Centrifugal engine

a centrifugal engine and centrifugal technology, applied in the field of centrifugal engines, can solve problems such as limiting the maximum theoretical efficiency, and achieve the effects of less turbulence, less acoustic emissions, and reduced friction losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

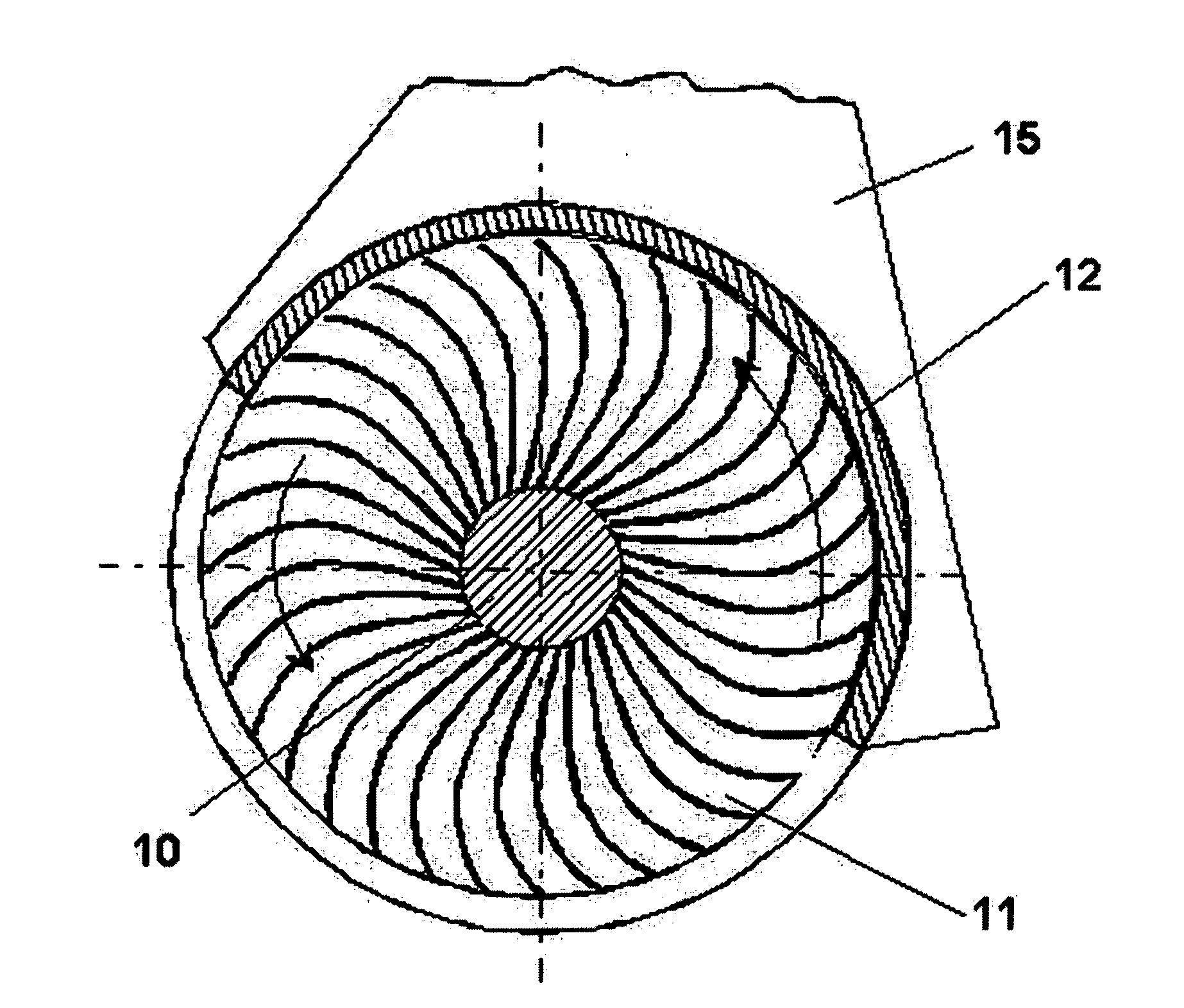

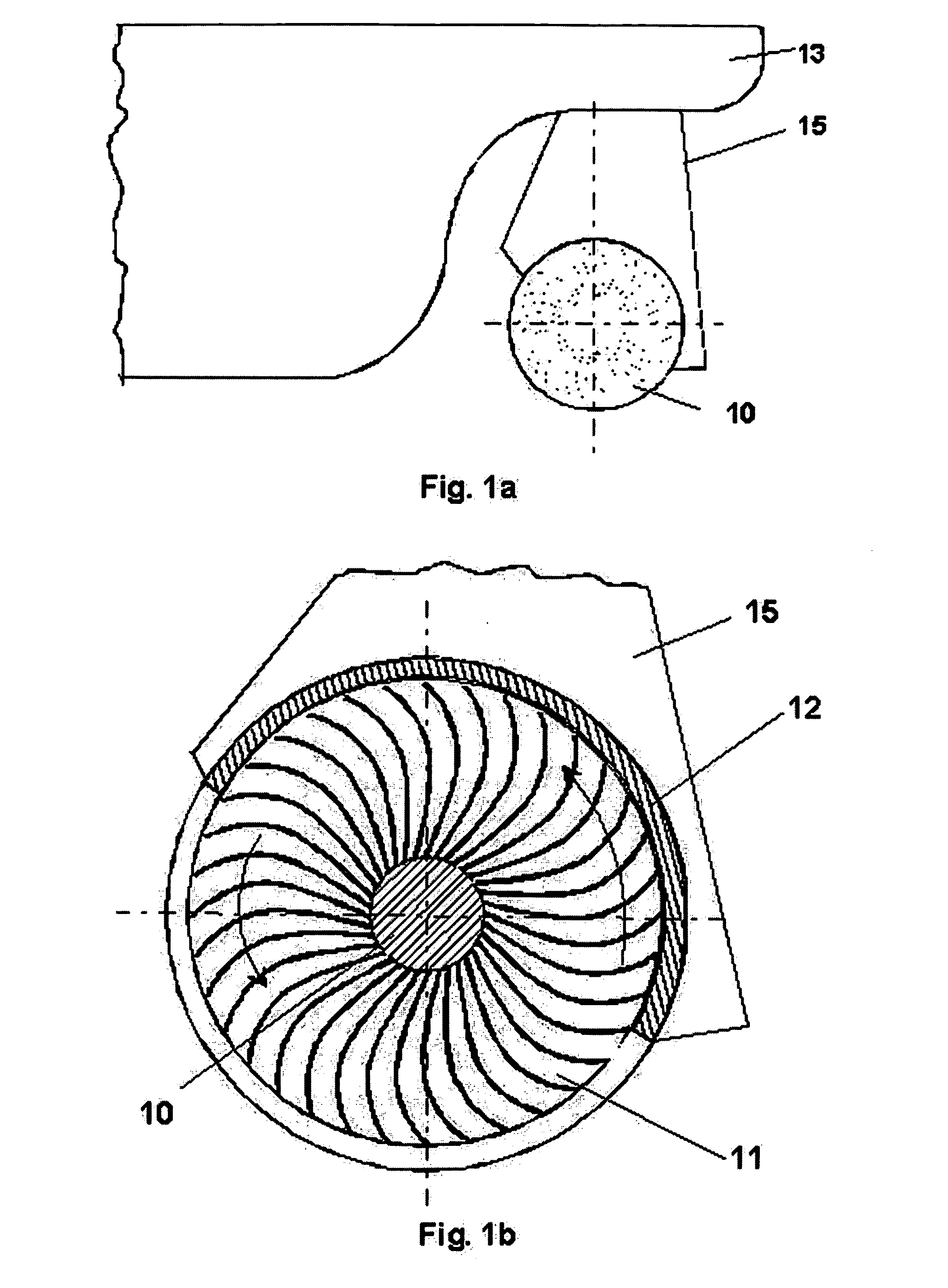

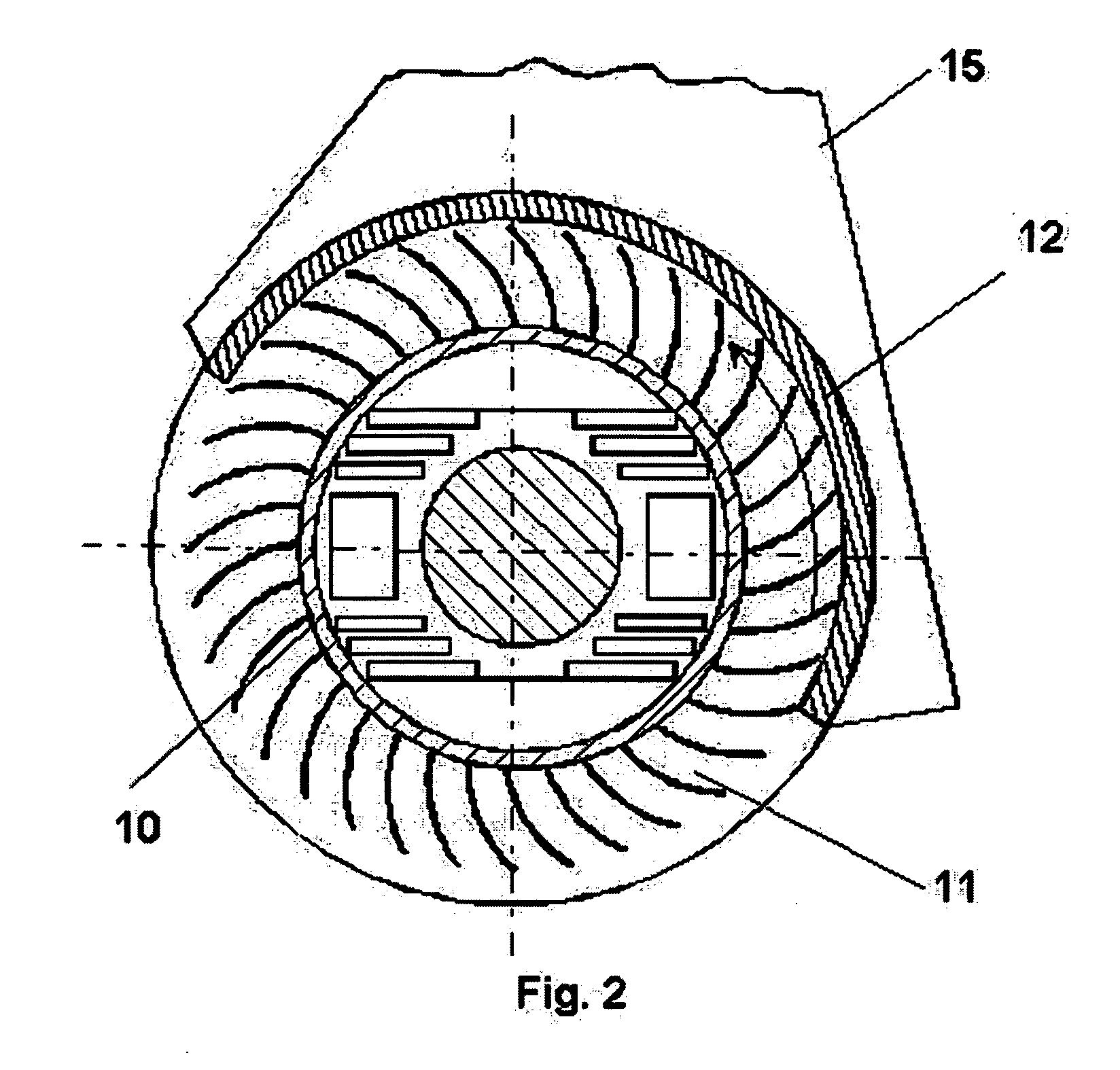

[0032]FIG. 1a shows a side view of the Centrifugal Engine mounted to the rear of a vessel. Referring additionally to FIG. 1b, an apparatus in accordance with the invention comprises a rotor shaft, a rotor 10, and a cylindrical rotor enclosure 12. The rotor is mounted to the rotor shaft and consists of a hub with radially mounted blades 11. The rotor 10 is enclosed by a cylindrical enclosure 12 in such a manner that the rotor 10 can freely spin in the enclosure 12. The rotor blades 11 form cells with the surrounding enclosure. The enclosure 12 is constructed in such a way that the rotor exposes some cells to the working fluid. The top and bottom of the rotor 10 as well as a portion of the side walls is covered by the cylindrical enclosure 12. The clearances between the rotor blades and the enclosure are kept as small as technical possible to avoid work fluid being transported through the engine. The rotor shaft that is mounted to the rotor in a fixed manner passes through the enclosu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com