Novel mineral composition

a mineral composition and mineral technology, applied in the field of mineral compositions, can solve the problems of dna modification (mutagenesis), damage to cellular structures (especially membranes), and both essential and non-essential metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

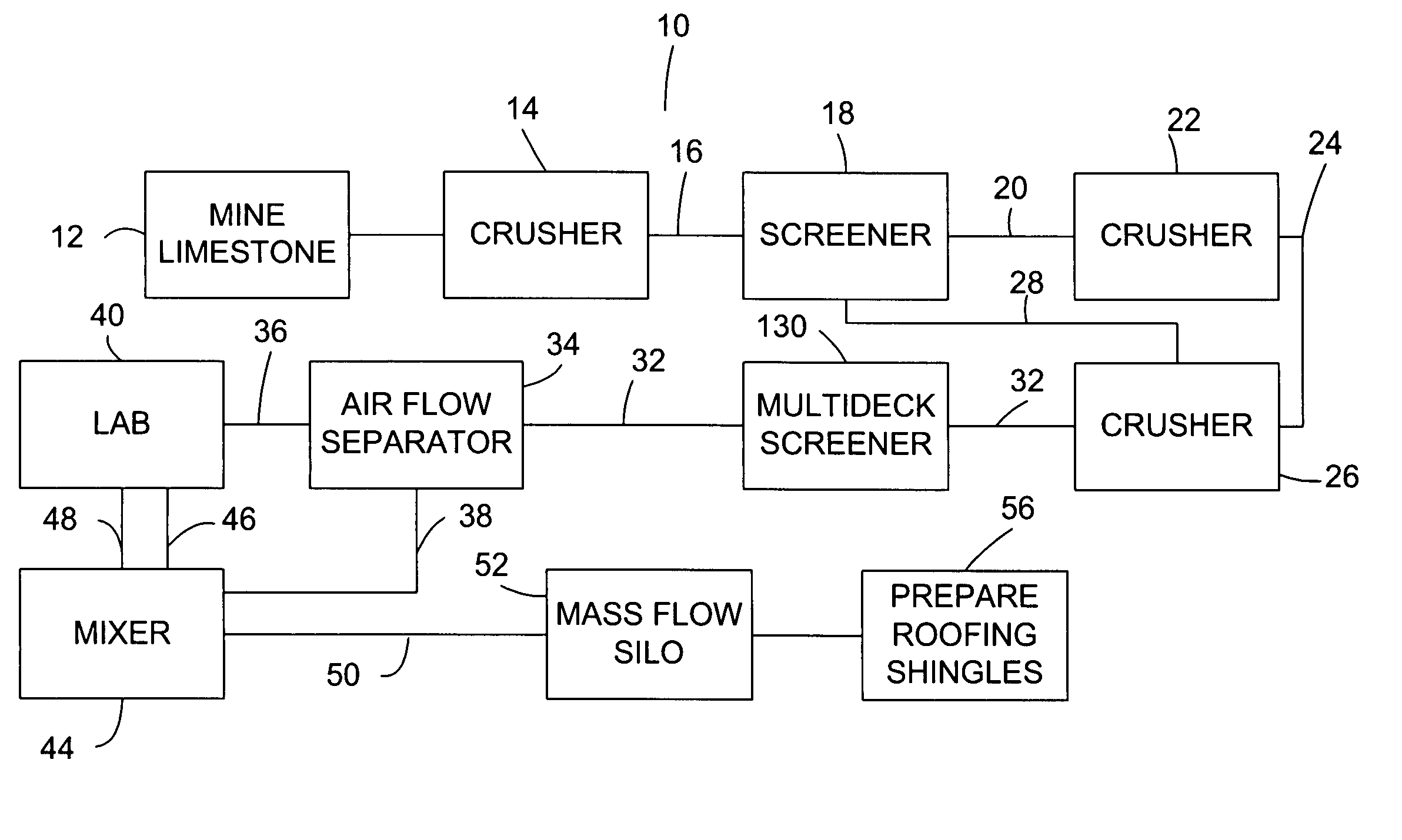

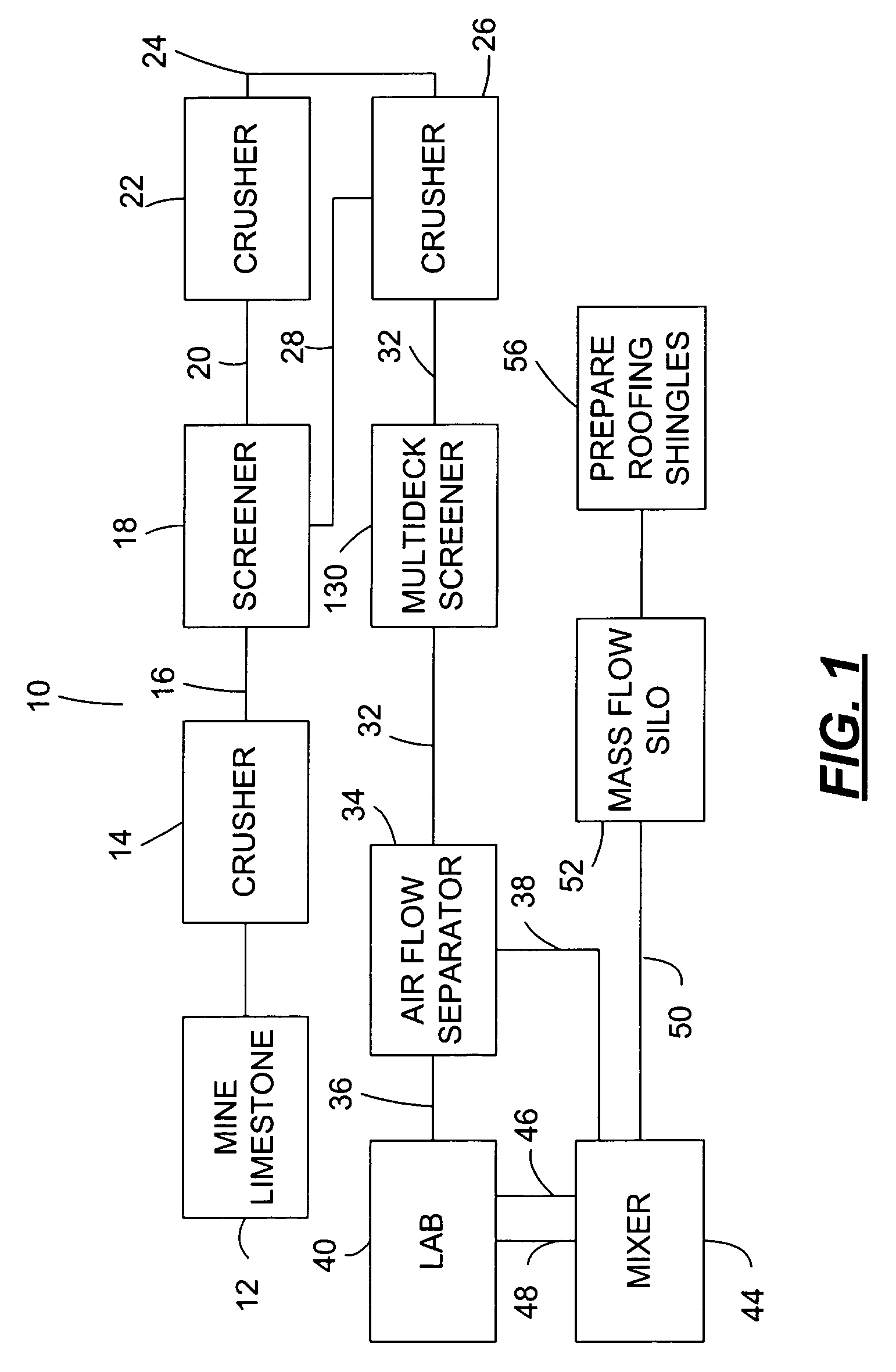

Method used

Image

Examples

examples

[0149] The following examples are used to illustrate the claimed invention but are not to be deemed limitative thereof. Unless otherwise specified, all parts are by weight, and all temperatures are in degrees Celsius.

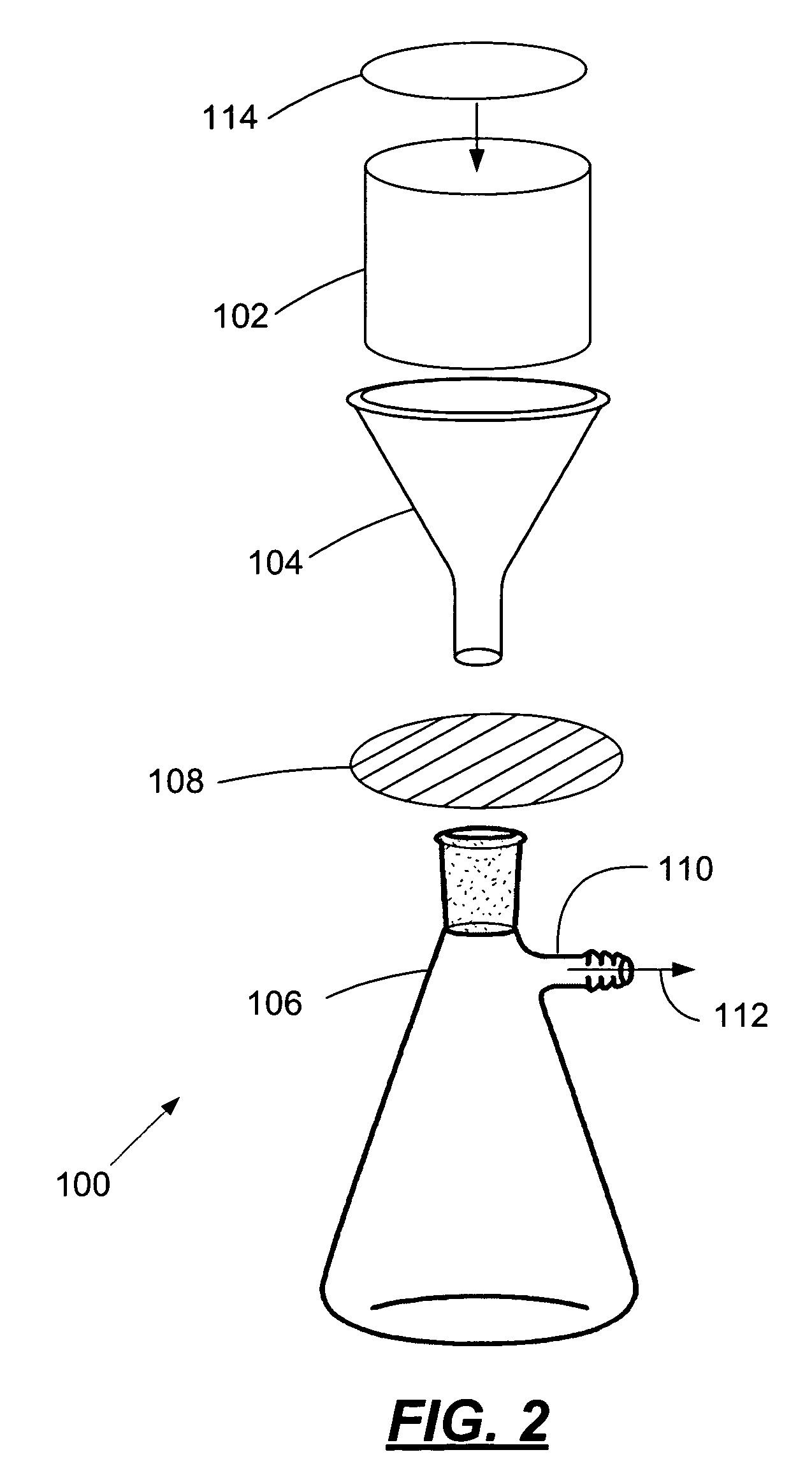

[0150] In each of the following examples, headlap granules were used to make a sample shingle, and the sample shingle was then tested for granule adhesion in accordance with ASTM Standard Test 4977-3. The procedure for making the test samples is described hereinbelow.

[0151] The test samples used to determine the adhesive characteristics of the coated limestone granule particles were constructed using a petroleum-based roofing asphalt manufactured by the Hunt Refining Company of Tuscaloosa, Alabama. This asphalt had been oxidized by blowing with air at a temperature of approximately 500 degrees Fahrenheit, to achieve a final Ring & Ball Softening Point of 215 degrees Fahrenheit (as determined by ASTM D 36) and had a Needle Penetration of between 15 decimillimeters at 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com