as the reference surface. The plotting system and the optical system can be mounted on the base by such well-known anchoring means as bolts and nuts, chucks, welding, and bonding.

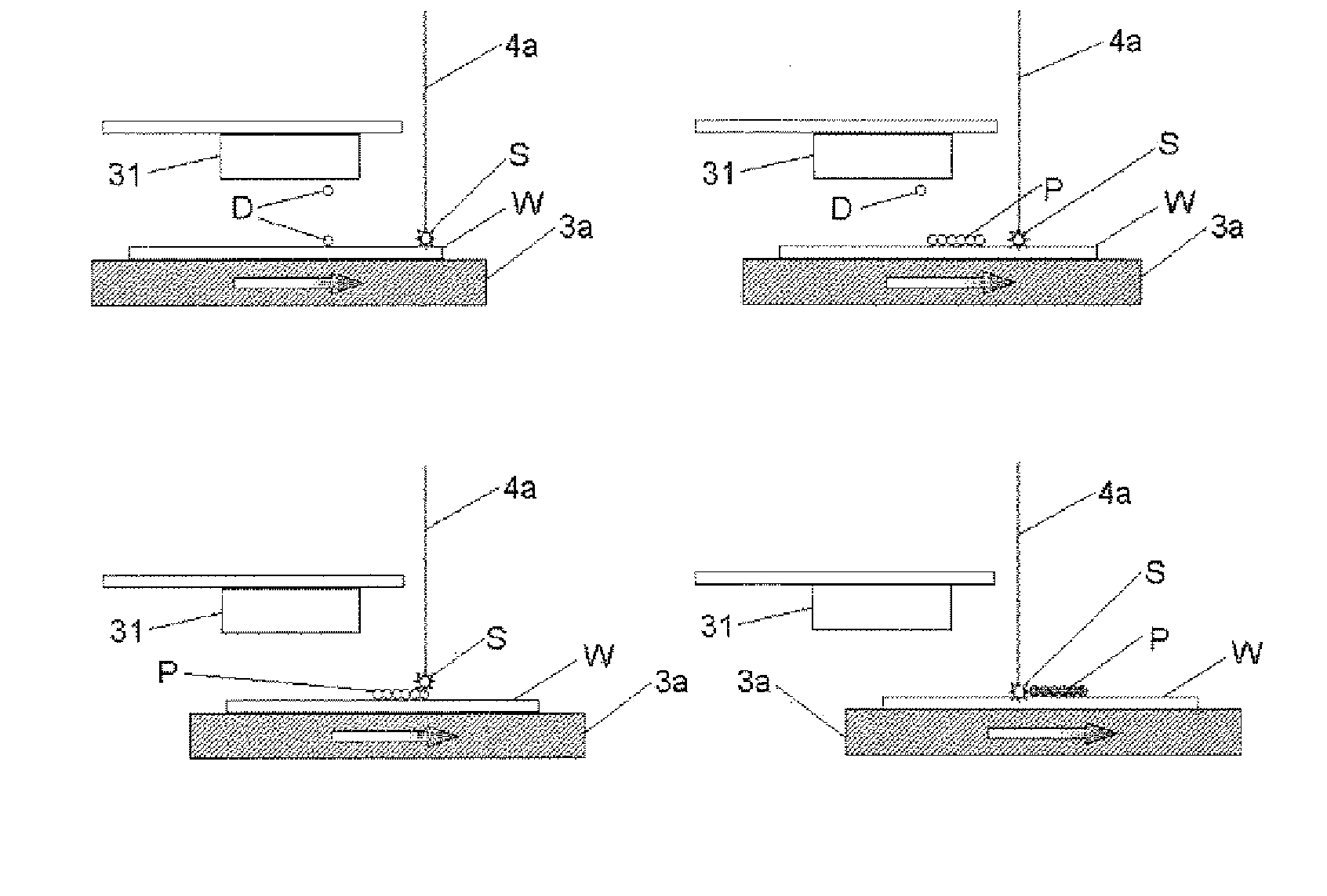

[0040] One working example of the invention will now be described referring to the drawings.

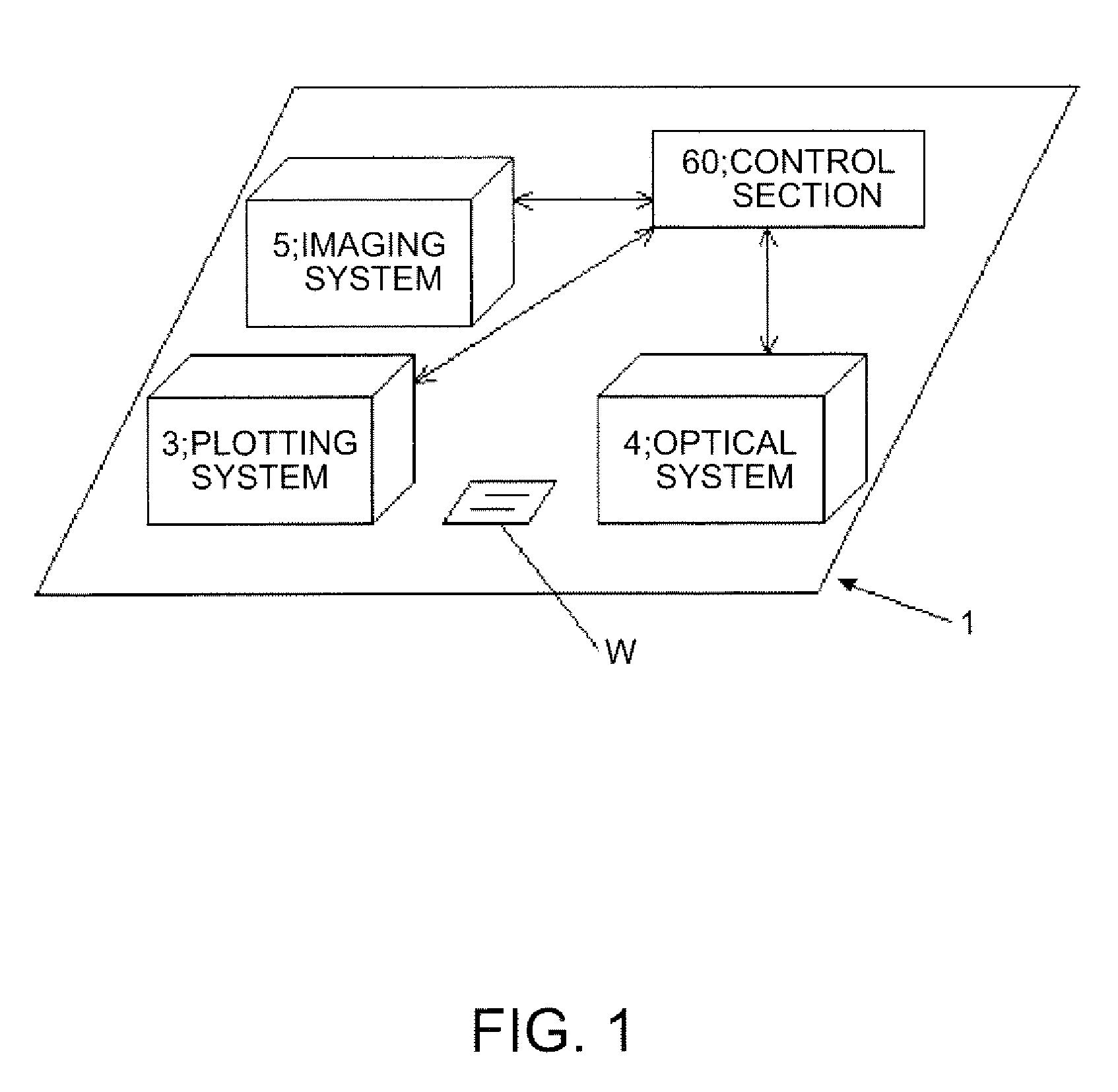

[0041]FIG. 1 is a schematic block diagram to explain the control structure of a droplet ejection apparatus according to one working example of the invention.

[0042]FIG. 1 illustrates the basic control structure of the droplet ejection apparatus according to one working example of the invention, which includes: on a base 1 whose upper surface being shared as the reference surface, a plotting system 3 that contains a droplet ejection head 31 and the like (see FIG. 2); an optical system 4 that contains first to third opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com