Substrate processing apparatus

a processing apparatus and substrate technology, applied in the direction of photomechanical apparatus, instruments, printers, etc., can solve the problems of contaminated substrate edges, affecting the cleaning effect, so as to achieve easy control and high cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

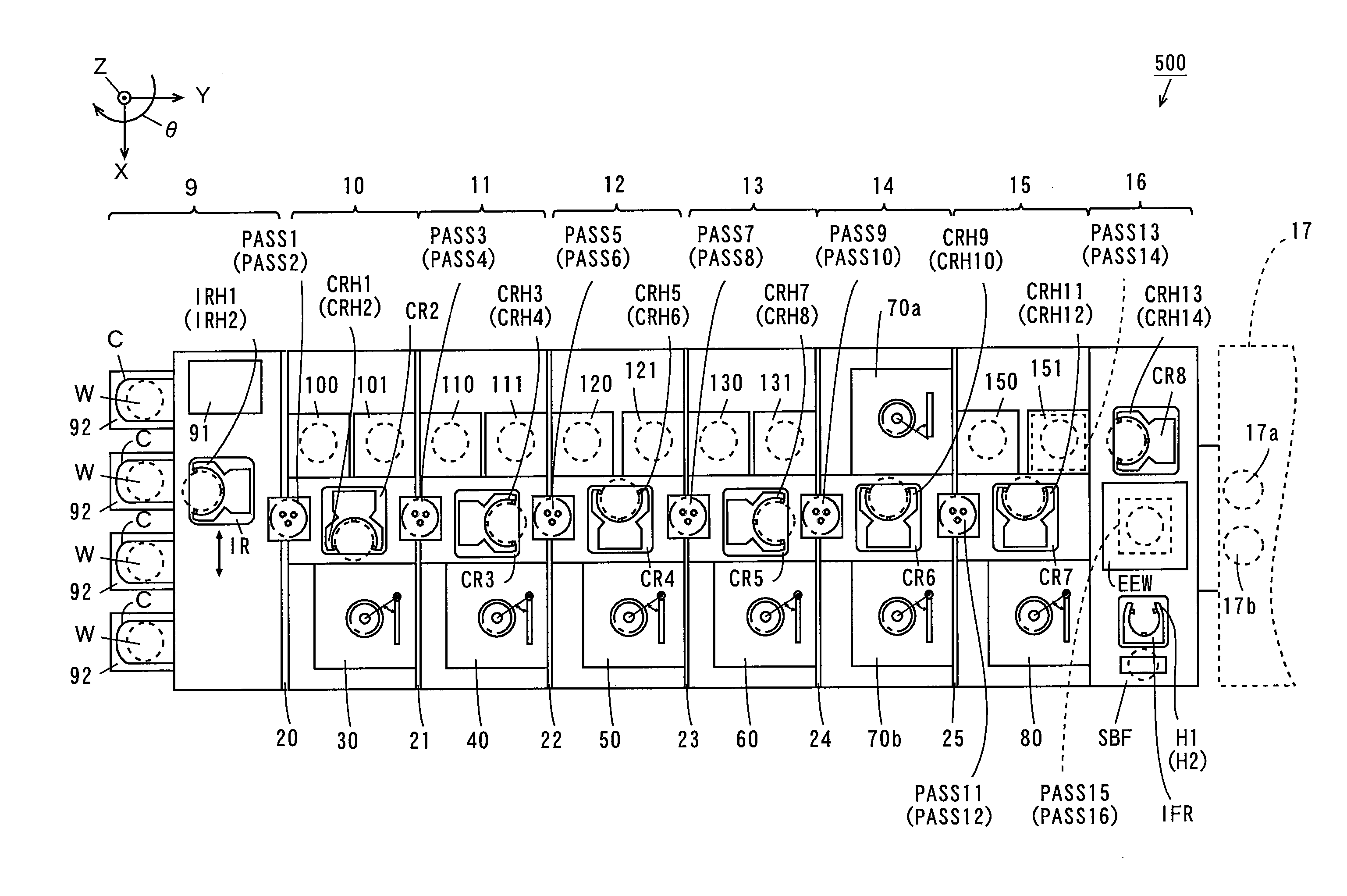

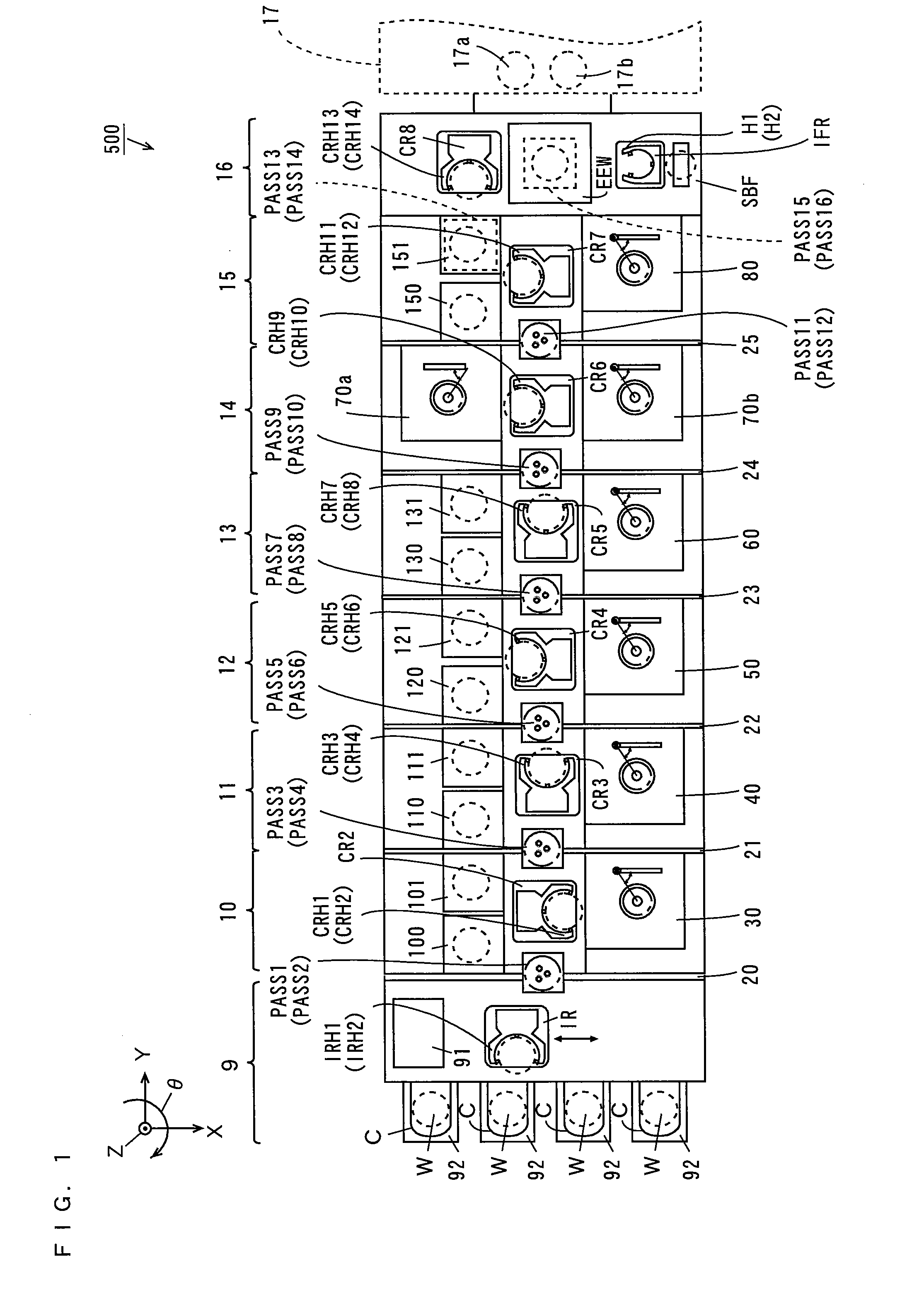

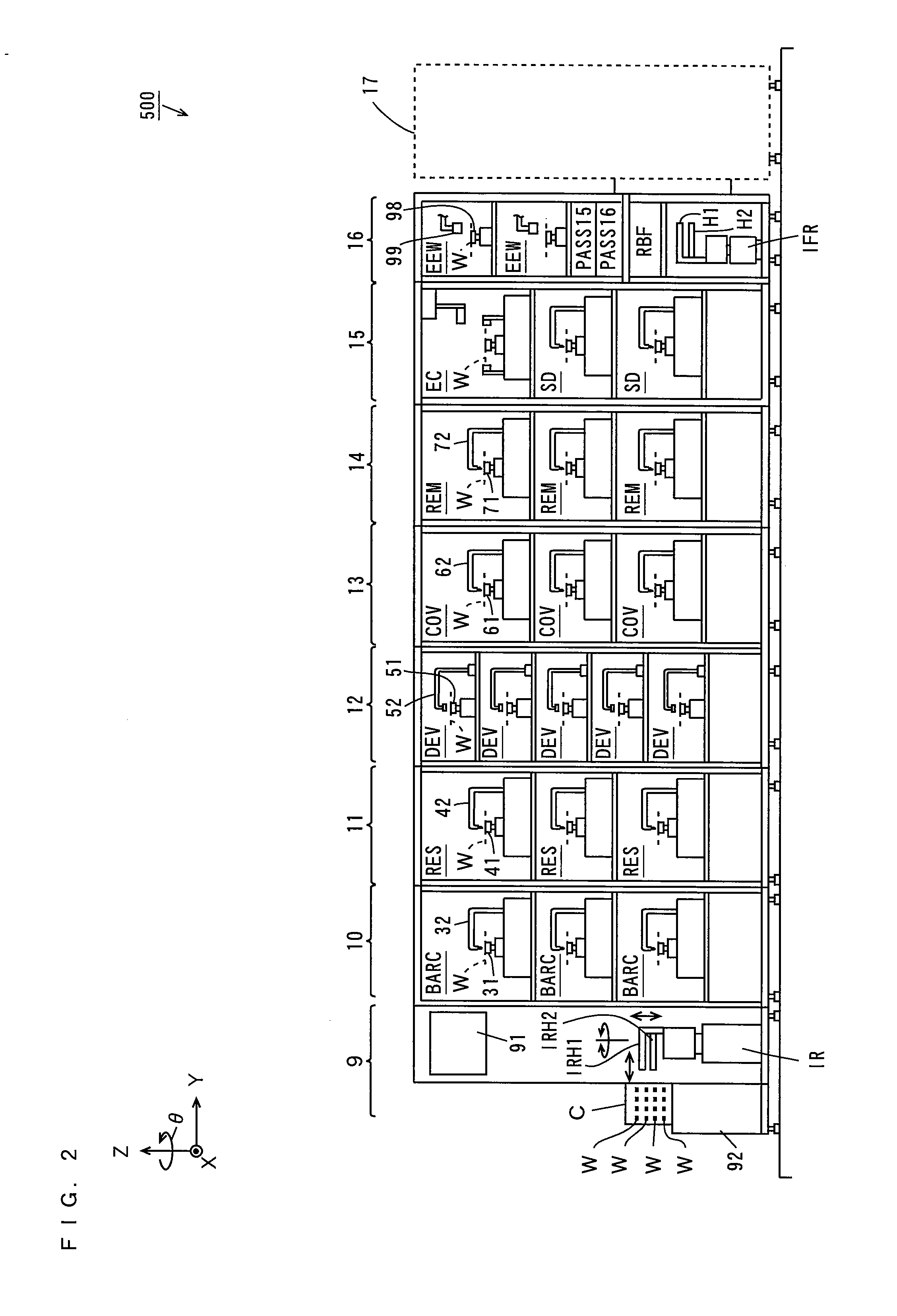

[0096] A substrate processing apparatus according to an embodiment of the present invention will be described with reference to the drawings. In the following description, a substrate refers to a semiconductor substrate, a substrate for a liquid crystal display, a substrate for a plasma display, a glass substrate for a photomask, a substrate for an optical disk, a substrate for a magnetic disk, a substrate for a magneto-optical disk, a substrate for a photomask, or the like, and the substrate contains silicon (Si).

[0097] The following drawings are accompanied by arrows that respectively indicate X, Y, and Z directions perpendicular to one another for clarity of a positional relationship. The X and Y directions are perpendicular to each other within a horizontal plane, and the Z direction corresponds to a vertical direction. In each of the directions, the direction of the arrow is defined as a +direction, and the opposite direction is defined as a −direction. A rotation direction ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| speeds | aaaaa | aaaaa |

| photosensitive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com