Thermosiphon having improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

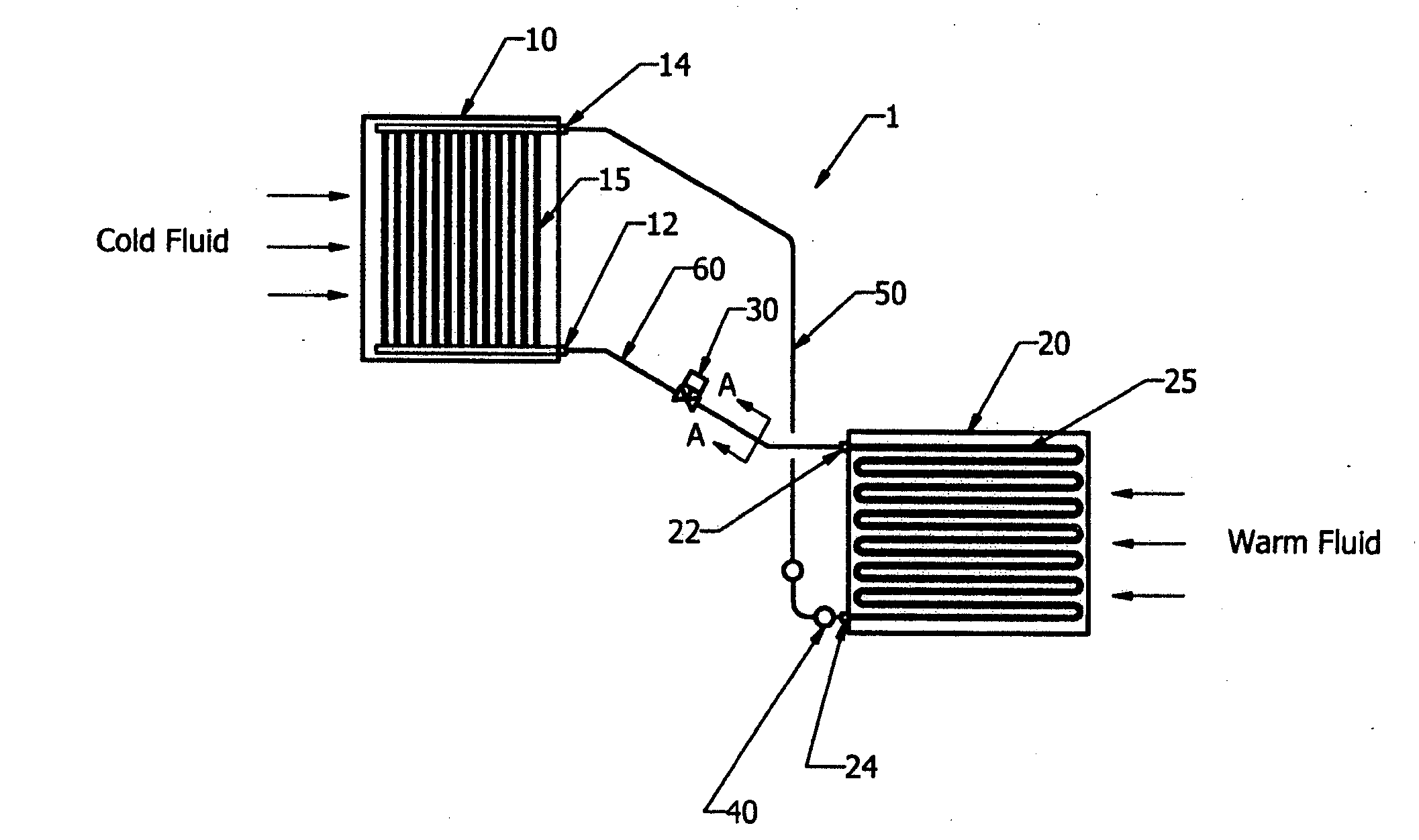

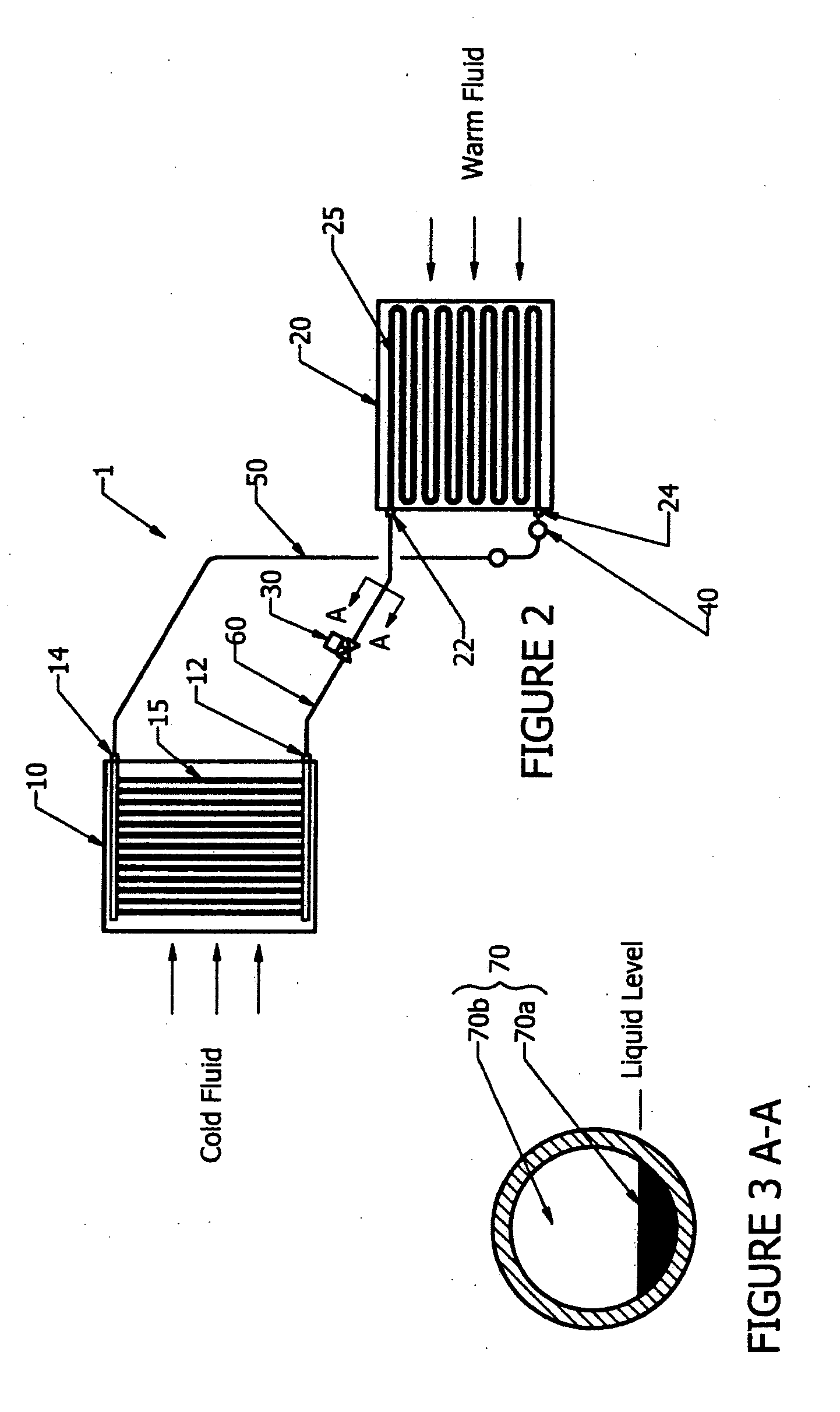

[0035]FIG. 2 shows the thermosiphon 1 of the present invention. The thermosiphon 1 contains a fluid 70, which is best seen in FIG. 3, under two different phases: liquid 70a and gaseous 70b. When the thermosiphon is not functioning, the liquid fluid 70a rests at the bottom of an evaporator 20. When functioning, the evaporator 20 exchanges heat by convection with the surrounding warm fluid that moves through it. As the liquid fluid 70a starts to evaporate and becomes gaseous, it exits evaporator outlet 24 and rises via the conduit 50 to the condenser 10 through its inlet 14. Since condenser 10 also exchanges heat by convection with the surrounding cold fluid that moves through it, the gaseous fluid 70b condensates on the walls of the condenser 10. By gravity, the liquid fluid 70a falls to the bottom of the condenser 10 where it exits through the condenser outlet 12. Normally in a thermosiphon, to further save energy by not having to use a pump, the condenser outlet 12 is located highe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com