Rotary Blood Pump

a rotary, blood pump technology, applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of hemolysis or thrombosis, design a more perfect blood pump, passing through the pump, etc., to achieve efficient pumping of blood through the circulatory system of patients, reduce power consumption, and minimize damage to patients' blood.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

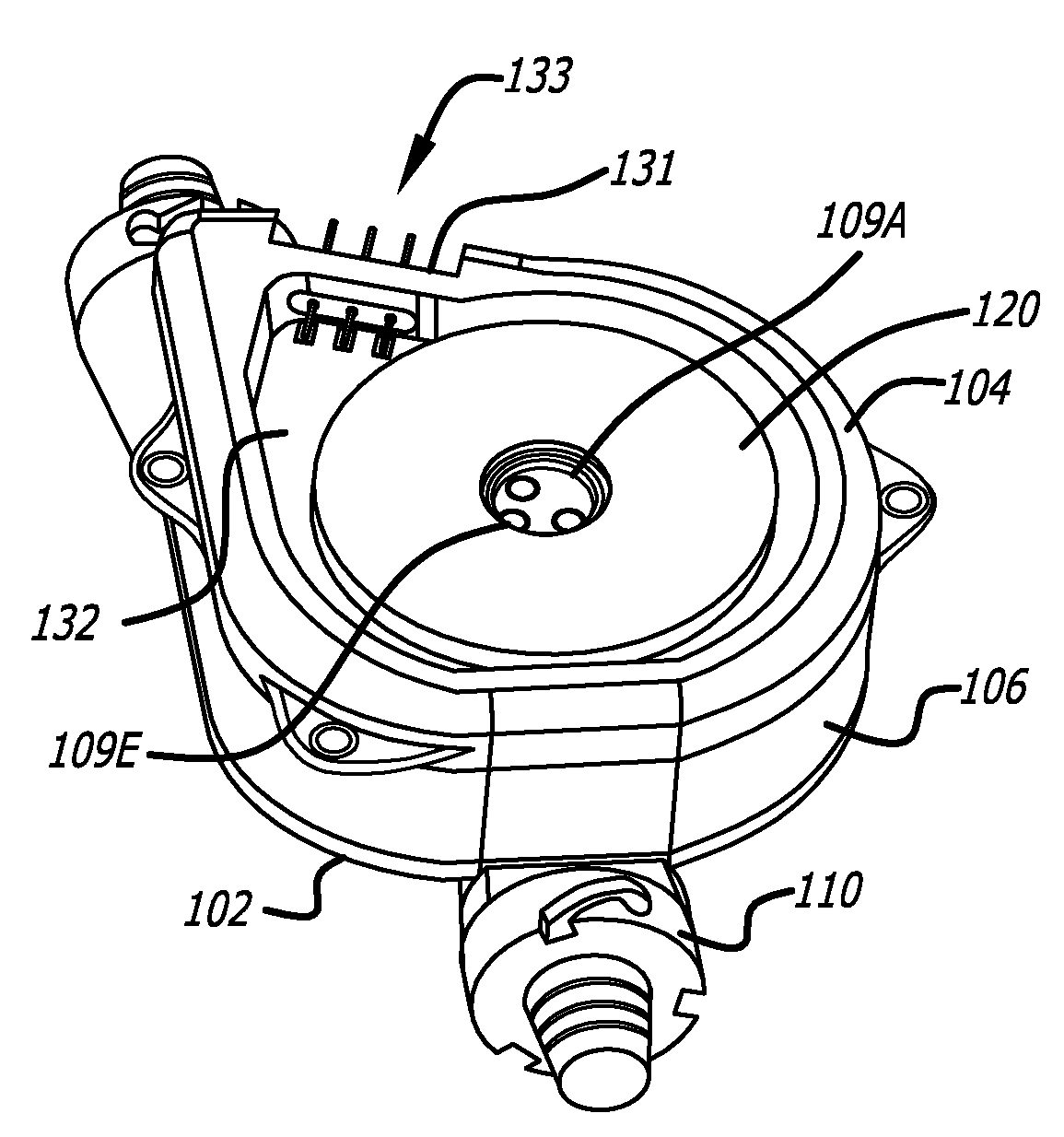

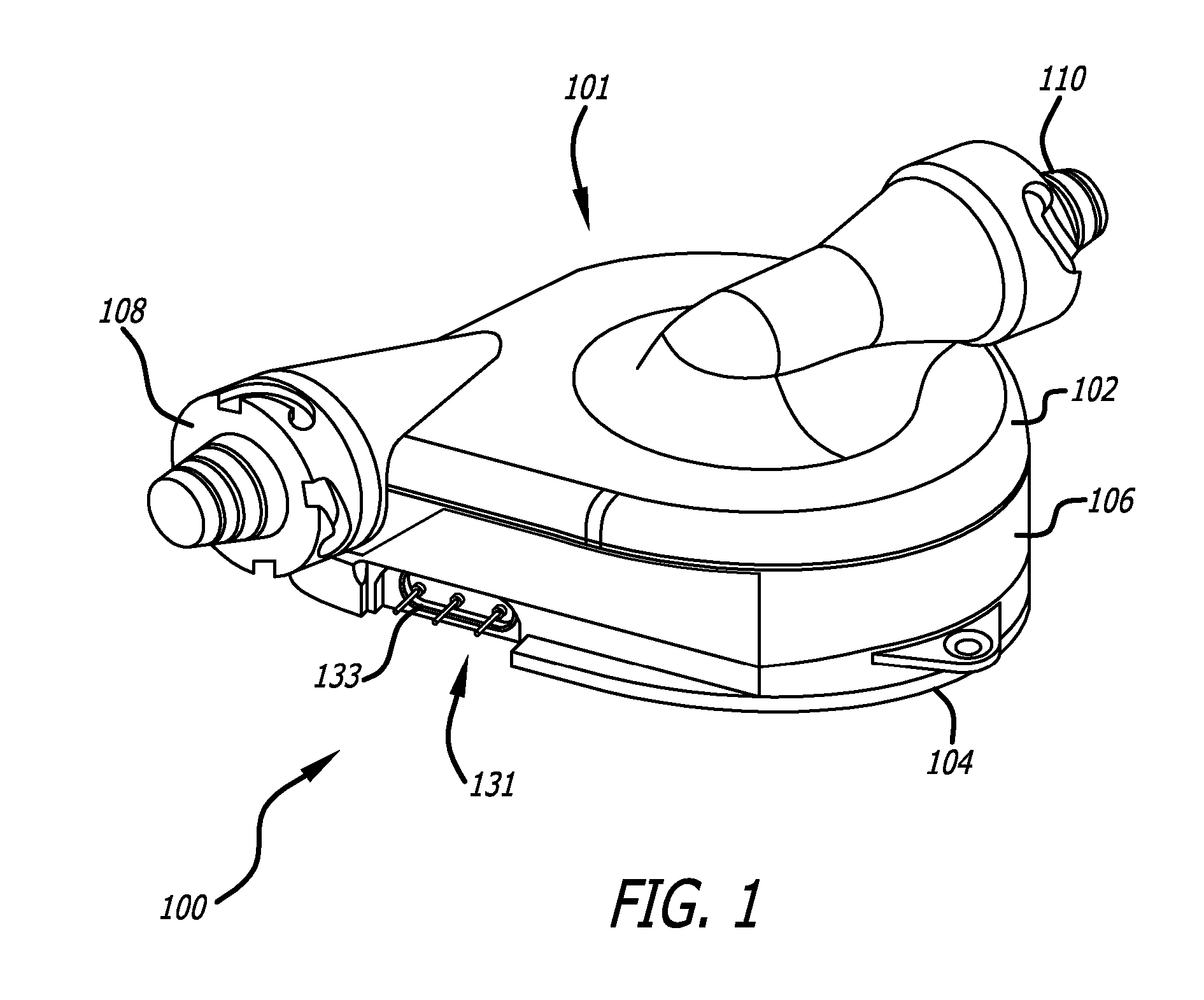

[0109]FIG. 1 illustrates a preferred embodiment of a rotary blood pump 100 according to the present invention. The rotary blood pump 100 is coupled to the circulatory system of a patient, allowing blood to enter through an inlet 110 then exit a short time later through an outlet 108.

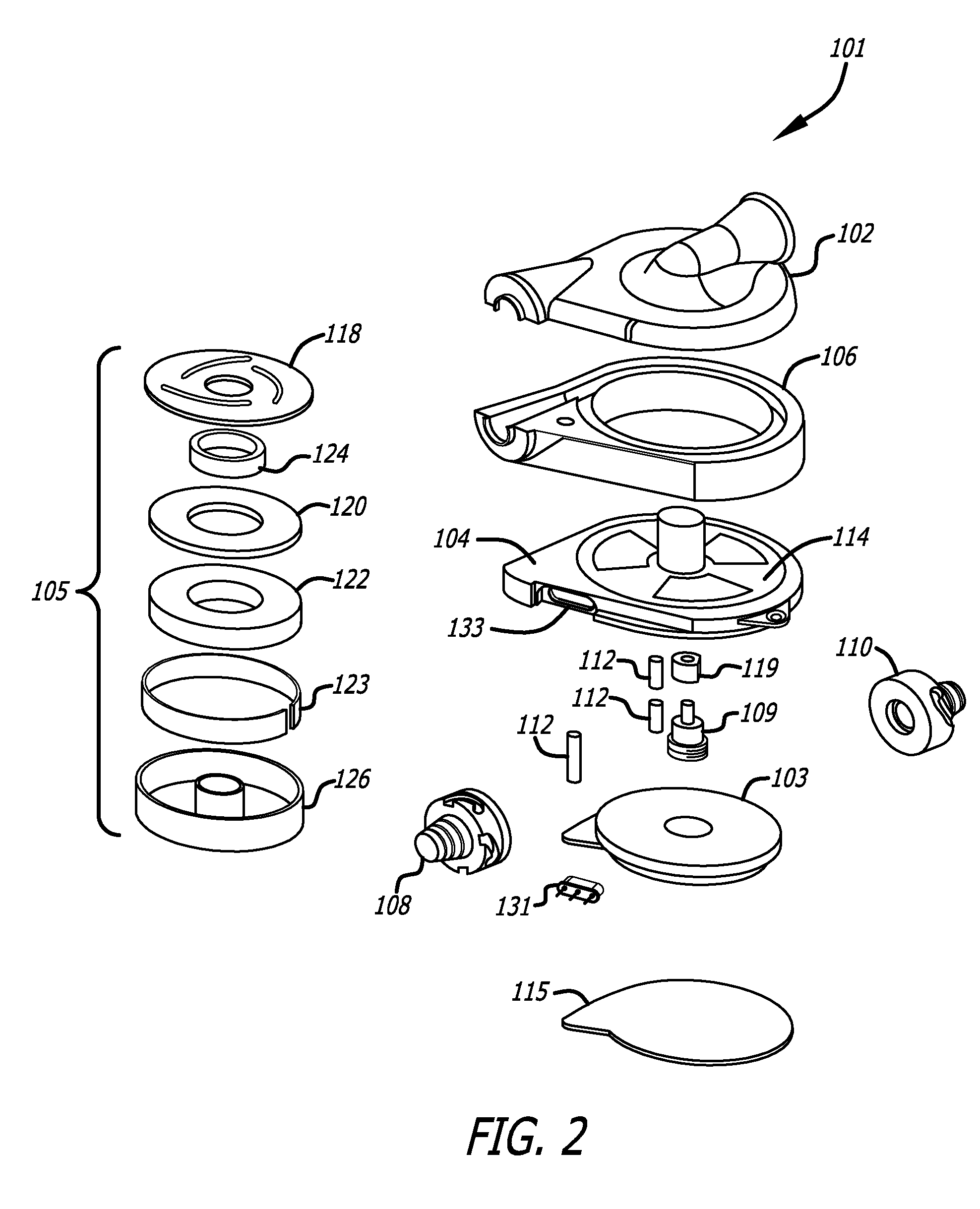

[0110] Blood is primarily driven through the rotary blood pump 100 by a rotor assembly 105 within a housing assembly 101, as seen in FIG. 2. The rotor assembly 105 is not physically connected to the housing assembly 101. Instead, the rotor assembly 105 is supported by an axial hydrodynamic bearing created between a thrust plate 114 and a bottom surface of the rotor assembly 105, a radial hydrodynamic bearing between the inside diameter of the rotor assembly 105 and the outside diameter of the spindle portion of the thrust plate 114 (or, in the alternative, between the outside of the rotor assembly 105 and the inside diameter of the housing assembly 101), and by an axial magnetic bearing created between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com