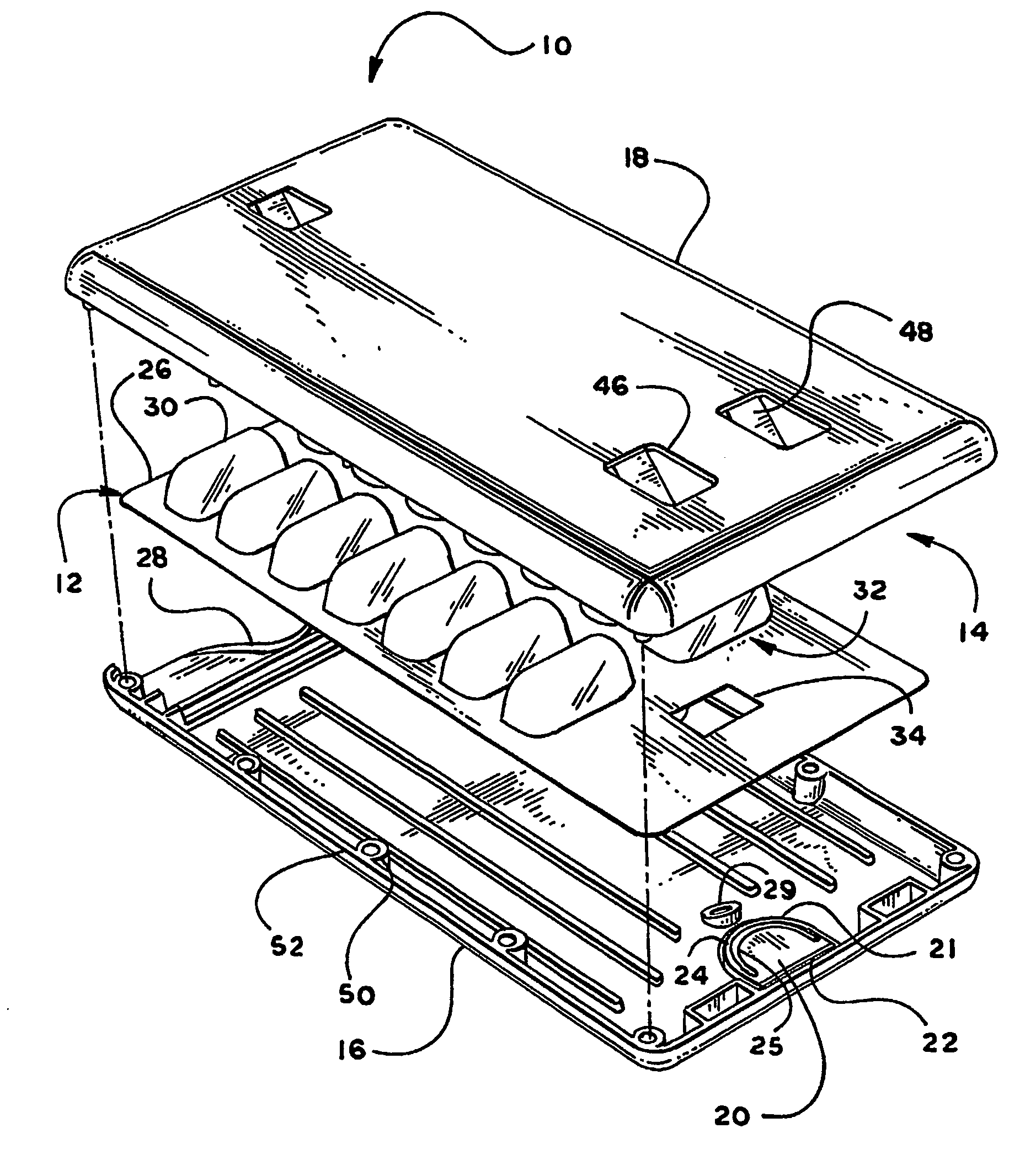

[0006] The illustrated embodiments of the present invention are directed to a child-resistant safety container for medications stored in a blister card. Generally speaking, a two-piece molded plastic container closed on three sides forms a void that receives a blister card that slidably translates through the open forth side. Appurtenants extend into the void as a means for engaging the blister card to an adjacent catch. Means for engaging include ribs and springs, attached to or formed with the molded plastic pieces as is well known to those skilled in the art, to exert a force on the card. The illustrated embodiments show two flexible springs molded on one side of the container that push the blister card against the opposite side where a catch is located and positioned to engage at least one aperture that is part of the blister card. A

retainer prevents the blister card from being fully removed; however, manipulating the

retainer with a thin device such as replacement blister card releases the first used blister card, which can then be slid out of the container. Posts molded on one piece are mated to and welded to the corresponding hollow cylinders molded on the other piece. Energy directors may weld side edges. This invention allows blister cards to be loaded into the case during manufacture, at the point of purchase or by a health care professional, or by the user at later times. It also reduces the cost of

assembly, and provides a child-resistant, re-useable

medicine dispensing case. Additional embodiments fulfill the needs for single

dose dispensing packaging.

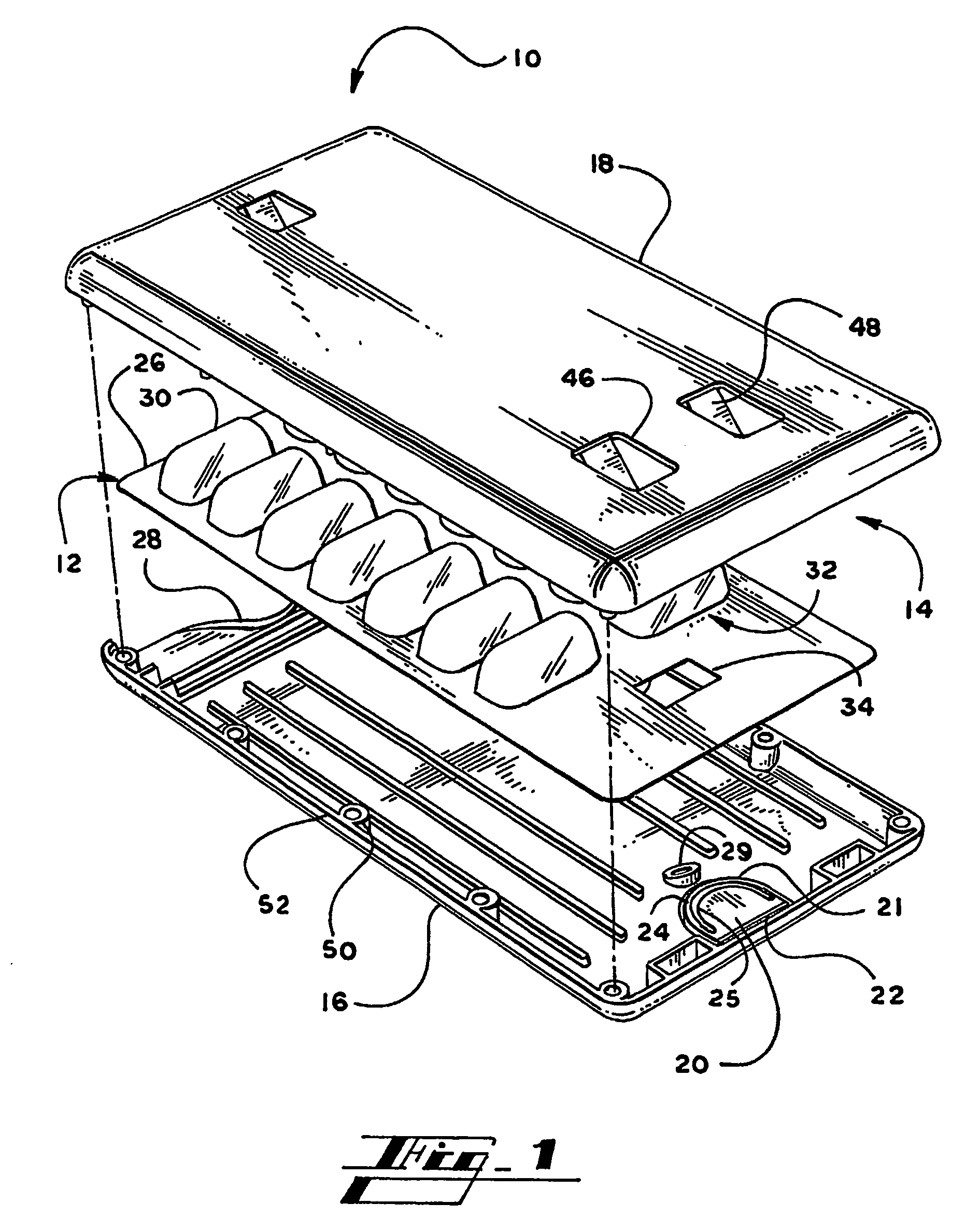

[0007] In a single

dose dispensing

package, a child-resistant case for

dispensing medications held on a blister card has a two-piece molded plastic sleeve closed on three edges. A blister card is slidable through the open fourth edge to

expose a row of blister upon a manipulation of the parts. An appurtenant, should here in the form of a dagger spring near the open edge, fits through an opening in the blister card and acts as a travel limit when the card is slid out. Additional appurtenants, such as flexible springs and rigid ribs, may be molded with or attached to a first piece and configured to force the blister card against the inside surface of whichever piece includes a molded catch or detent. The detent, shown here for purposes of teaching and not limitation on the side opposite the springs near the closed end, engages an opening in the blister card to prevent a fully inserted blister card from sliding outward. Pressing on an adjacent release distorts the blister card so that the molded catch no longer engages the opening in the blister card, which can then be removably slid outward from the container to

expose the

blisters. A ramp on the back of the catch depresses the

blister pack as it is slid inward. Posts molded on one piece are inserted into and welded to the hollow cylinders molded on the other piece. Energy directors may sonically weld side edges, as well as the posts and cylinders.

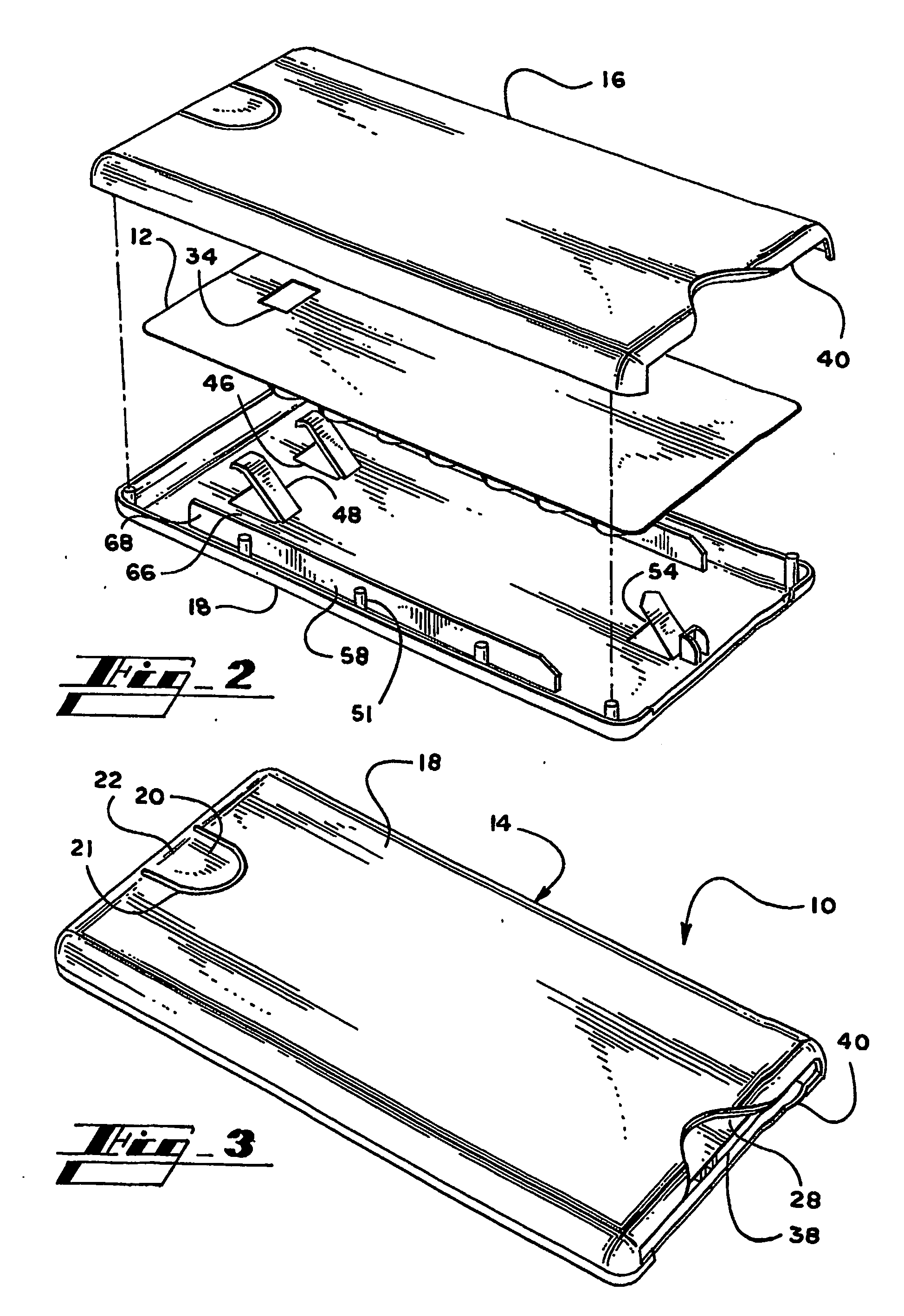

[0008] A storing and dispensing

system has a sliding blister card and a locking sleeve comprising a base and matingly connected top. The top is mated to the base by integral pins on one piece being inserted into integral cylinders on another piece and then

welding the plastic sleeve shut. The card is made from conventional blister dose

pack material—a single layer plastic top with formed alveoli holding pills or tablets on a sealed paper or foil base. The paper or foil is pushed in,

cut, or punched beneath each blister to release the respective dose. A blister card manufactured in the convention manner, configured with at least one receiving aperture and the

blisters arranged to cooperate with the internal appurtenants, provides the minimum

structural rigidity for functioning of the parts.

[0009] In practice, the blister card is placed in the sleeve opening and pushed inward past the limit spring and perhaps on sliding guides between guiding cylinders and ribs. Internal appurtenant such as springs or ribs urge the blister card toward a detent The detent or catch engages the blister card's receiving aperture to lock the card in the sleeve. To unlock the card there is provided a release. In the illustrated embodiments, manipulating the release requires pressing inward to warp a part of the card away from the catch. The warping of the card moves the receiving aperture away from the detent so that the card may be slid outward through the open end of the sleeve. Extending the card to

expose the blisters is then a matter of sliding the card outwardly in increments, or fully until a receiving aperture engages a

retainer. Reverse pressure easily slides the blister card back into the case.

[0010] Embodiments according to this invention offer at least the following advantages:

lightness in weight, resistance to tampering, child-resistance,

ease of access, excellent durability, ease of

assembly, repeated use, and excellent economy. It is also contemplated that the present invention is not limited to pharmaceutical-related goods, but is applicable to a plethora of delicate, sensitive, or unique portable goods. Other advantages of the present invention will be apparent from the following description, the accompanying drawings, and the appended claims.

Login to View More

Login to View More