System for Immediately Placing a Non-Occlusive Dental Implant Prosthesis

a dental implant and immediate placement technology, applied in dental prosthetics, dentistry, medical science, etc., can solve the problems of multiple surgical procedures, unsatisfactory for patients, and unsightly gaps or otherwise unaesthetic appearance of patients, so as to reduce the amount of work, time and expense.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

case i

[0039] Case I

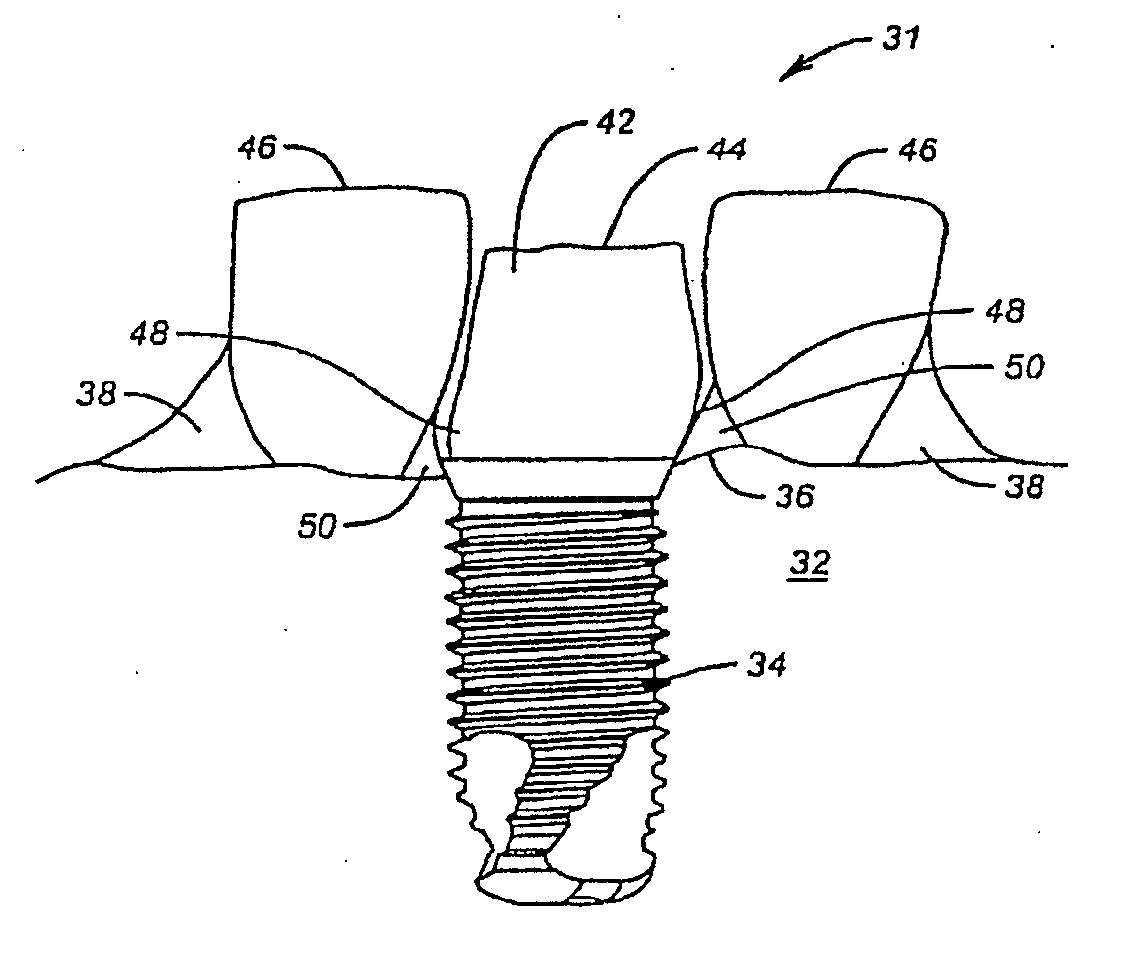

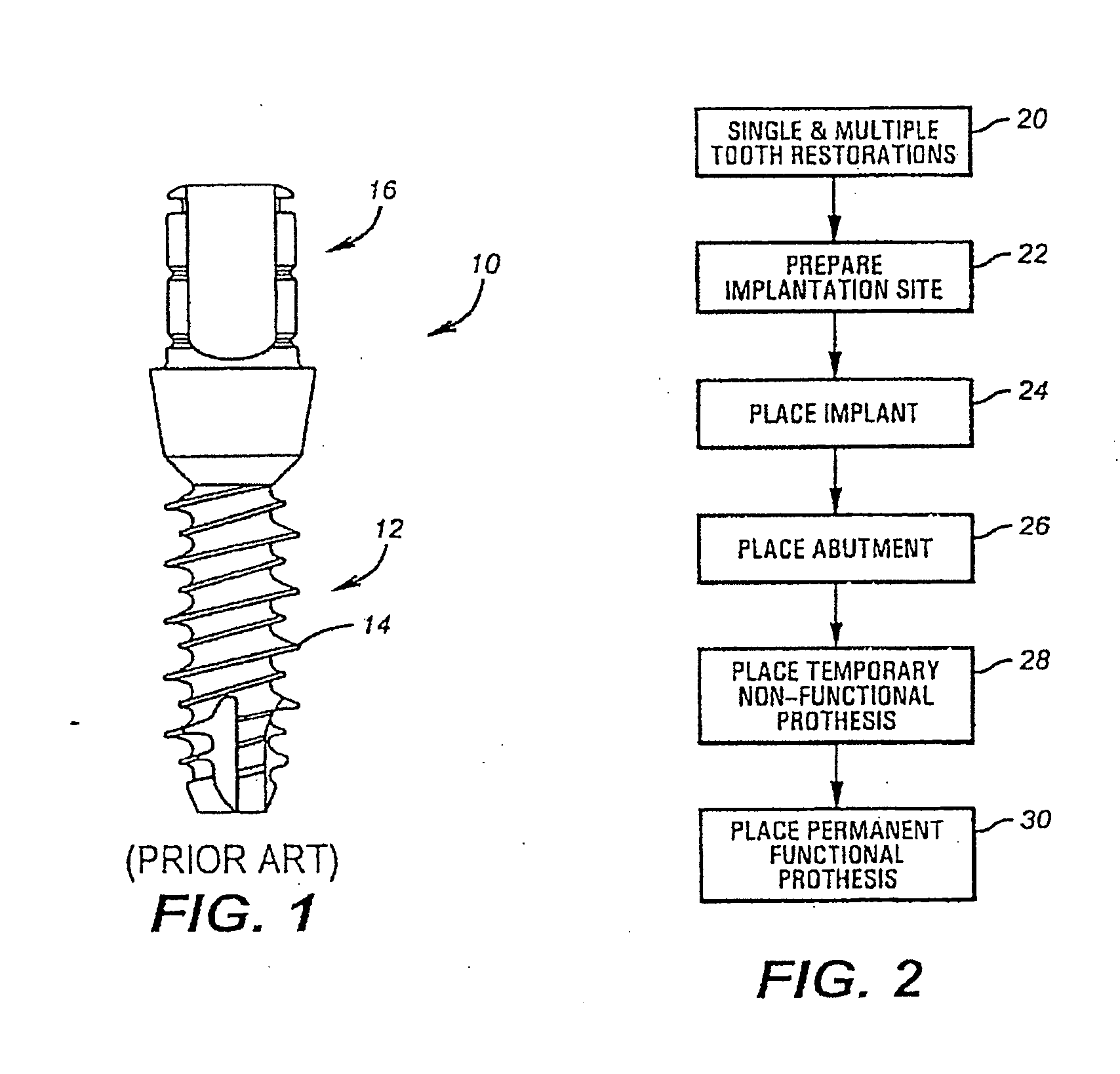

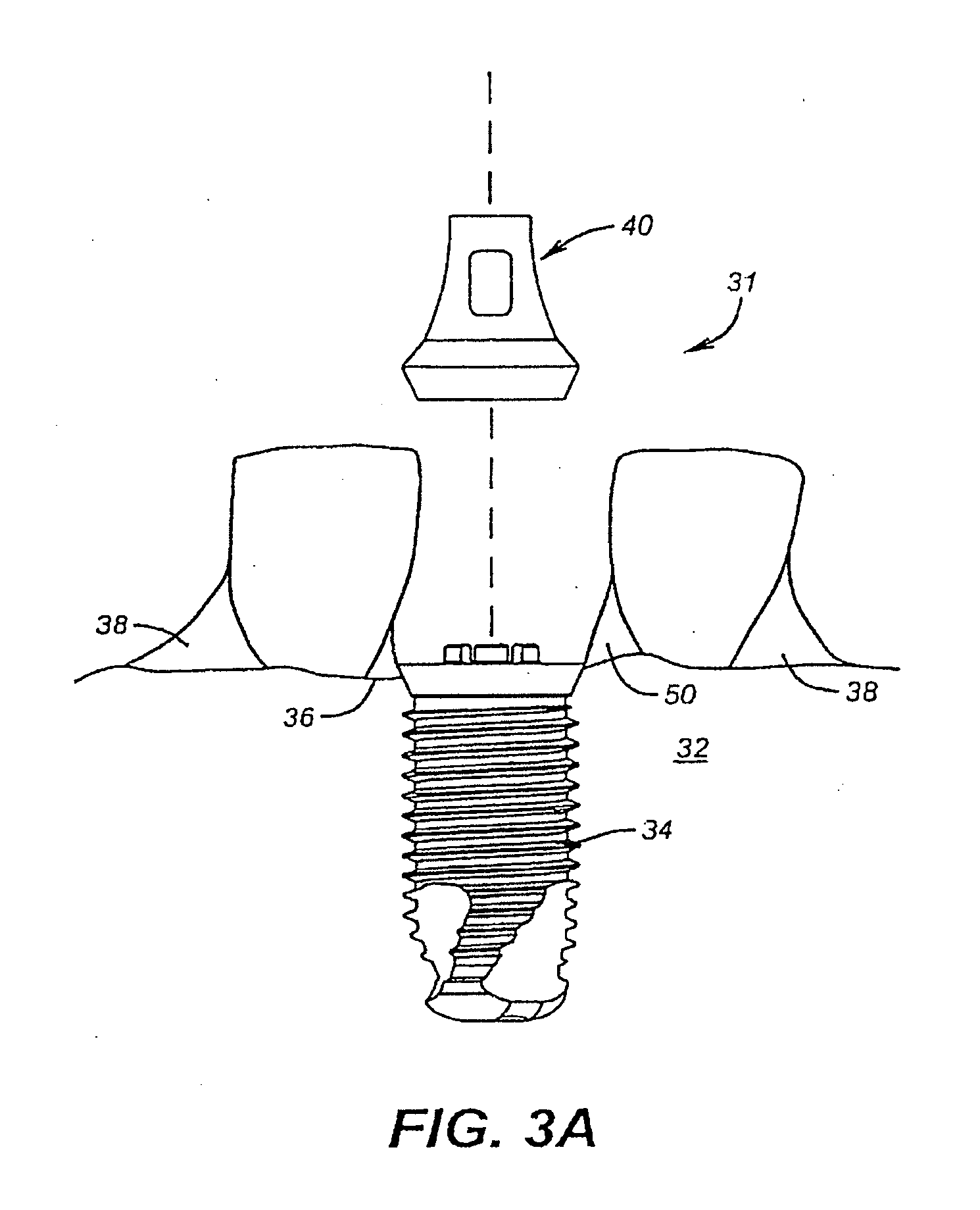

[0040] A 74-year old female had a fractured, non-salvageable first premolar. The tooth was gently elevated, keeping the soft tissue and hard tissue contours intact. There was no elevation of the soft tissue. The socket site was checked to make sure the buccal plate was intact. Direct visualization and palpation were used to identify the inter-septal buccal plate rim. In this case, the site was prepared via harvest instrumentation. The platform of the implant was set approximately 1-1.5 mm below the level on the inter-septal bone; such placement ensured the shoulder of a 2 mm abutment to be approximately 1 mm below the level of gingival cuff rim. This placement also ensured that the soft tissue would be supported to maintain its position and would allow for maximum emergence of the temporary prosthesis (or provisional). The temporary prosthesis was seated with temporary cement and taken out of occlusion. It was then allowed to heal for 16 weeks. After the healing period,...

case ii

[0041] Case II

[0042] A 47-year old man had tooth #9 that was super-erupted and mobile. Due to his present occupation, aesthetics and a quick remedy were necessary. The tooth was atraumatically removed and the socket site debrided. The position and loss of the gingiva in relation to the adjacent teeth was important here. The implantation site was prepared in a sequential fashion, utilizing drills and hand instrumentation. The implant was then seated in place, positioning the platform approximately 1-1.5 mm below the level of crestal bone. Here, the width of the socket determined the diameter of the implant, and care was taken not to perforate the buccal plate. The abutment was seated to place, the shoulder being approximately 1 mm below the crest of the gingival collar. The temporary prosthesis was placed and positioned to be out of centric occlusion and excursive movement. The tissue and implant was allowed to heal. After the normal healing time had transpired, the implant was resto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com