Automotive air conditioner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

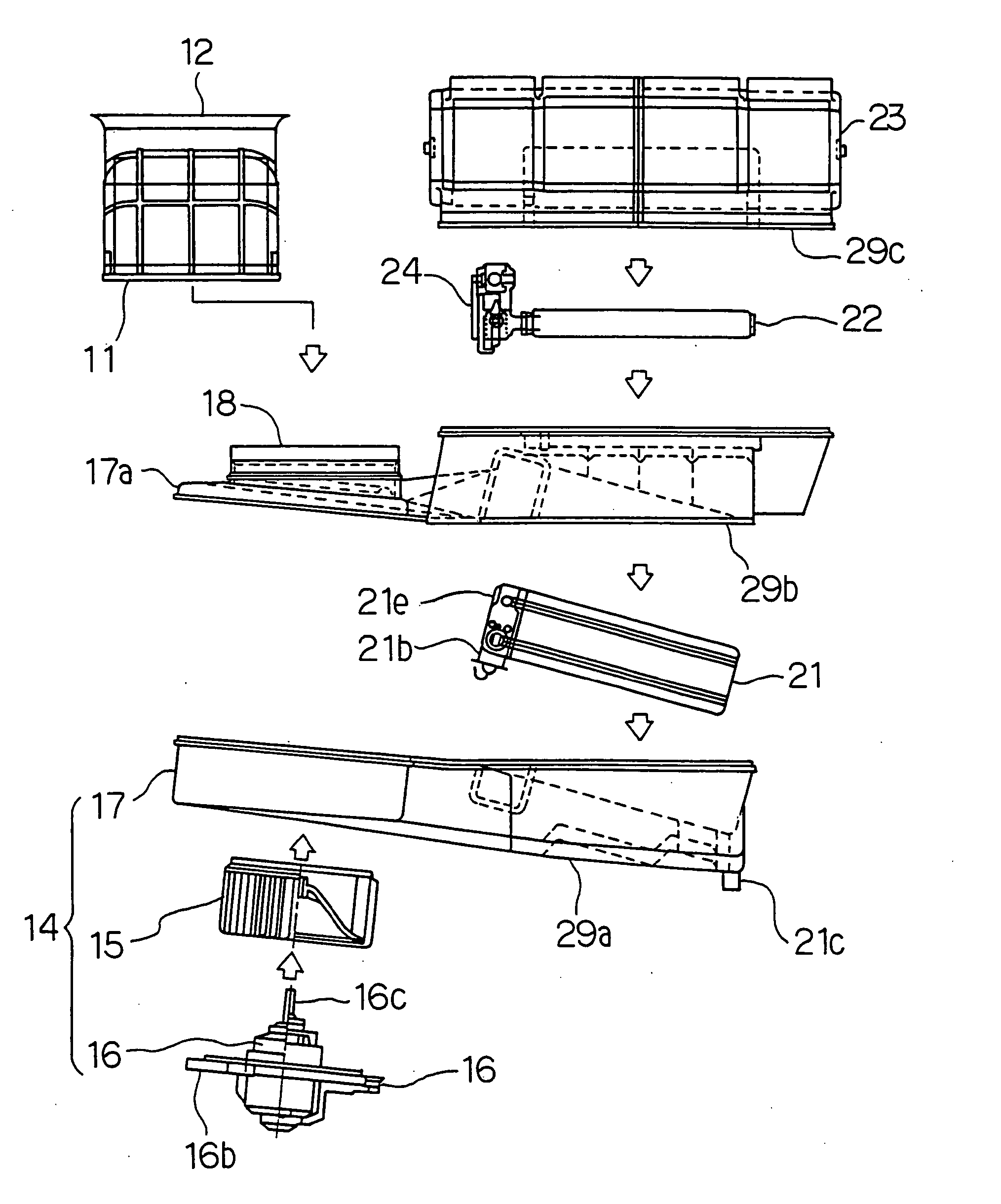

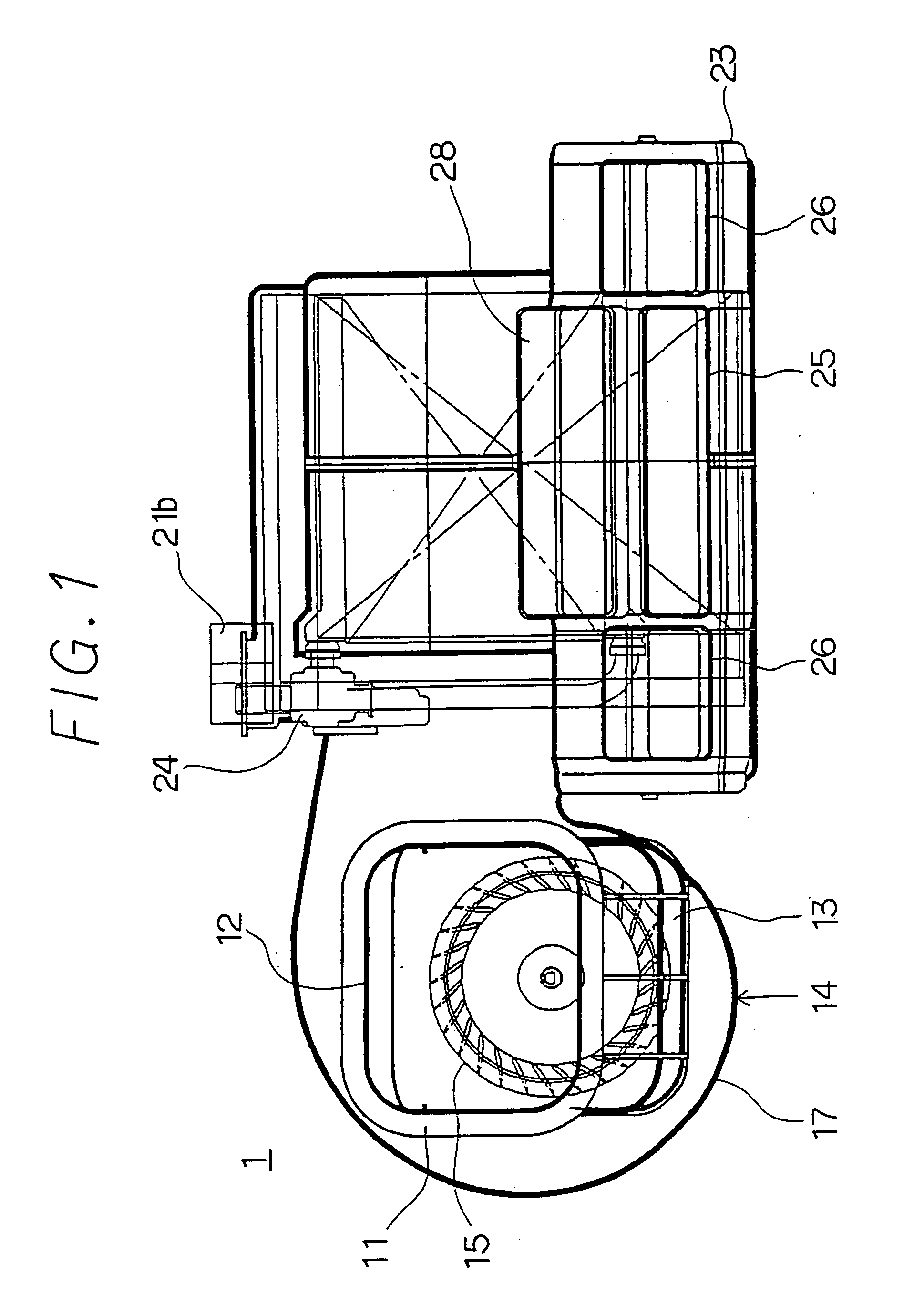

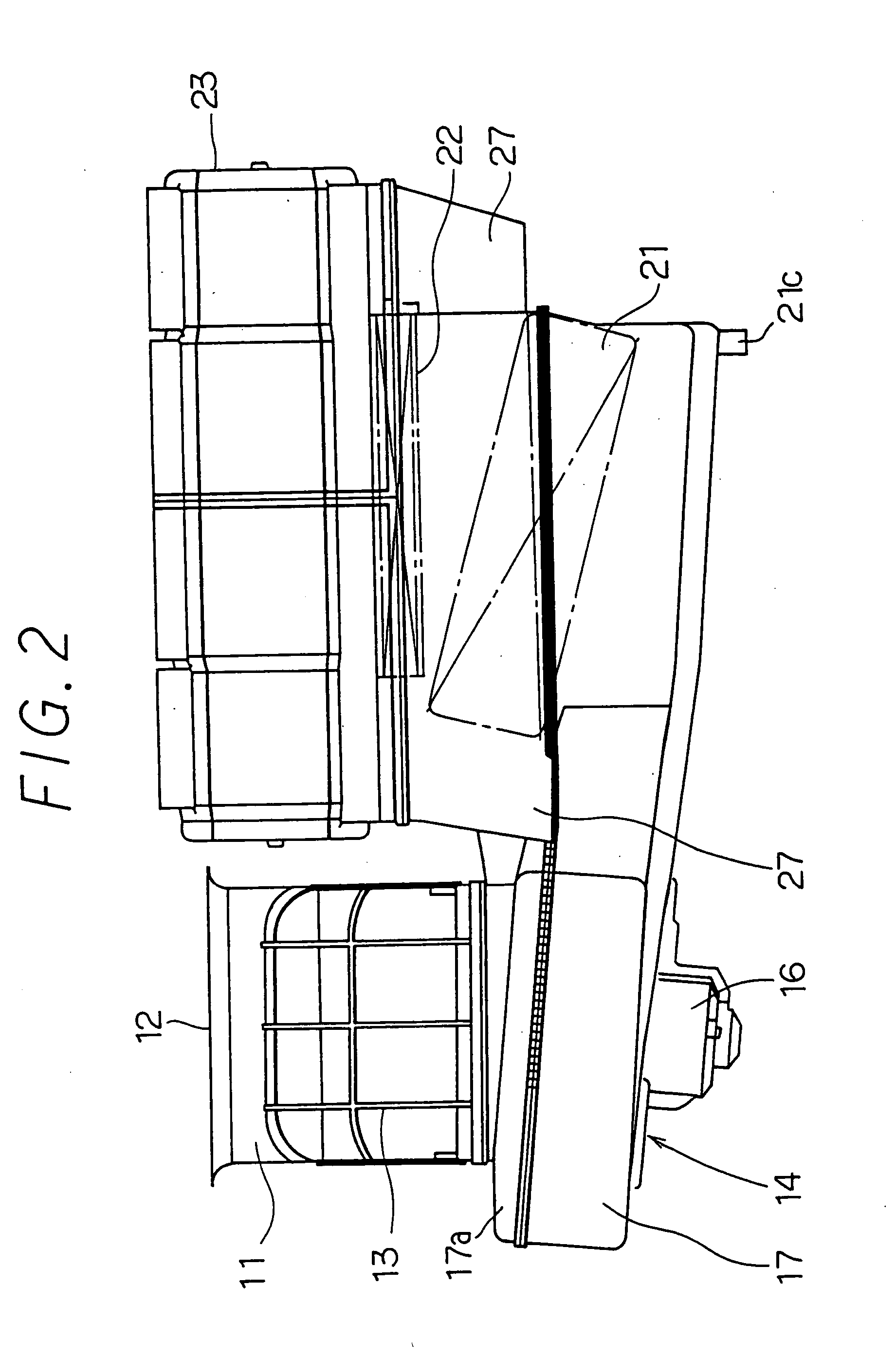

[0096] FIGS. 1 to 5 illustrate an automotive air conditioner according to a first embodiment of the present invention. Referring specifically to FIGS. 3 and 4, a vehicle includes an engine compartment A and a passenger compartment B. These compartments A and B are divided by a partition C (generally referred to as a “fire wall ” and made from an iron plate). A dashboard P is arranged within the passenger compartment B. The air conditioner comprises a fan unit 1 which is offset (to the left wheel the vehicle has a right steering wheel) from the central portion of the dashboard P in the width direction of the vehicle.

[0097] The fan unit 1 has an internal air / external air selector housing 11 arranged at its top and adapted to allow for selective introduction of internal and external airs. The internal air / external air selector housing 11 includes an external air inlet 12 and internal air inlets 13. An internal air / external air selector door (not shown) is mounted within the internal a...

embodiment 2

[0140] Referring to FIGS. 12A and 12B, the guide plate 21k has a cross shape to improve drainage of the condensed water. Specifically, the cross-shaped guide plate 21k has a flange 210k to stop the flow of the air and prevent upward flow of the air behind the flange 210k.

[0141] By this arrangement, the condensed water can more easily drop behind the flange 210k for better drainage. As an alternative, the guide plate 21k may have a T-shape to facilitate drainage of the condensed water.

[0142]FIG. 13 shows effects of the second embodiment. The vertical axis indicates the flow of air when 12 volts are applied to the fan motor 16 (see FIG. 5). The horizontal axis indicates the angle of inclination of the evaporator 21 with respect to a horizontal plane.

[0143] Referring to FIG. 13, the solid line shows the case in which the cross-shaped guide plates 21k of the second embodiment are provided. The broken line shows the case in which no cross-shaped guide plate 21k is provided.

[0144] As ...

embodiment 3

[0146] Referring to FIG. 14, the guide plates 21k are flat and inclined with respect to the direction of flow of the air. The guide plate 21k has a rear surface 211k. The upward flow of the air is retarded behind the rear surface 211k so as to allow the condensed water to easily drop behind the rear surface of each guide plate 21k.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com