Articulated floor scrubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

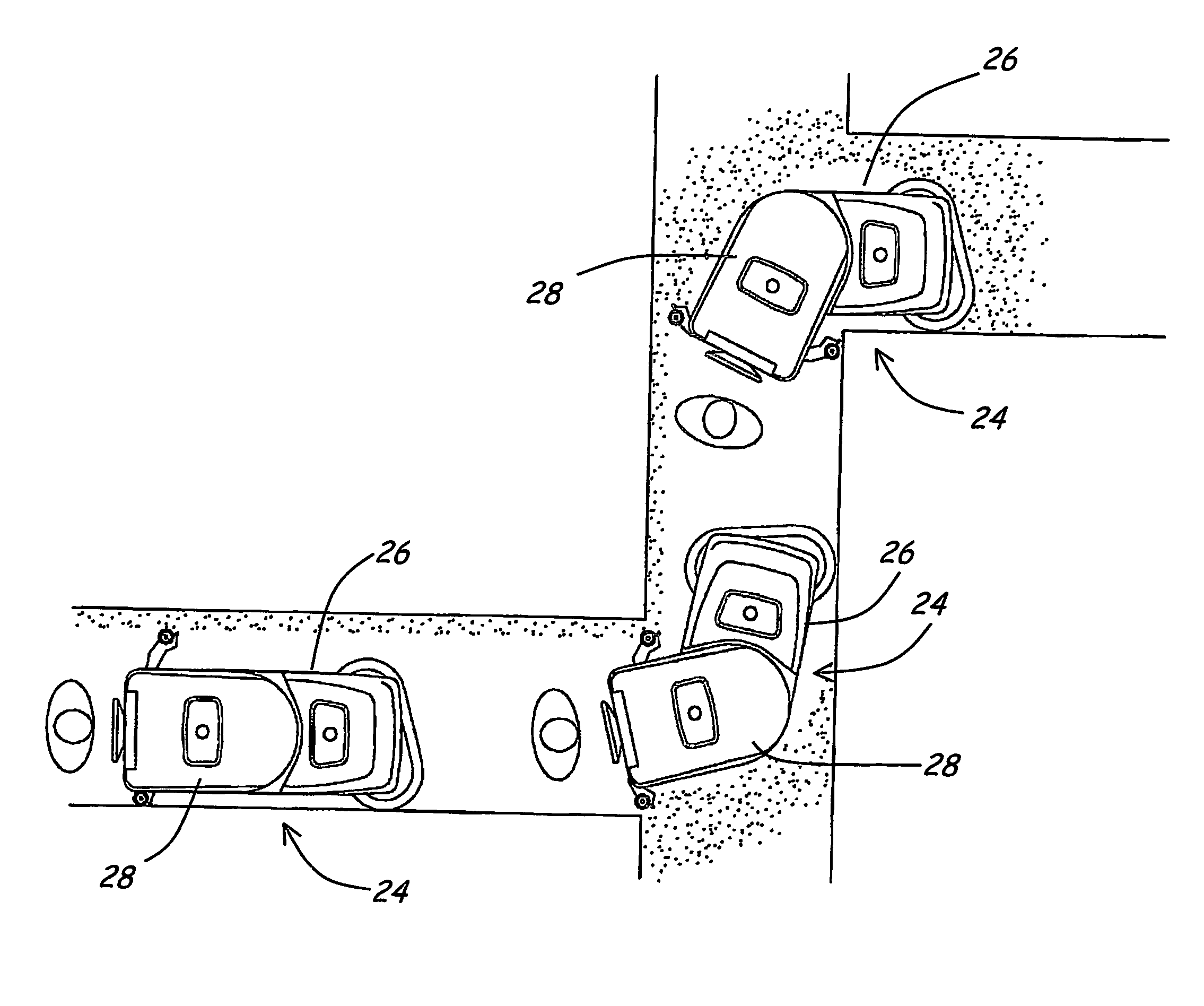

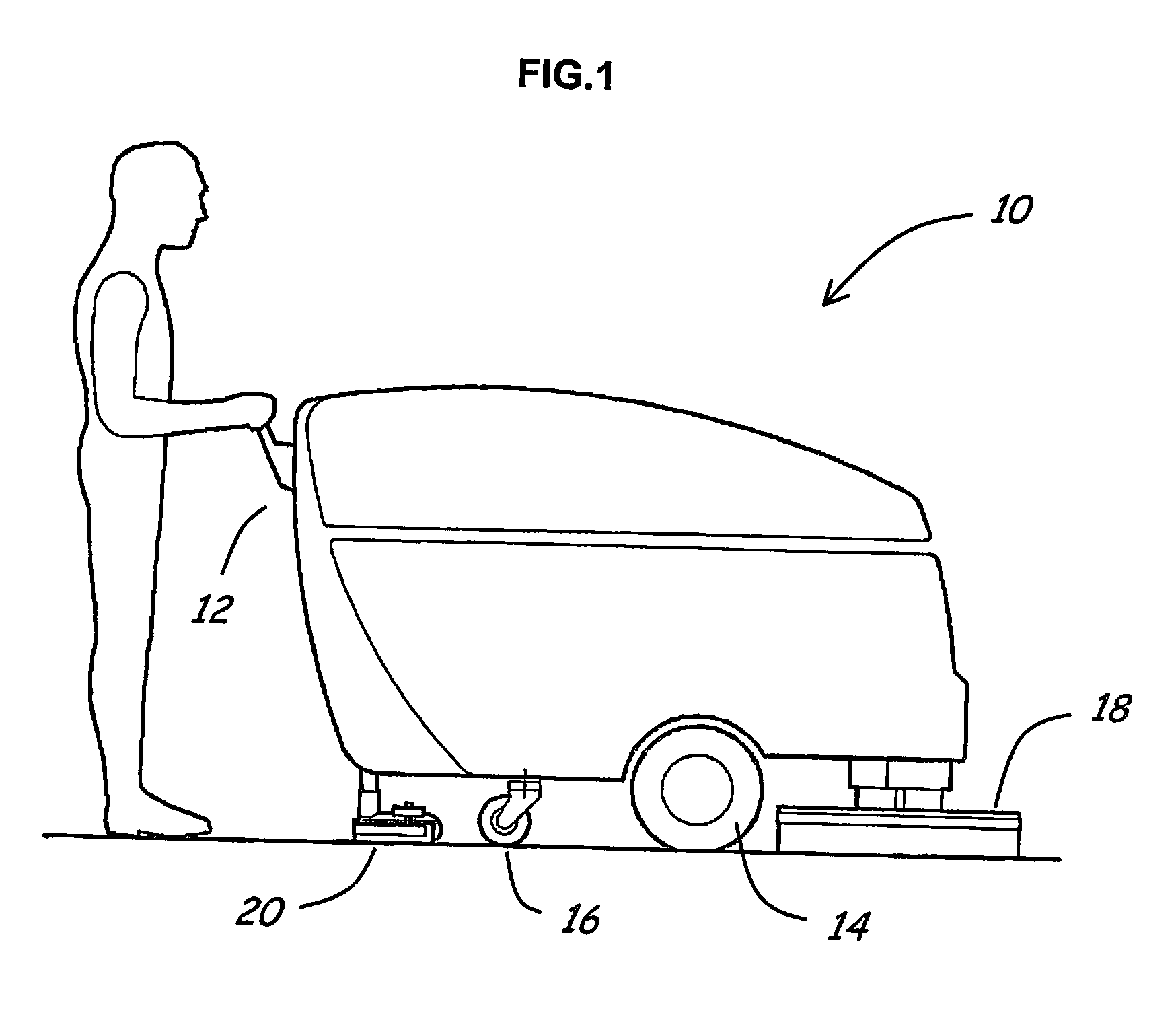

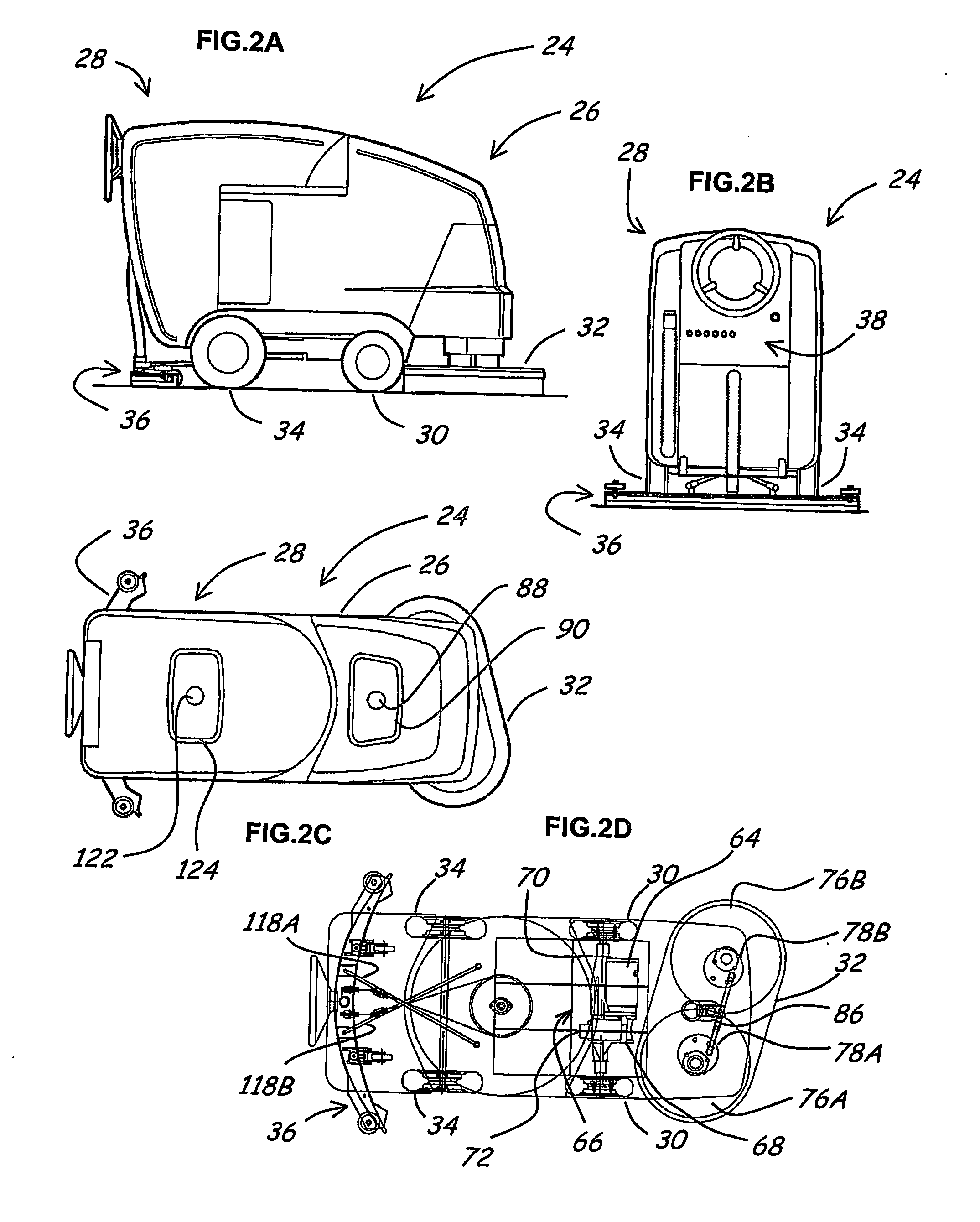

[0030] With reference to FIGS. 2A-2C, an embodiment of a rear-operated articulated scrubber 24 is described. The scrubber 24 comprises a front portion 26 and a rear portion 28 that is pivotally attached to the front portion 26. Associated with the front portion 26 is a pair of non-steerable front wheels 30 and a scrub head 32. Associated with the rear portion 28 is a pair of non-steerable rear wheels 34 and a vacuum squeegee assembly 36. Also associated with the rear portion 28 is an operator interface 38 that allows an operator to steer the scrubber 24 and otherwise control the scrubber 24.

[0031] With reference to FIG. 3, the scrubber 24 further comprises a solution tank 40 for holding a cleaning solution (e.g., water, soap and water etc.) and a recovery tank 42 for holding whatever cleaning solution and entrained debris that the vacuum squeegee 36 picks up from a floor. The solution tank 40 is associated with the front portion 26 of the scrubber 24. The recovery tank 42 is associ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com