High energy blast explosives for confined spaces

a high-energy, confined space technology, applied in the direction of explosives, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., can solve the problems of severe ineffectiveness of weapons, increased damage, and difficulty in achieving high-energy blast blast explosives, high thermal quenching rate, and high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

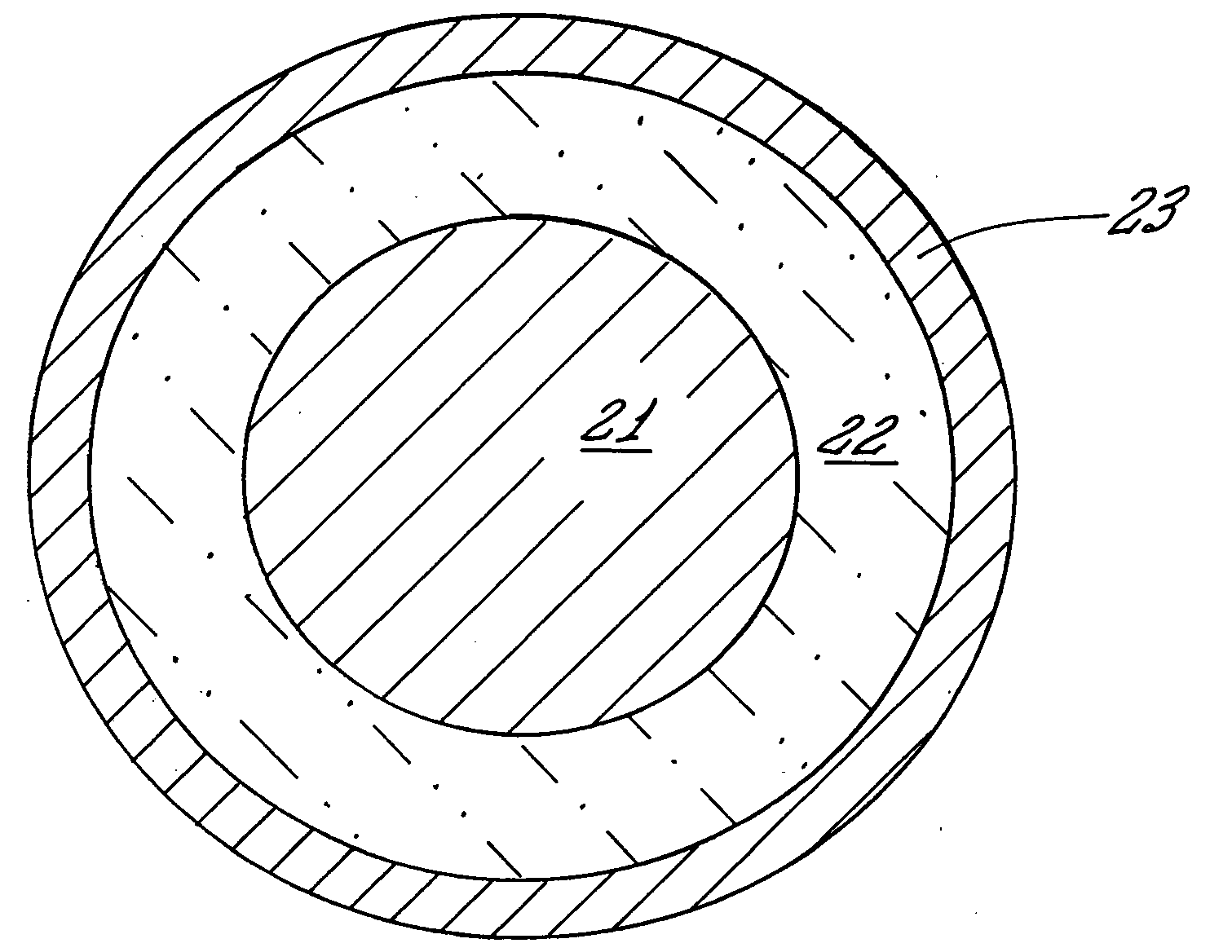

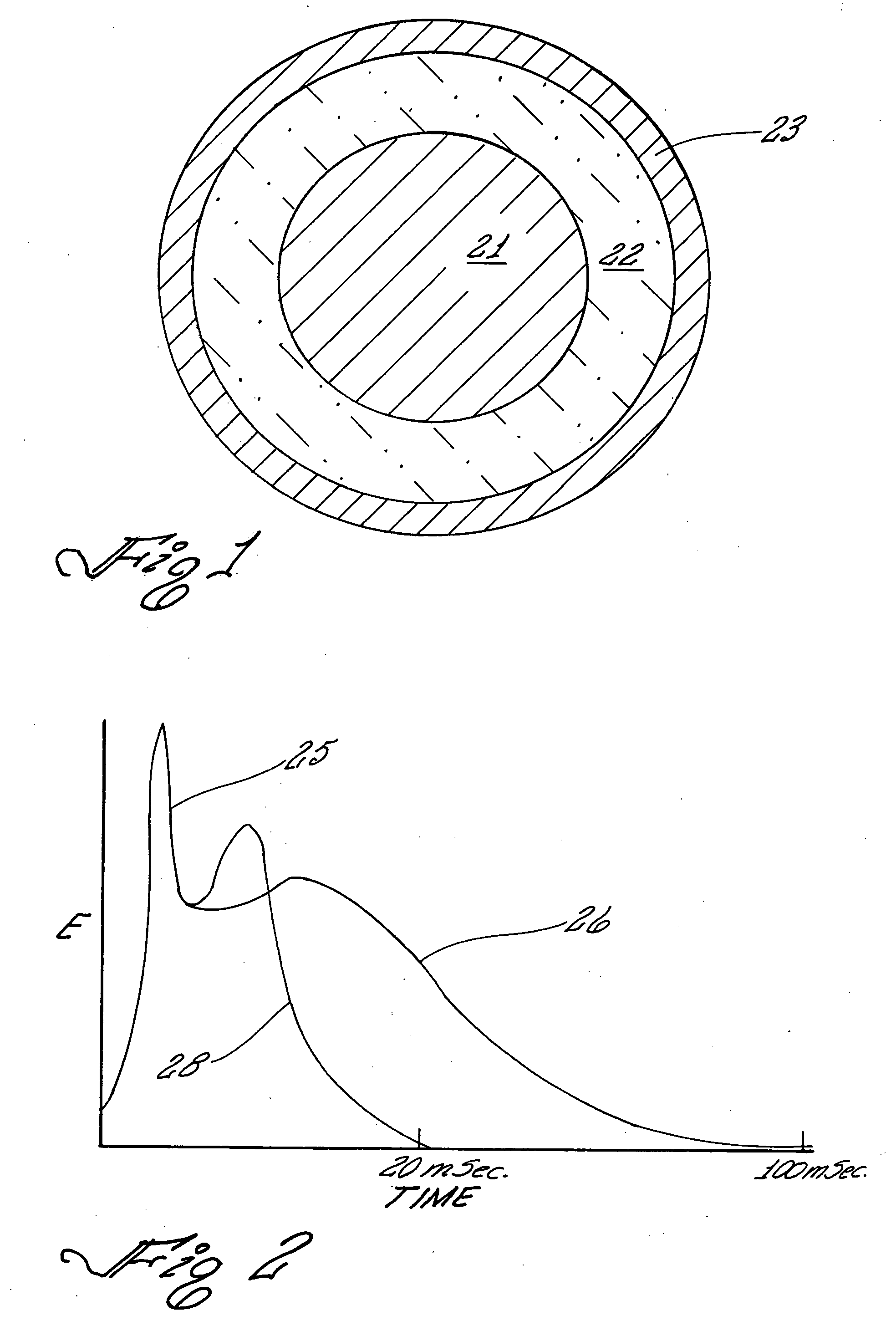

[0021] The invention disclosed herein relates to an explosive capable of enhanced combustion efficiently capable of sustaining a high pressure over a period of time in a confined environment, such as an air tight room or a cave, where oxygen may be in limited supply.

[0022] The reactive metal used in an embodiment of the present invention includes nano-sized metal particles, metastable mechanical alloys and any combination thereof. The metal fuel in these explosive formulations of the present invention incorporates nano-sized aluminum, including, for example, Alex®, boron, manganese and titanium, those having a size of about 20-500 nm. The metastable mechanical alloys include nano-sized Al—Mg, Al—Mg—H, B—Mg, Al—B,Ti—B, mixtures and H-2 and H-5 made from high energy milling. The metastable mechanical alloys include nano-crystalline metastable phases with particle sizes of about 1-50 μm. The reactive metal used also includes Ti, B or Mg. In another embodiment of the present invention,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time duration | aaaaa | aaaaa |

| ignition temperature | aaaaa | aaaaa |

| combustion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com