System and apparatus for enclosing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

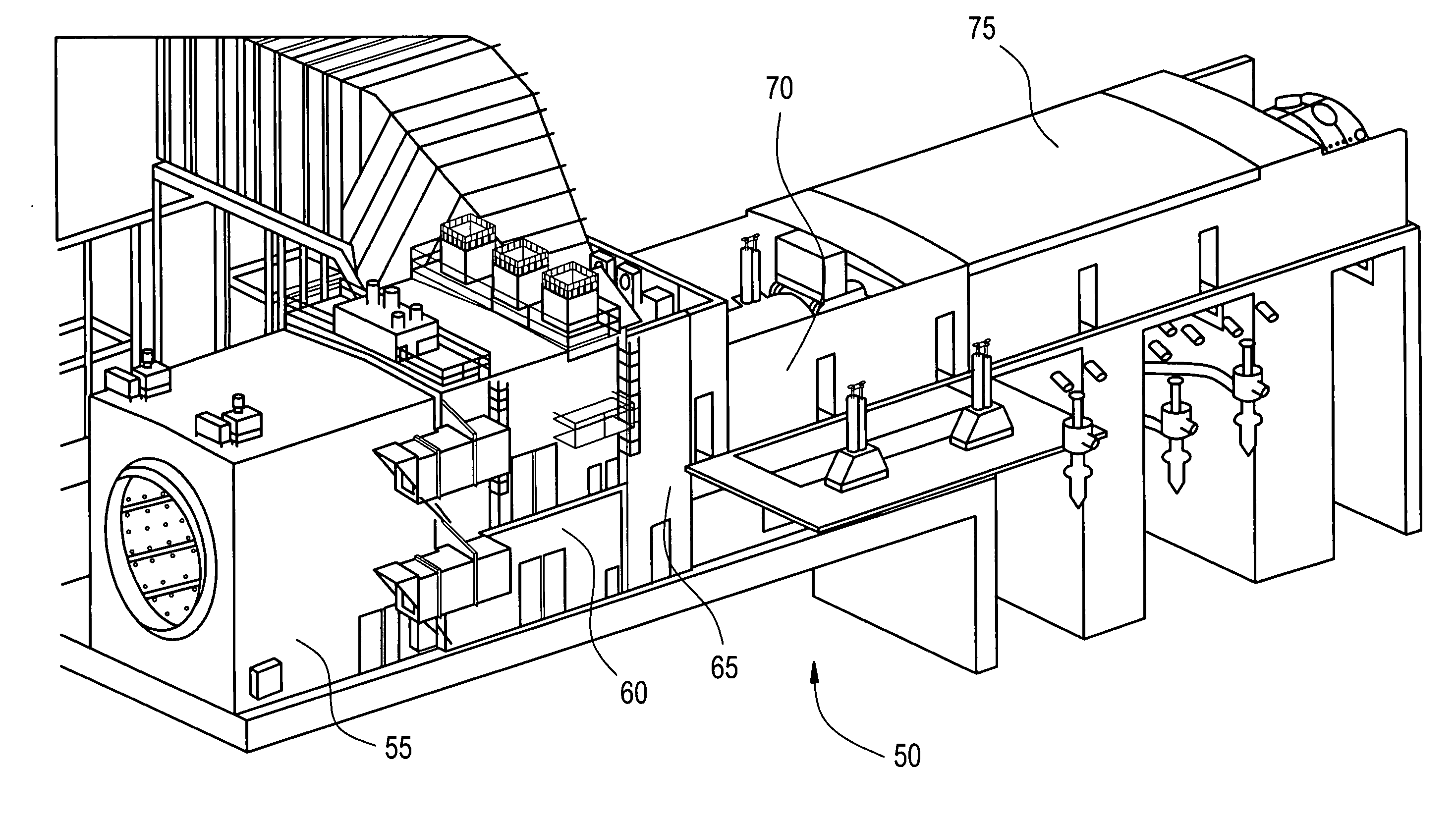

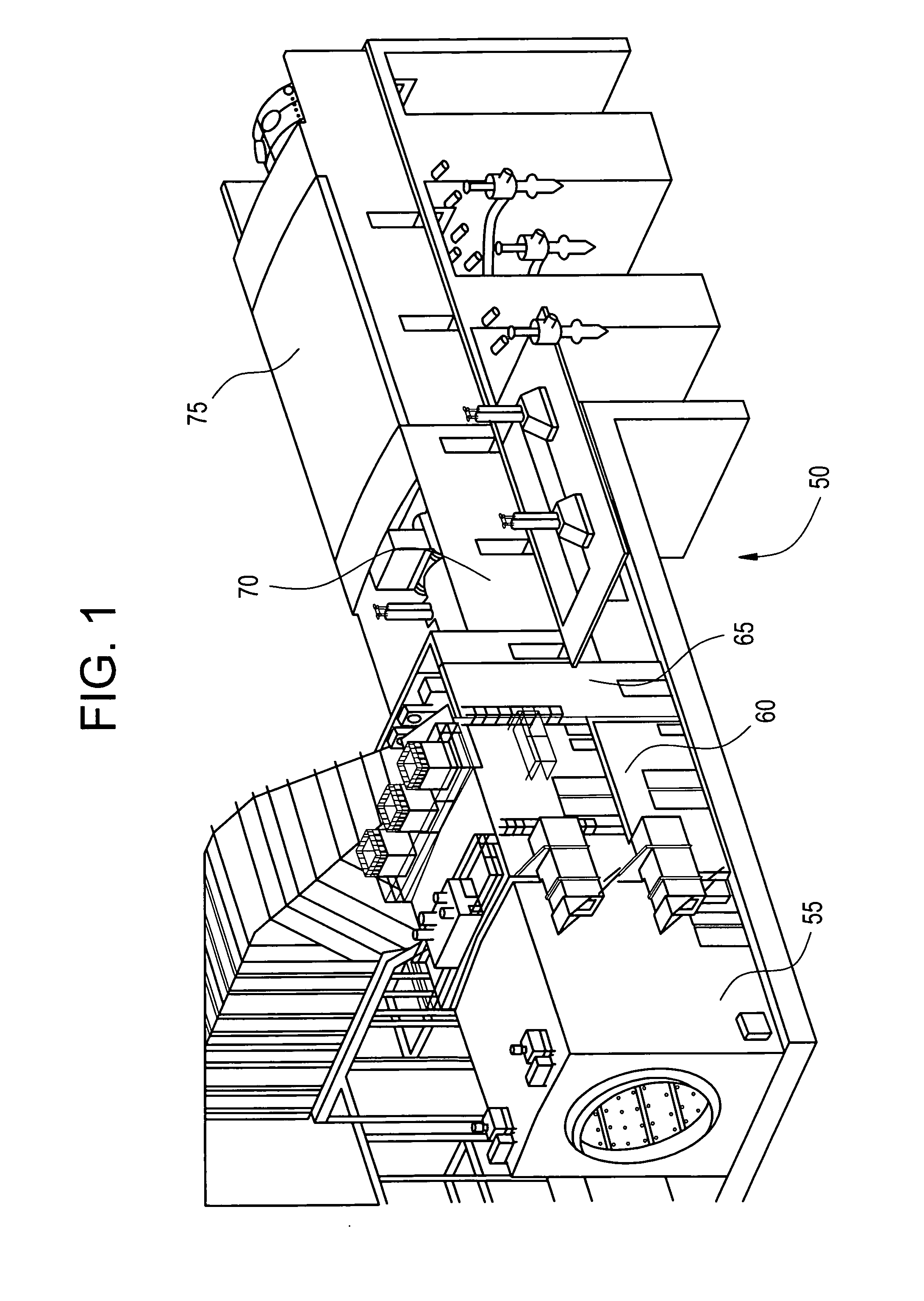

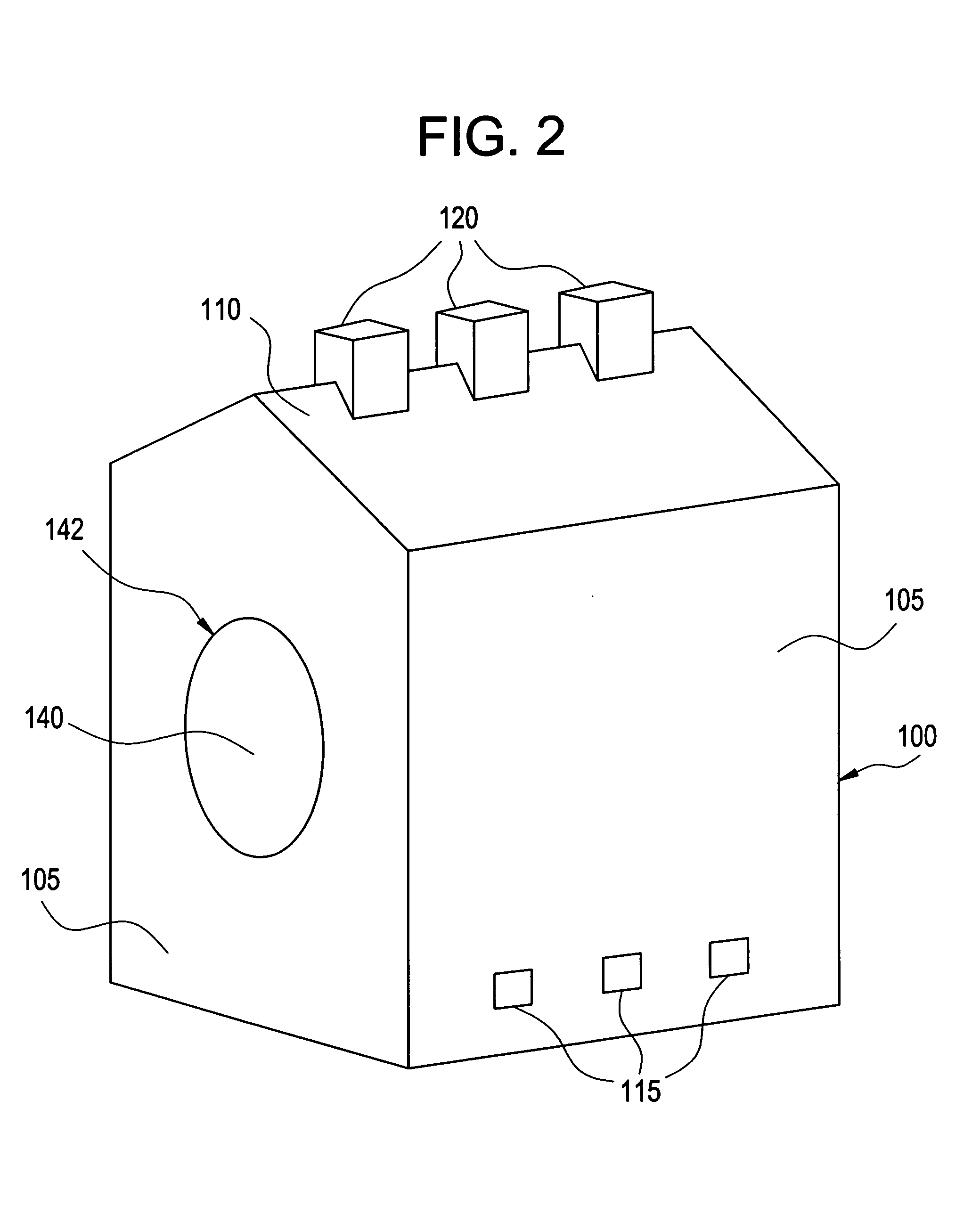

[0012] An embodiment of the invention provides a naturally ventilated power plant equipment enclosure, employing natural convection as opposed to forced convection. The enclosure is designed to limit the transmission of acoustic energy generated by the equipment, while maintaining appropriate thermal conditions for operation of the equipment. In an embodiment, the enclosure includes ventilation inlets near the enclosure bottom and ventilation outlets near the enclosure top. The inlets may be located on or near the floor or at or near the bottom of the enclosure sidewalls. The outlets may be positioned on the enclosure roof or near the top of the enclosure sidewalls. In an embodiment, outlets may be located on the top of a pitched roof to drive maximum buoyancy flow through the enclosure. If outlets are not disposed on the enclosure top, due to an obstruction for example, or for reasons relating to the desire to use the enclosure top as a storage area, for example, ventilation outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com